319

GEARCASE SERVICE, 75 – 90 HP MODELS

GEARCASE REMOVAL AND INSTALLATION

12

Gearcase Installation

Before installing gearcase, shift rod

adjustment MUST be checked. Refer to SHIFT

ROD ADJUSTMENT on p. 323.

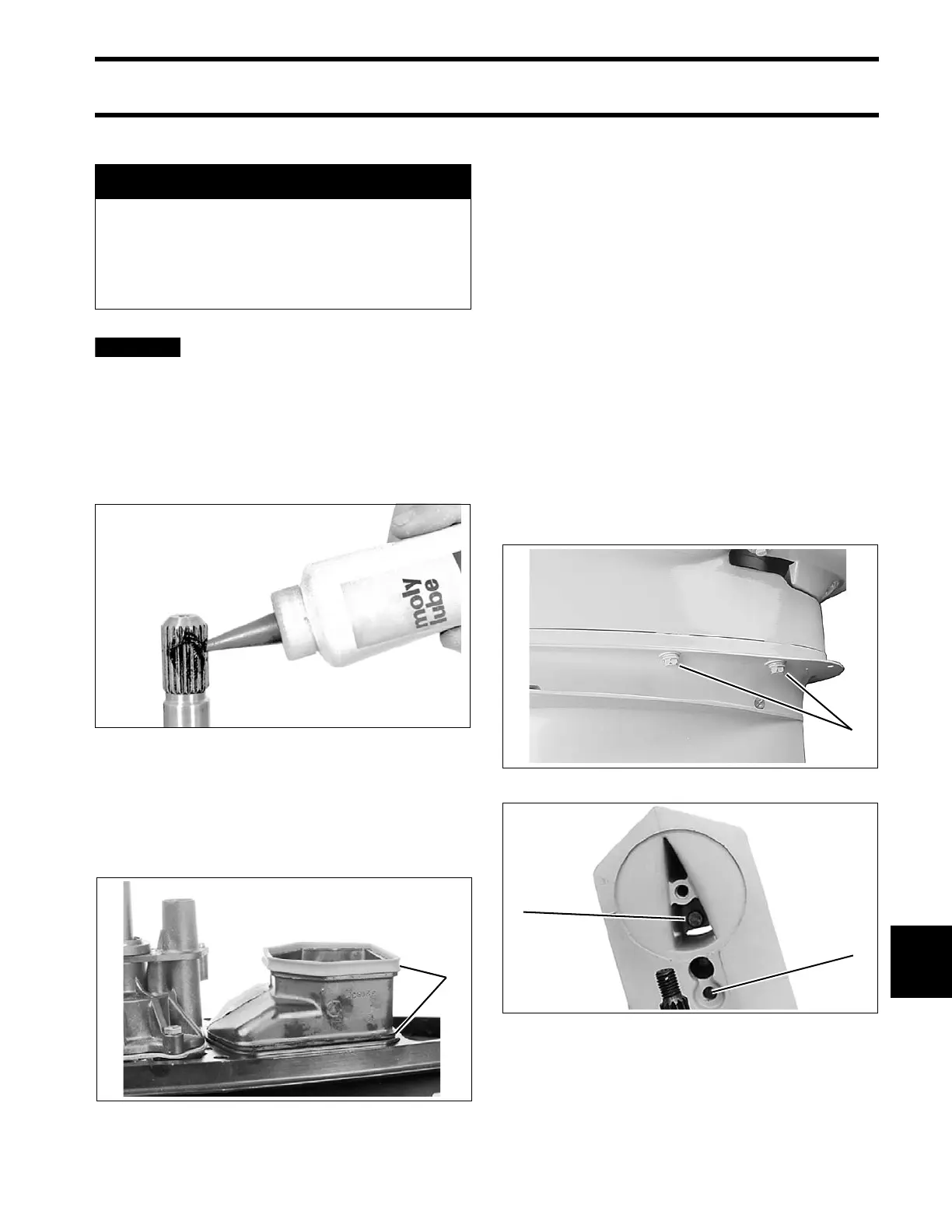

Coat th e drivesh aft splines with Moly Lube. DO

NOT co at top su rface of th e driveshaf t be cause

lubricant may prevent seat ing of the driveshaf t in

the crankshaft.

Apply Adhesive 847 to the lower exhaust housing

seals’ inner surfaces. Place two new seals on the

housing. Apply Triple-Guard grease to the seals’

outer surfaces and pla ce the housing on the

gearcase.

Slide the gearcase into place, making sure:

• Driveshaft engages the crankshaft.

• Water tube enters the water pump.

• Lower inner exhaust housing installs correctly.

• Shift ro d does not turn an d is positio ned prop-

erly in the shift rod lever below the crankcase.

