COMMISSIONING

Part No.: 4417340 Revision 1 Service Manual 63

954 SmartServo FlexLine

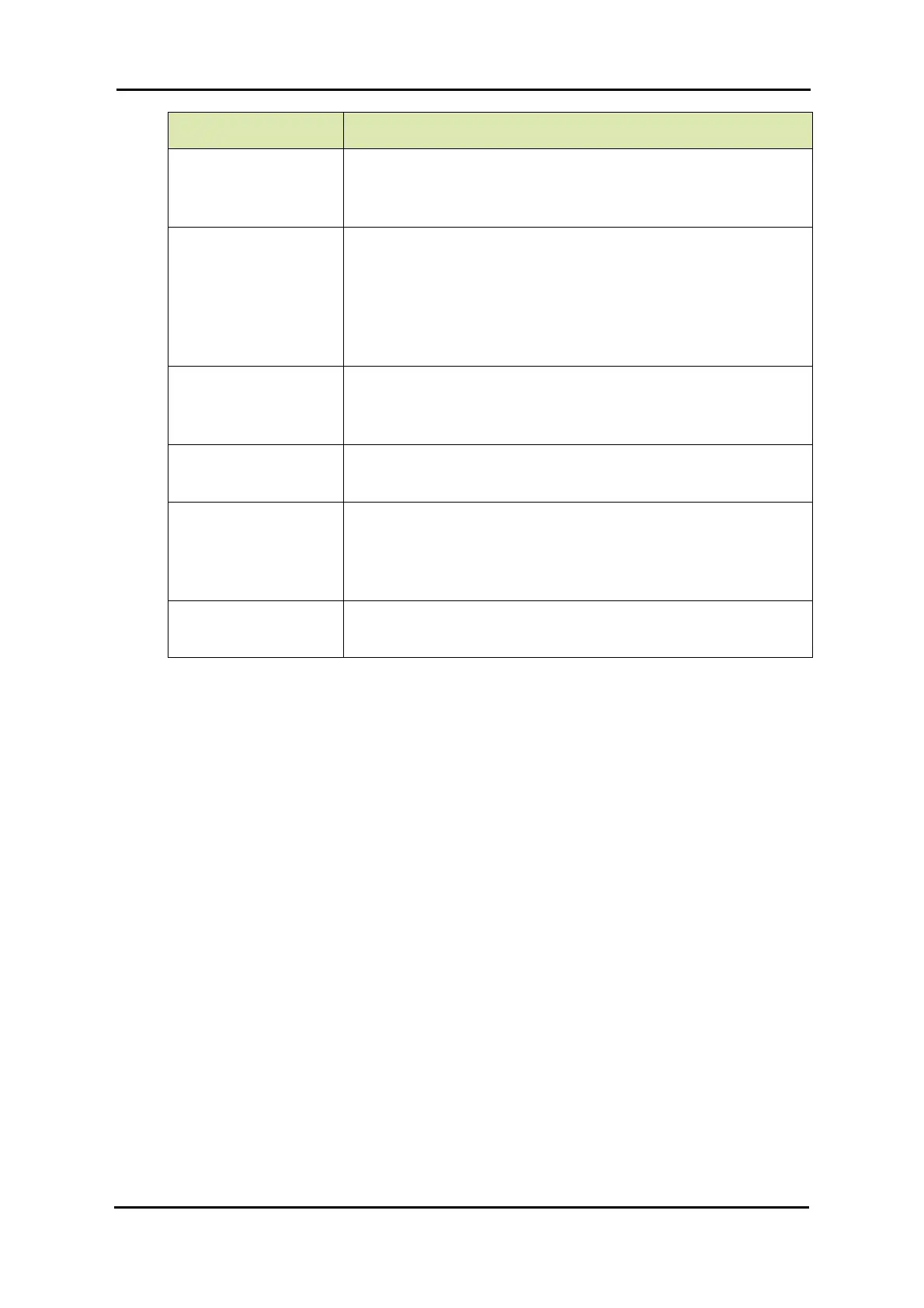

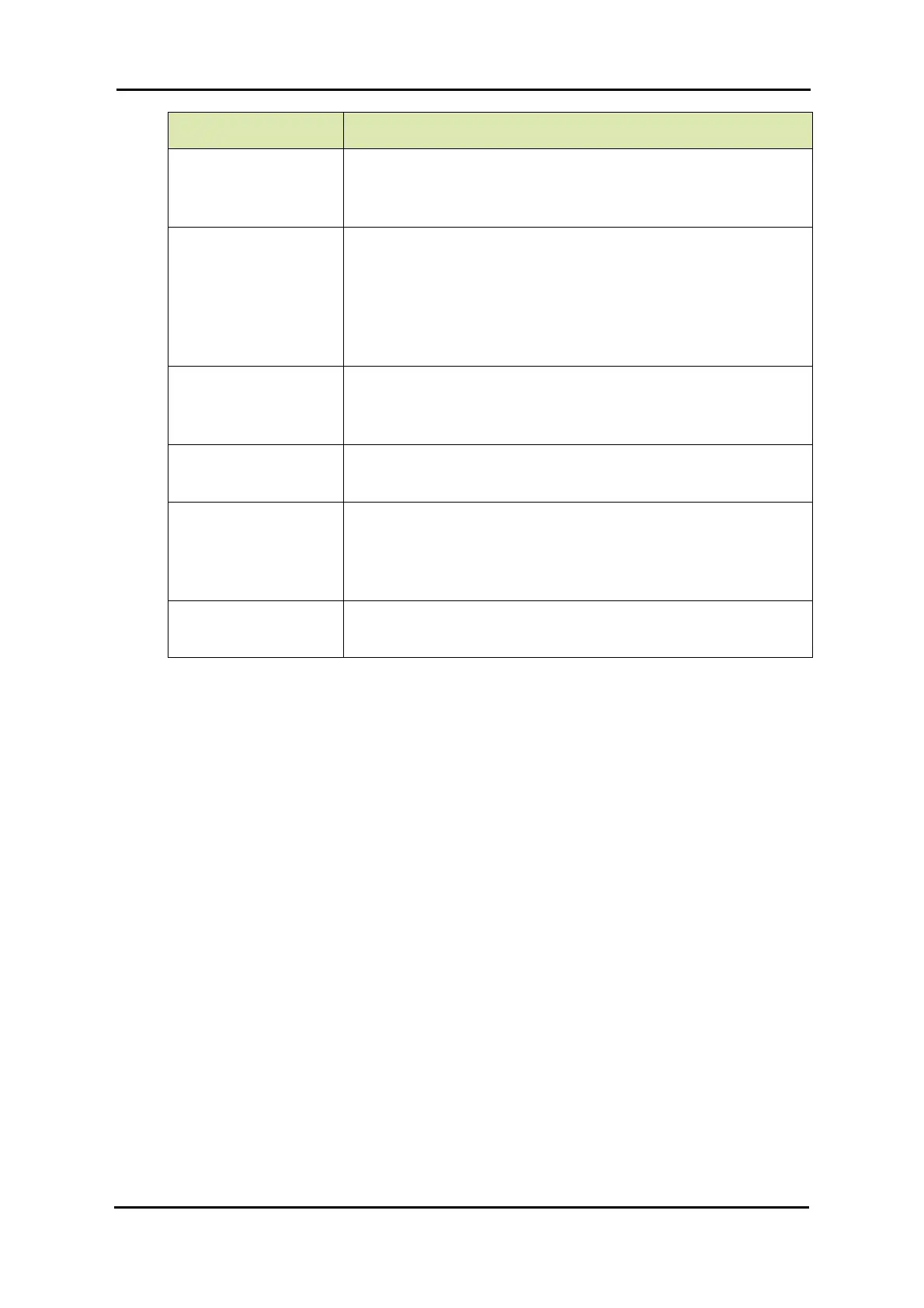

Element Description

temperature dependency of the magnetic field. By this magnet

temperature measurement, the firmware compensates the level

calculation.

W&M jumper Weight and Measures jumper or switch located on every

FlexConn board for protecting modification of W&M relevant

entities (device parameters) and firmware. The W&M status is

daisy chained to the other boards so only one of the boards need

to be set to protect / seal status and all other boards will read that

protect / seal status.

External watchdog In addition to an internal watchdog in the micro controller the

CAN-SERVO board implements an external watchdog in order to

improve the SIL hardware FMEDA figures.

RTC Real Time Clock used for date and time stamping of

measurements and diagnostics.

Low power Signal generated by the CAN-SERVO board in case the power

drops below a certain threshold where the firmware needs stop

the servo stepper motor and store relevant operational data in

non-volatile memory e.g. motor position.

NV memory Non-volatile memory to store diagnostic data, operational data

(e.g. motor position) and configuration parameters (entities).

The TII-SRV firmware supports the following process data

measurements reflected in a Primary Variable (FlexConn PV):

• Displacer level (innage, ullage is in Secondary Variable)

• Product level (innage, ullage is in Secondary Variable)

• Interface level (innage, ullage is in Secondary Variable)

• Water level (innage, ullage is in Secondary Variable)

• Average density

The TII-SRV firmware supports the following operational modes:

• Interface 1 (vapor – product interface)

• Interface 2 (product – product interface)

• Interface 3 (product – water interface)

• Dip mode (vapor – product interface, avoiding contamination or

damaging of the displacer)

Loading...

Loading...