Wheel System, Non-traction 439Service Manual – CS7000

6. If steps 1 through 5 don’t provide adequate

adjustment, remove the wheel and adjust the

Rod End as follows:

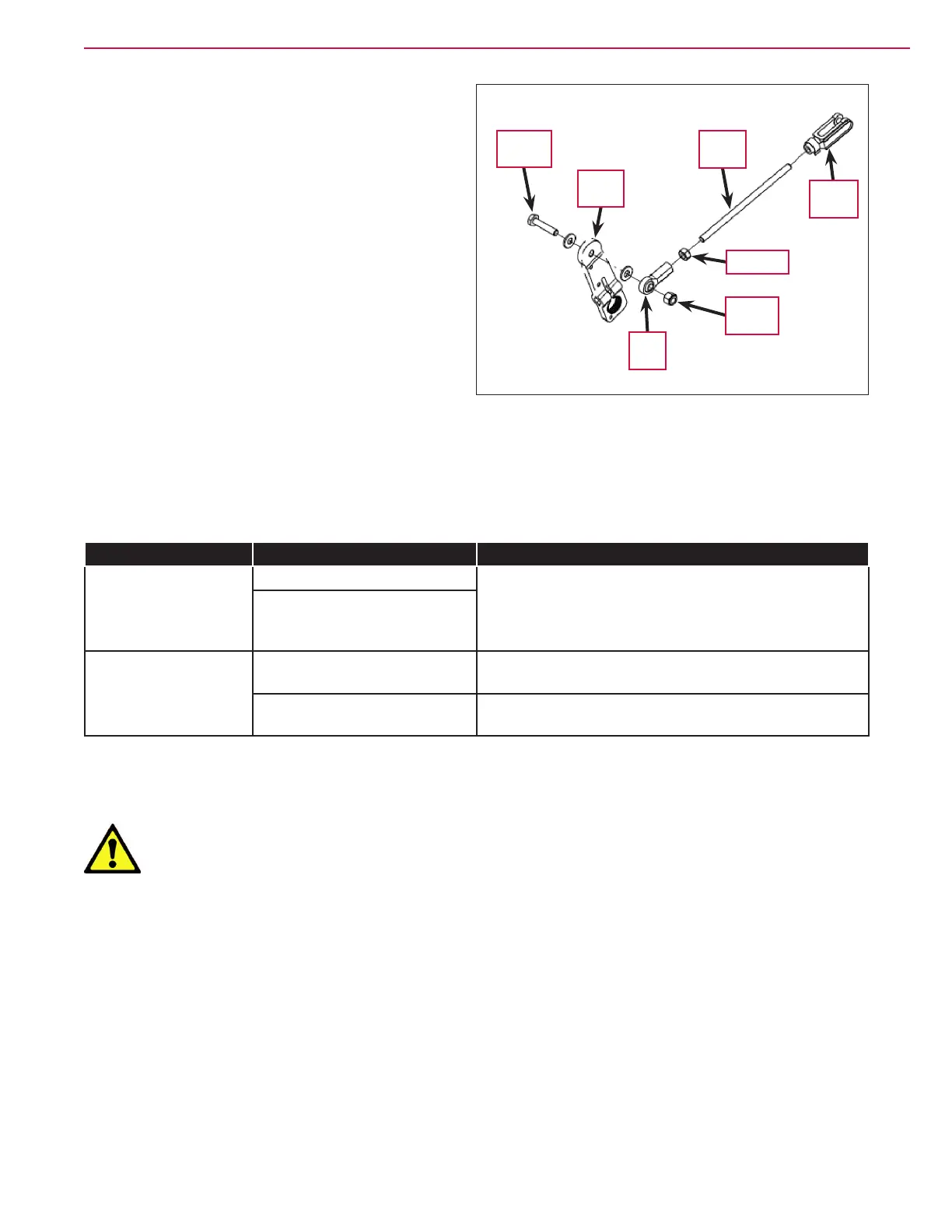

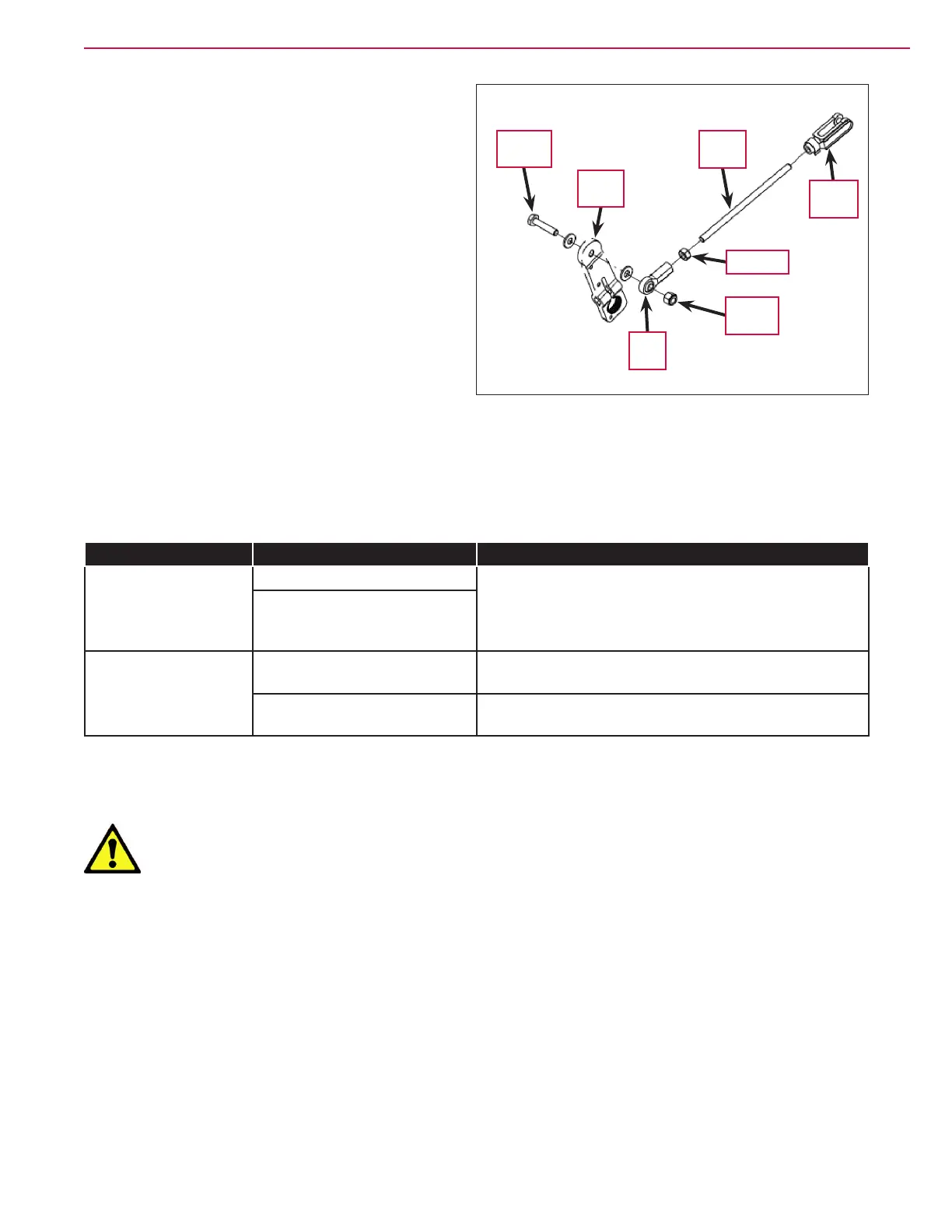

a. Remove the Nyloc

™

Nut, 1/4”-20 Bolt and

washers holding the Rod End to the Brake

Lever

.

b. Loosen the Locknut.

c. Rotate the Rod End on the Brake Rod to

effectively lengthen or shorten the Brake

Rod

. Note that lengthening the Brake Rod

will apply more pressure to the brakes

with comparable brake pedal travel.

d. When the brake is adjusted correctly,

tighten the Locknut, then reinstall the Rod

End

onto the Brake Lever.

e. Reinstall the wheel.

Troubleshooting

Problem Cause Correction

The wheels are

making excess noise.

The wheel bearings worn. Check the wheel, wheel bearings, and brake and

spindle assembly and replace as required.

The wheel and/or brake

and spindle assembly are

damaged.

The brakes are not

working correctly.

The brakes are out of

adjustment

Adjust the brakes.

The brake linings are worn

out.

Replace the brake linings.

Removal and Installation

Warning! Before performing any maintenance or adjustments, make sure the key switch is off

and the key is removed from the machine. Chock the machine wheels to prevent the

machine from moving. Never work under a machine without safety stands or blocks

to support the machine. When jacking the machine, do so at the designated Tie

Down/Jacking Locations.

To Remove and Reinstall a Wheel

1. Jack up the machine at a designated jacking point.

2. Install safety stands or blocks to support the machine while you work on it.

Brake

Lever

Rod

End

Locknut

Brake

Rod

Clevis

Yoke

1/4”-20

Bolt

Nyloc

™

Nut

Loading...

Loading...