General Information 28Service Manual – CS7000

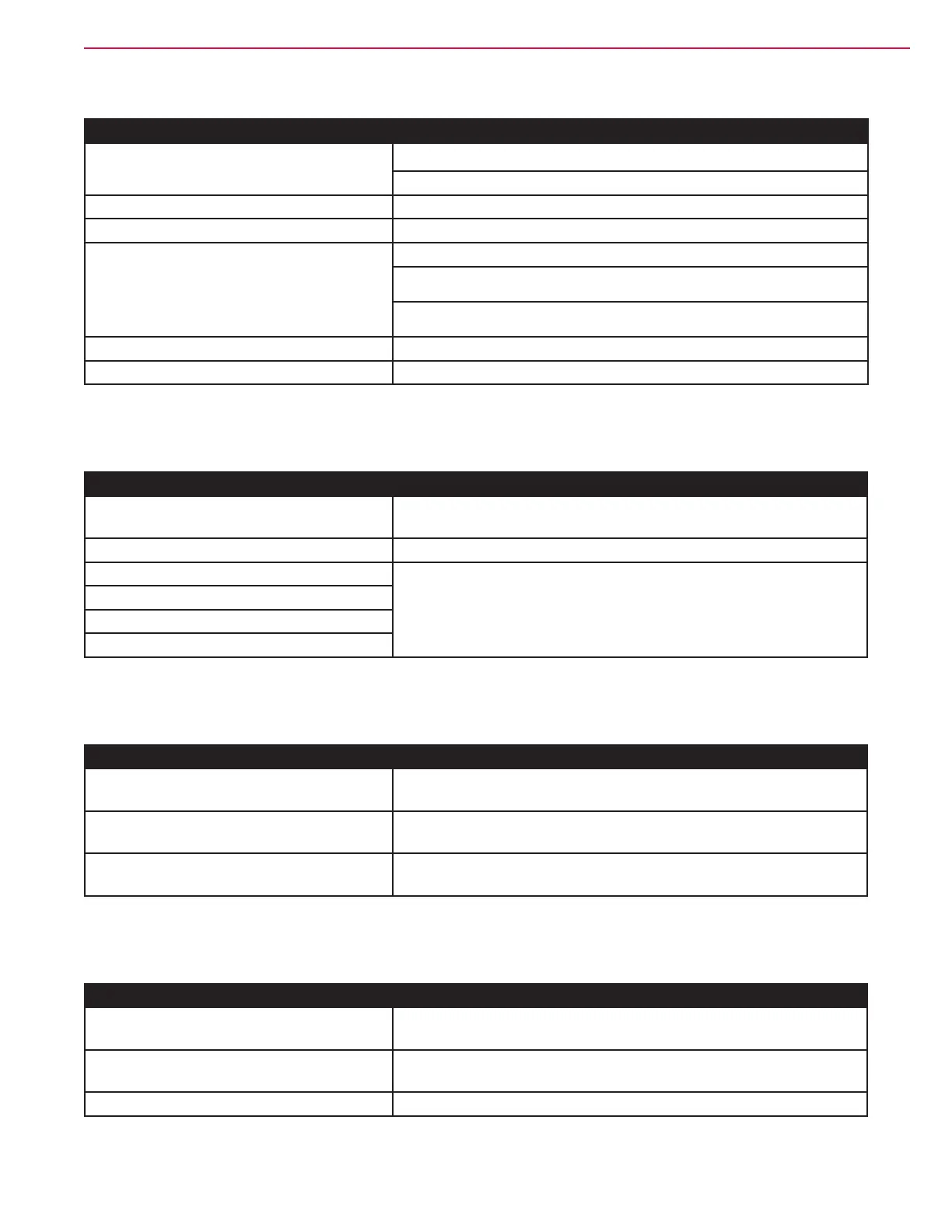

Maintenance Every 15 to 20 Hours

Maintenance Item Procedure

Battery/Batteries

Check the electrolyte level in the battery.

Check the battery cables and connections.

Solution tank lter Inspect and clean the debris lter on the solution lter system.

EcoFlex™ detergent system Purge the detergent delivery lines.

Sweep brooms

Rotate the main broom.

Inspect/adjust the main and side brooms.

Inspect the side broom housing skirts.

DustGuard

™

Clean the DustGuard

™

system spray nozzles.

Dust hopper Clean the hopper lter; inspect the hopper seals.

Monthly Maintenance

Maintenance Item Procedure

Squeegee caster wheel axle and pivot

Pump a small amount of grease into each grease tting on the

machine until grease seeps out around the bearings.

Steering gears Apply grease to lubricate.

Squeegee tool end wheels

Apply light machine oil to lubricate.

