Scrub System 316Service Manual – CS7000

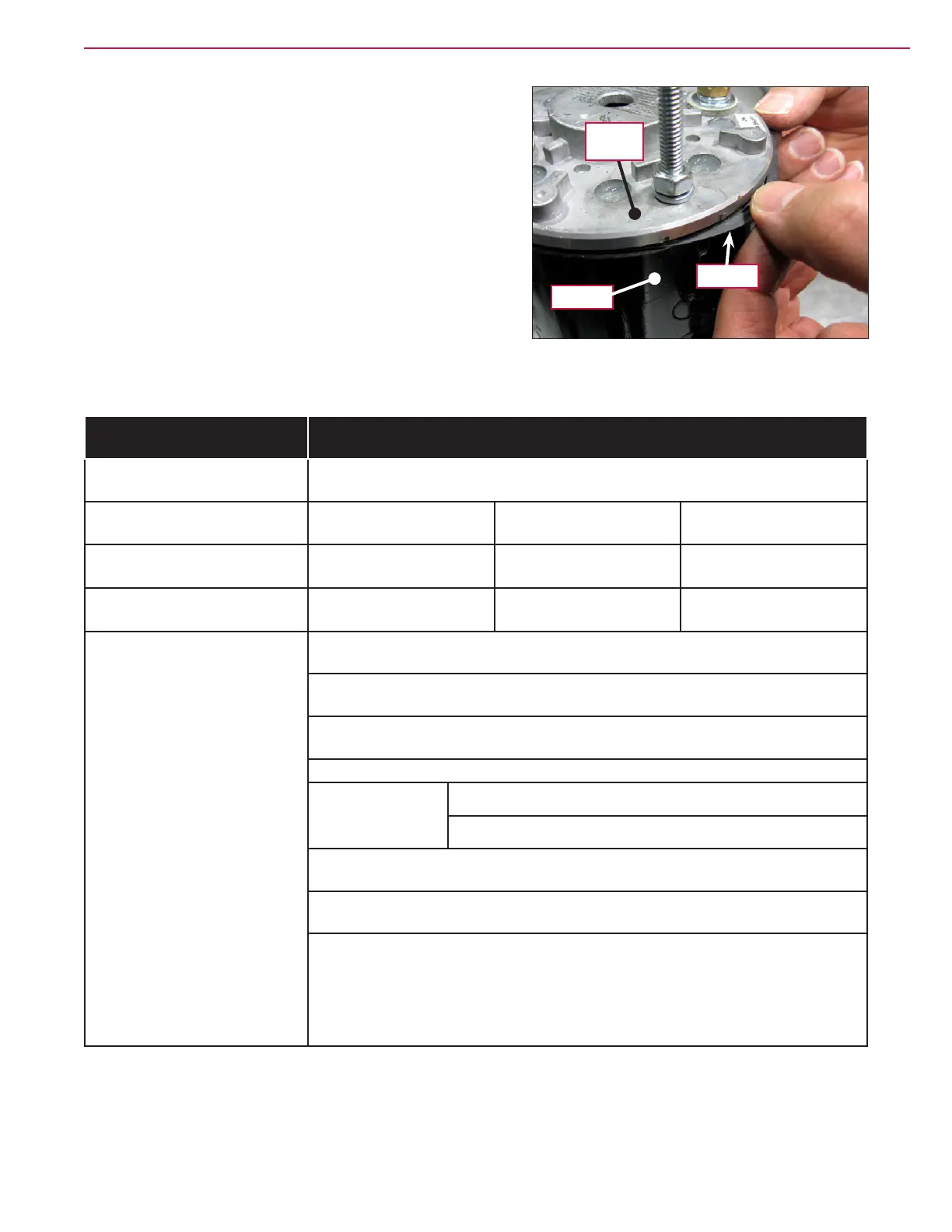

d. Carefully install a new Gasket between the Frame

and the End Casting. Make sure the Gasket is

seated at on the mating surfaces.

e. Once the Gasket is installed, fully seat the End

Casting

onto the Frame.

f. Tighten the hex nuts.

13. Reinstall the terminals and top terminal nuts, then

reinstall the terminal cover and acorn nuts.

14. Seal the retaining wire holes in the end cover with

silicone sealant.

