341

GEARCASE SERVICE, 75 – 90 HP MODELS

GEARCASE ASSEMBLY

12

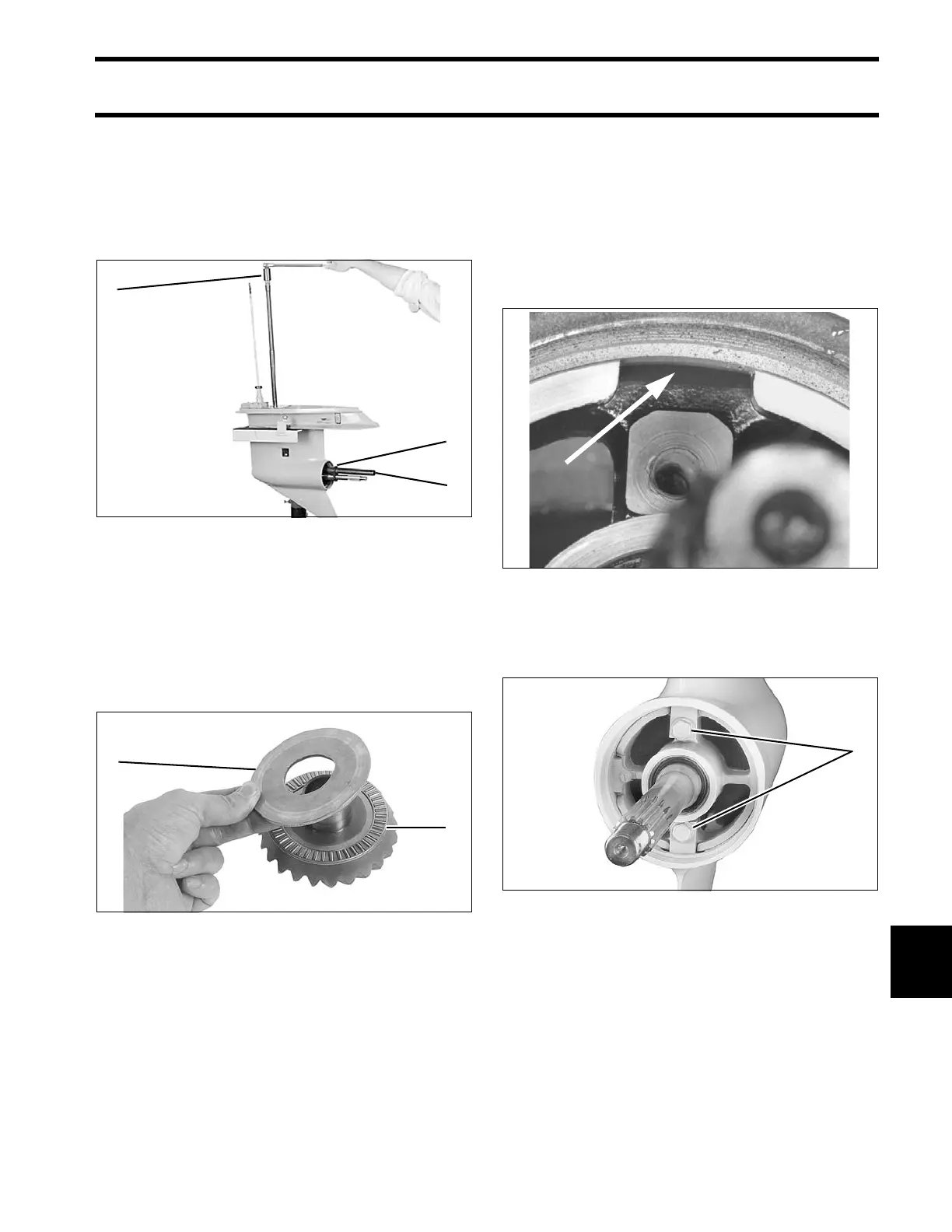

Use Driveshaft Holding Socket, P/N 311875, Pin-

ion Nut Hold er, P/N 334455, and W rench

Retainer, P/N 341438, to tigh ten the pinion nut to

a torqu e of 100 to 110 ft. lb s. (136 to 149 N·m).

Pad handle o f ho lder to pr event damage to

gearcase.