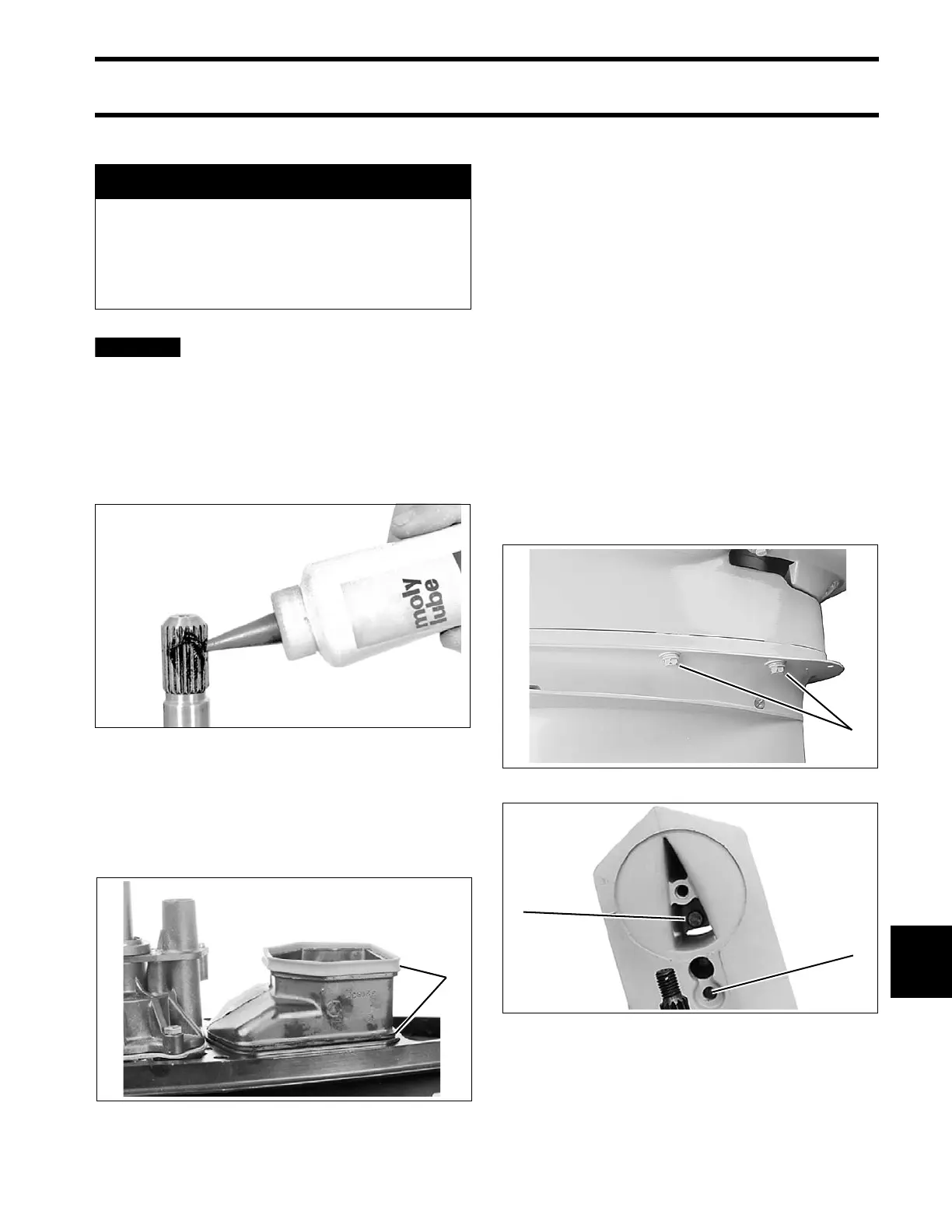

IMPORTANT: New gearcase screws are treated

with a thread-locking material. Apply Triple-Guard

grease t o threa ds to ensure tha t the correct

clamping force is achieve d when tightening—If a

previously installed screw is re-use d, use a wire

brush to remove any old thread-locking material or

corrosion and lubricate threads with Triple-Guard

grease.

Install screws and washers and tighten to a torque

of:

• 3/8 in. screws – 26 to 28 ft. lbs. (35 to 38 N·m)

• 7/16 in. screws – 45 to 50 ft. lbs. (61 to 68 N·m)

A WARNING

During service, the outboard may drop

unexpectedly. Avoid personal injury;

always support the outboard’s weight with

a suitable hoist or the tilt support bracket

during service.

30385

1. Lower exhaust seals 32002

1. 3/8 in. screws 001990

1. 3/8 in screw

2. 7/16 in. screw

COA3139

Loading...

Loading...