179

COOLING SYSTEM

OPERATION

9

OPERATION

All models use a two-stage cooling system

design. The cooling system is dependent on water

pump pressure and controlled by thermost at and

pressure valve operation.

Restricted or inadequate water flow

through the outboard reduces cooling system

performance and may lead to severe power-

head damage.

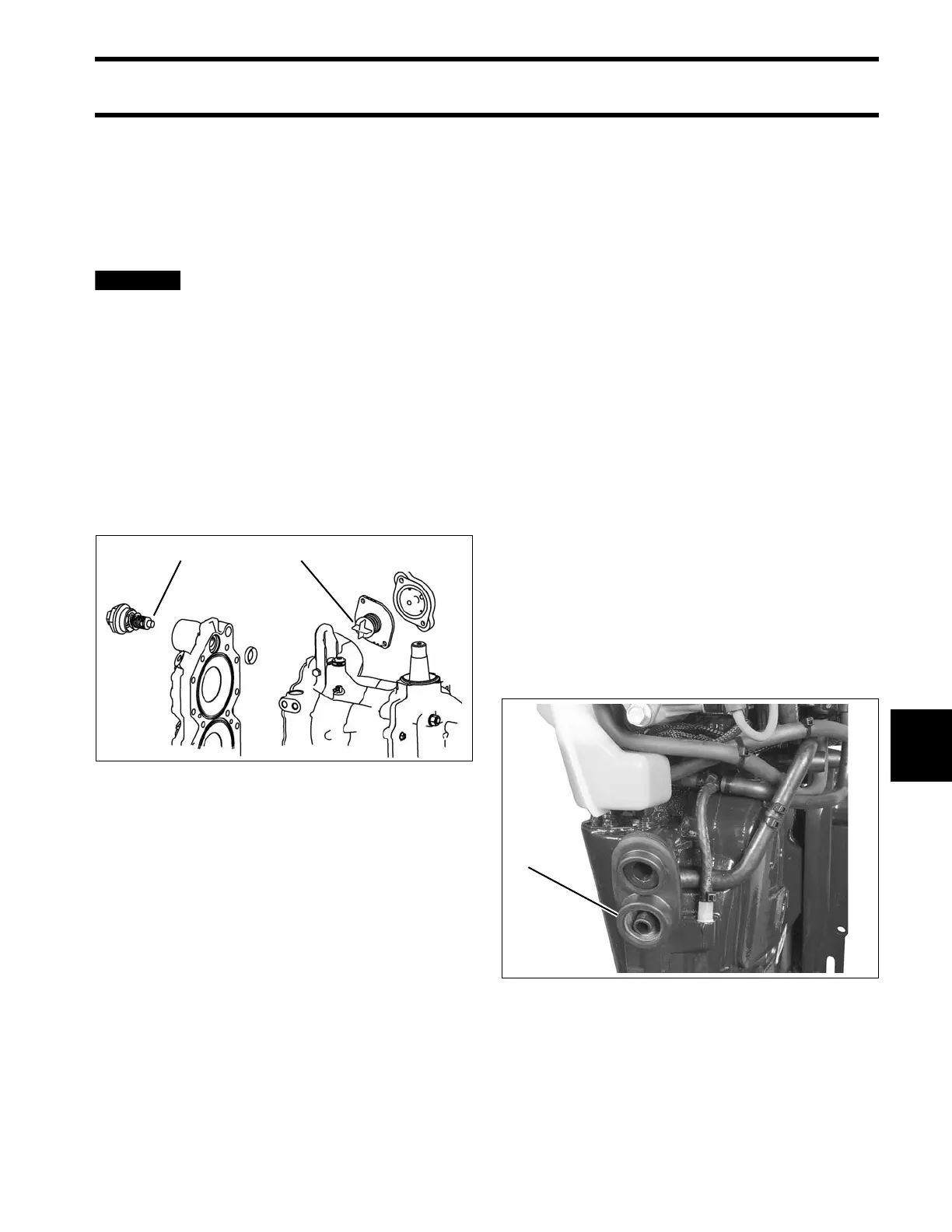

Cylinder Block / Cylinder Head

Cooling

The flow of water throu gh the cylinder block and

cylinder head is controlled by a the rmostat and a

pressure relief valve. The pressure valve is

located in the top of the block next to the exhaust

cover.

The thermost at and pr essure valve co ntrol the

flow of water entering the vertical water passages

of the cylinder head.

At low speed, the pressure valve is aga inst the

seat and the thermost at is closed. W arm water

from the cylinder block gradua lly mig rates to the

thermostat pocket at the top of the cylinder head.

The thermostat opens when the water temp era-

ture reaches approximately 143°F (62°C).

When t he t hermostat opens, wat er flows down

through the cylinder head to a passage in the cyl-

inder block. W ater flows through the block to the

exhaust housing and then out of the outboard.

