Engine System - LPG 158Service Manual – CS7000

Circuit Descriptions

Ignition System

The ignition system consists of a spark control module (aka Ignitor), three ignition coils, and a crank position

sensor. The crank position sensor reads a rotating 6 toothed ring which is mounted on the ywheel between

the ywheel and the engine.

The heart of the system is the spark control module. It controls the current ow of each ignition coil primary

circuit in order to control when spark occurs based on inputs from the crank position sensor. Each coil res

twice per cylinder cycle. Once to initiate the power stroke and once in exhaust stroke (waste spark)

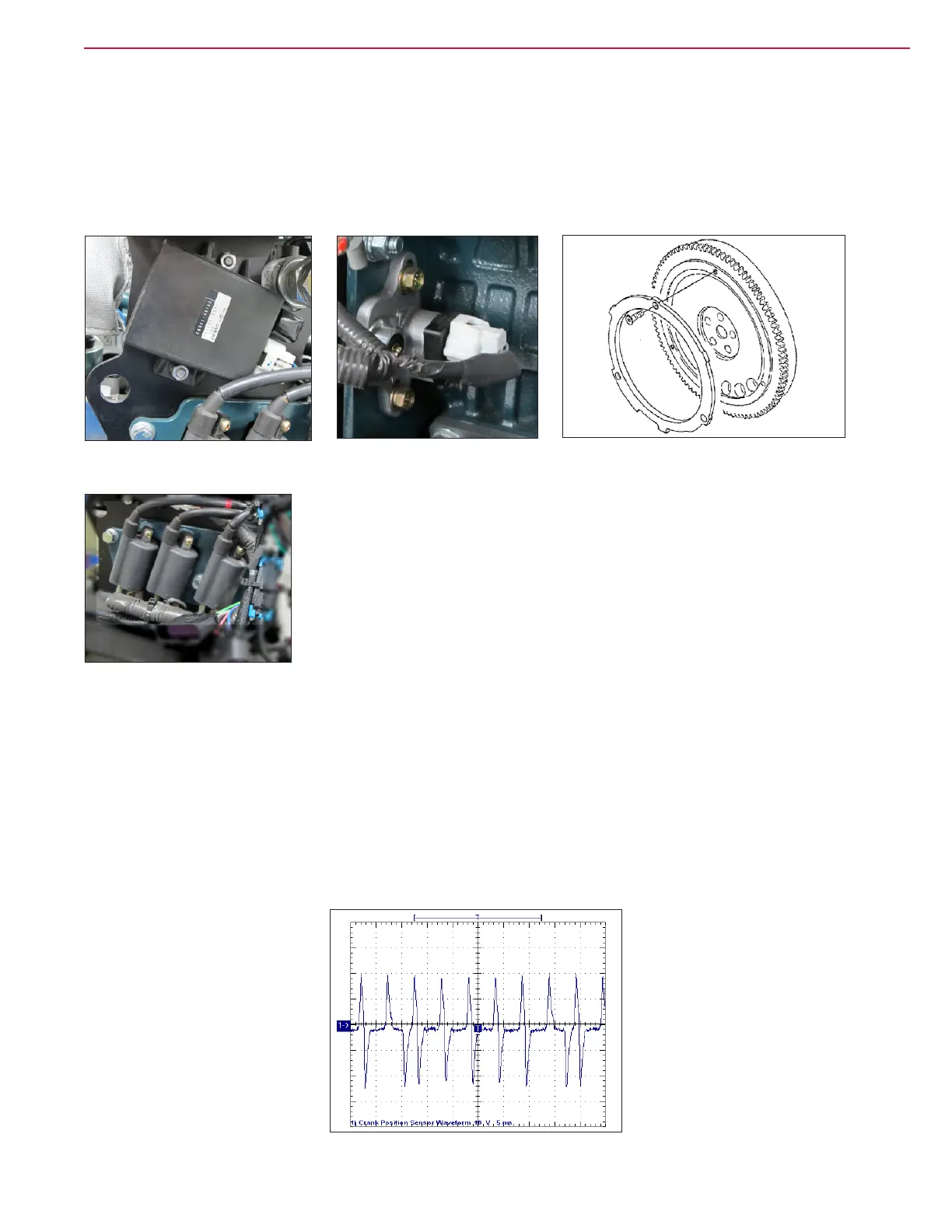

The crank sensor is a two wire “ AC pulse generator”. It has a wire coil inside of it. As the toothed ring

rotates, the teeth pass in line with the end of the sensor tip. This induces a voltage spike that the spark

control module can “read” as cylinder position information. The number of spikes per minute is translated as

engine RPM. One tooth on the ring is wider than the other ve. This creates a unique “spike” so that the

spark control module can distinguish the cylinders from one another. This allows it to re the right ignition

coil at the right time. Below is what the crank sensor wave form looks like on an oscilloscope. Notice that

every sixth pattern is “wide”.

Crank Position Sensor

Spark Control module

Toothed Ring and ywheel

Ignition Coils

WaveStar : Cougar Crank Sensor Waveform Page: 1

Loading...

Loading...