Engine/Battery compartment latch

Recovery tank latch

Brake Pedal (parking brake) linkage

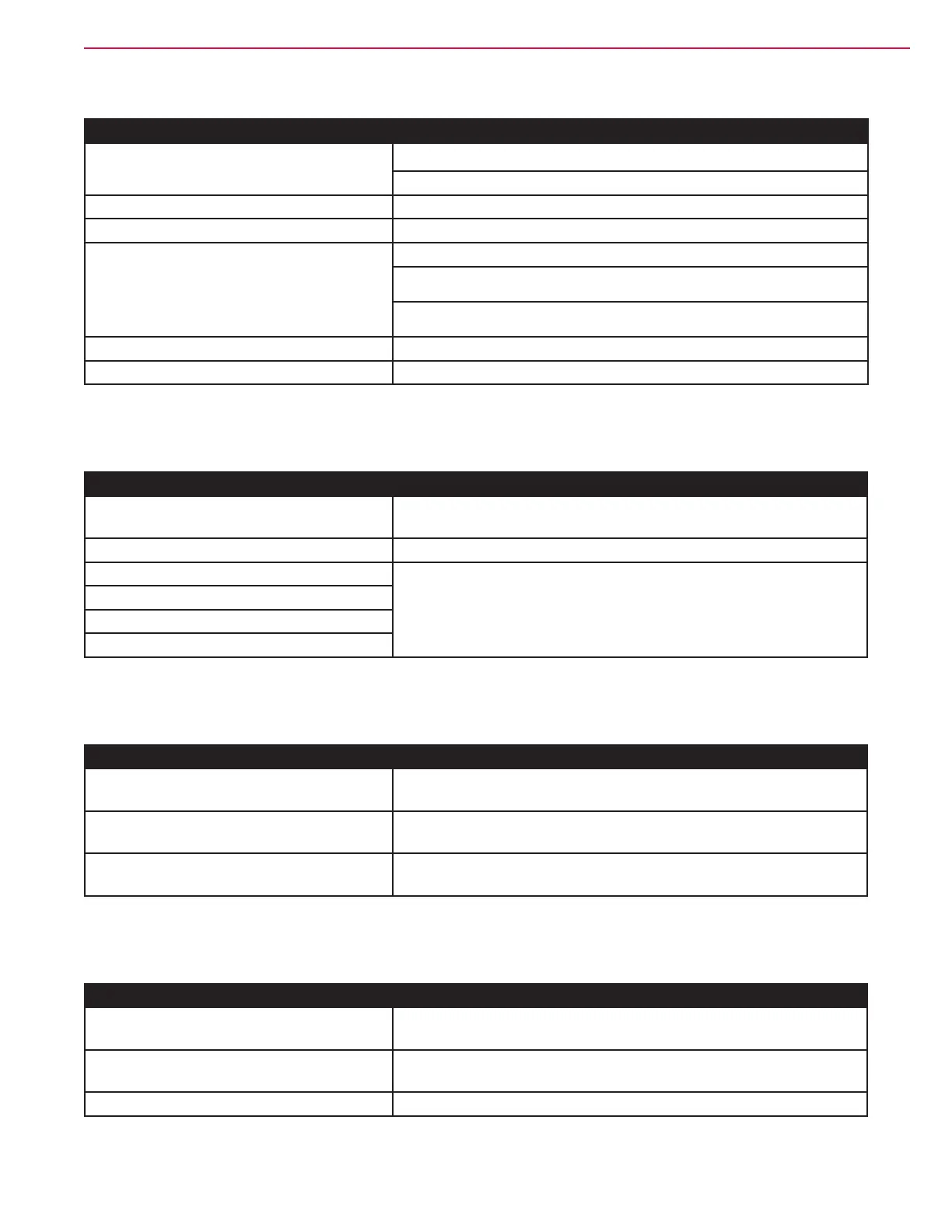

Maintenance Every 150 Hours

Maintenance Item Procedure

Engine maintenance (LPG and diesel

only)

Change the engine oil and oil lter. *Also review the engine

manufacturer’s additional maintenance requirements.

Radiator and oil cooler (LPG and diesel

only)

Inspect and clean the exterior core cooling ns.

LPG fuel system vaporizer/regulator –

LPG engines only

Inspect and drain any oil buildup from the LPG fuel vaporizer/

regulator.

Maintenance Every 400 Hours

Maintenance Item Procedure

Air intake housing and hoses (LPG and

diesel only)

Inspect the complete air intake system for correct routing, kinks,

restrictions, sound tight connections, holes and cracks in hoses.

Battery/Batteries

Check electrolyte level; check terminals for corrosion, loose

connections.

Fuel Filter (diesel only) Replace fuel lter cartridge (located before injector pump).

Loading...

Loading...