At higher speeds, wate r pressure op ens th e

pressure relief valve at approximately 1800 RPM.

Water flows through the valve to the cylinder head

and byp asses the th ermostat. All wa ter flo ws

through the cylinder head to the outlet passage of

the blo ck and the n exit s through the exhaust

housing.

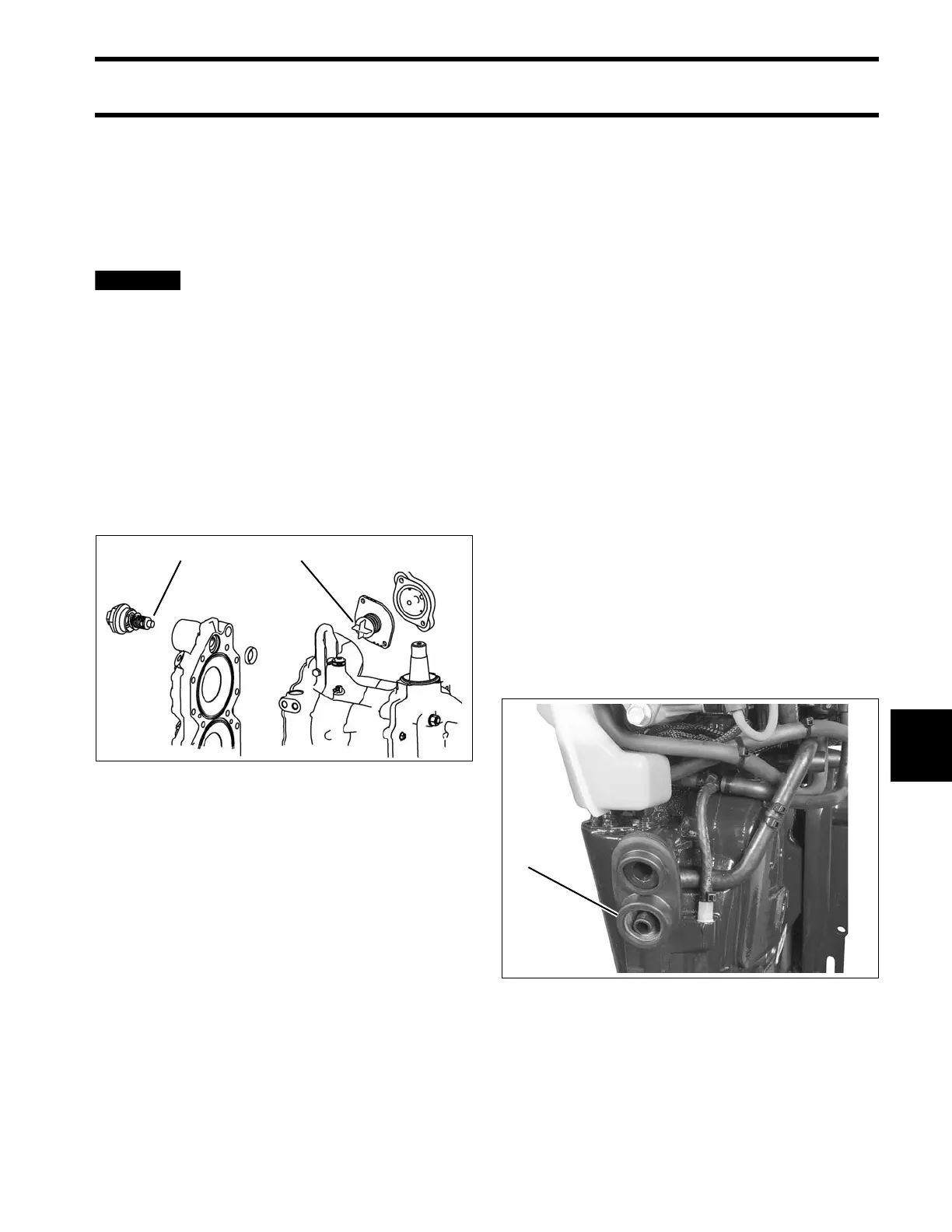

EMM and Vapor Separator

Cooling

Cooling water is routed from the top of the cylinder

block to t he inlet fitting o f the EMM water cavity.

Cooling of the EMM helps to stabilize the temper-

atures of internal components.

IMPORTANT: Improper EMM cooling will acti-

vate service cod es 25 and 29 and the Engin e

Monitor warnin g system. Refer to the EMM Ser-

vice Code Chart at the back of this manual for

specific service code information.

Cooling water from the EMM is routed to the water

inlet fit ting of the vapor separator water cavity .

Cooling the vapor sep arator fuel chamb er mini-

mizes fuel vaporization.

Cooling water from the vapor sep arator is route d

to the overboard indicator.

1. Thermostat

2. Pressure valve assembly

002441

1. Overboard indicator 004969

Loading...

Loading...