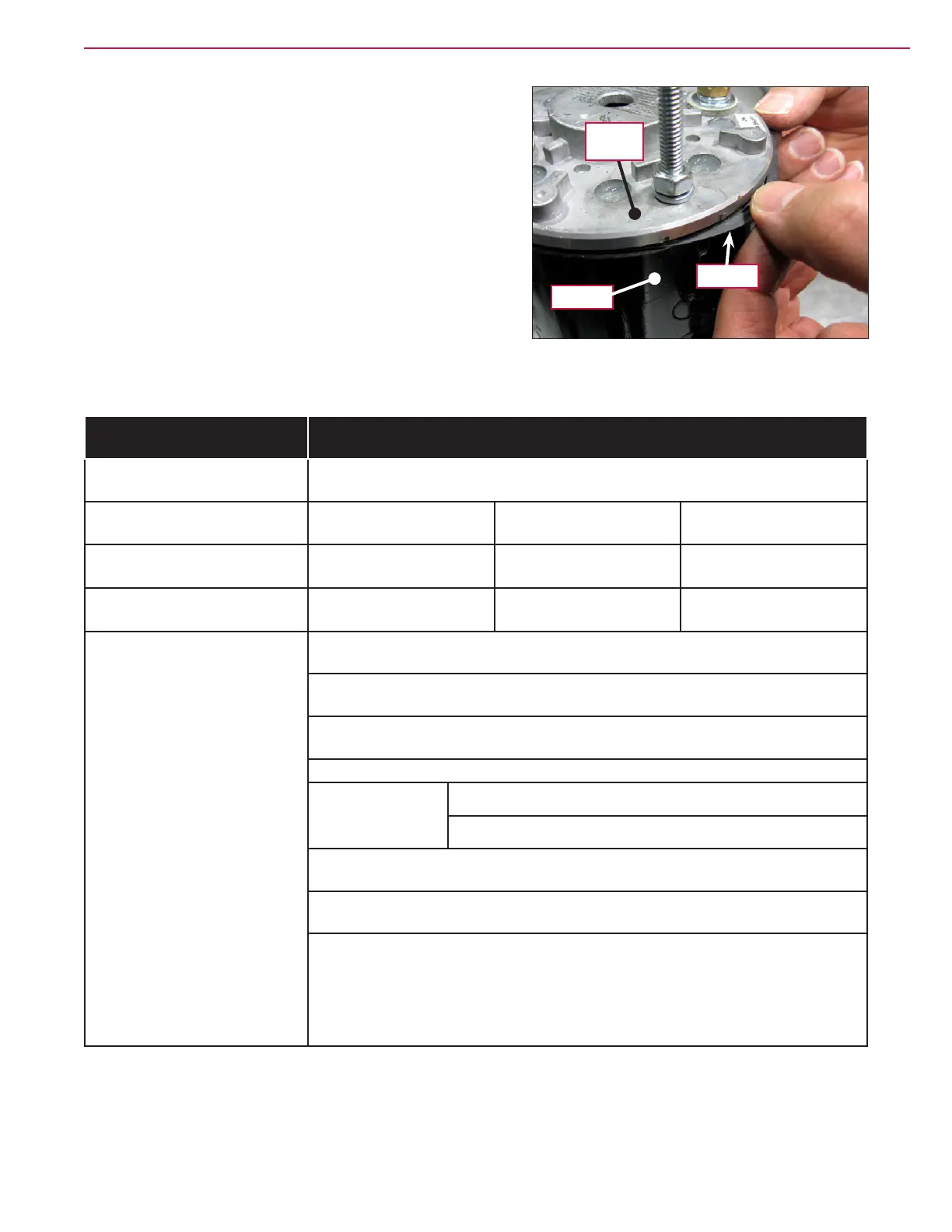

Specications

Component Specications

Scrub Brush Motors (all) 35 VDC, 1 HP, 2750 RPM, 26 Amp

Scrub Brush Motor -

Center

Current Draw (shop

measurements)

Average - 19 Amps Max. - 37 Amps

Scrub Brush Motor - Left

Current Draw (shop

measurements)

Average - 17 Amps Max. - 23 Amps

Scrub Brush Motor - Right

Current Draw (shop

measurements)

Average - 17 Amps Max. - 26 Amps

Deck Actuator Motor

Input Voltage - 34-40 VDC

Dynamic Load - 500 lbs. max.

Static Load - 1000 lbs. max.

Restraining Torque - 100 in.-lbs. min.

Current Draw

9 Amps max at rated dynamic load

2-5 Amps Typical

End of Stroke - Ball detent clutch with a load rating between 600 and 1000

lbs.; will ratchet at end of stroke

Thermal Protection - Automatic resetting thermal breaker enclosed in motor

housing.

Wiring Polarity:

• To extend actuator, connect red lead to positive and yellow lead to

negative.

• To retract actuator, connect yellow lead to positive and red lead to

negative.

Frame

Gasket

End

Casting

Loading...

Loading...