Propeller Shaft Bearing Housing

and Gear Installation

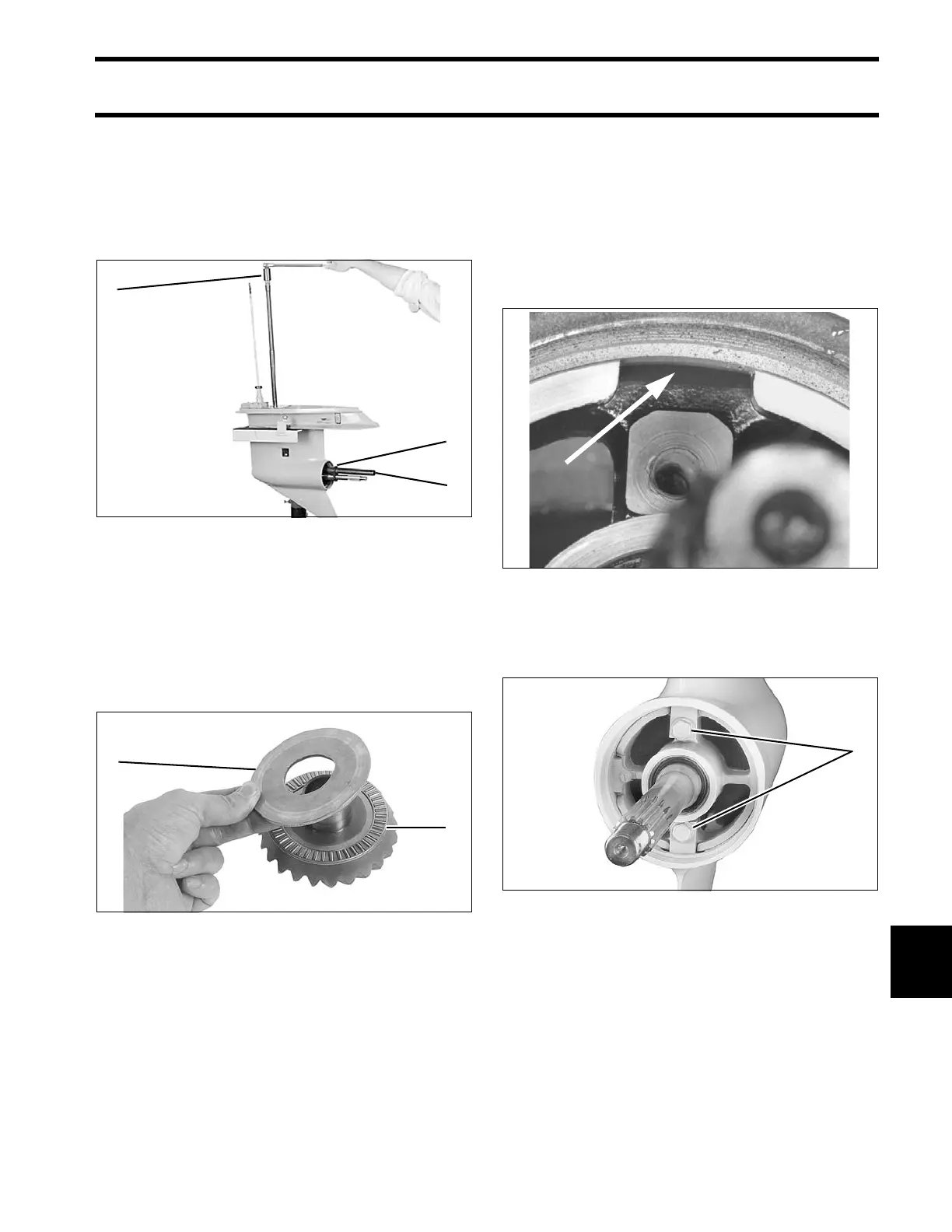

Oil and install thrust bearing and thrust washer on

hub of reverse gear. Slide the gear assembly onto

the propeller shaft until it engages the pinion gear.

Lightly apply Gasket Sealing Compound to a new

bearing housing O-ring. Install O-ring in groove in

the housing.

Install hou sing into ge arcase. Align screw holes

with retainer slots in gearcase.

Housing mu st be completely sea ted to install

retainer tabs.

Install two ret ainers, washers an d scr ews. Apply

Ultra Lock to th reads and tighte n scr ews to a

torque of 18 to 20 ft. lbs. (24 to 27 N·m).

1. Holding socket

2. Pinion holder

3. Retainer

42229

1. Thrust bearing

2. Thrust washer

DSC02295

Retainer Tab Notch 50106a

1. Retainer tab screws 001989

Loading...

Loading...