Hopper System 252Service Manual – CS7000

Hopper Hydraulic System Circuit Details

A hydraulic cylinder (ram), driven by a self-contained hydraulic pump and motor, raises and lowers the

hopper. The pump motor power and ground polarity are reversed to make the motor run in opposite

directions. Two contactors (K11 and K12) are used to operate the pump. Each contactor has two sets of

contacts; one that is closed when at rest (normally closed) and one that is open (normally open) when at rest.

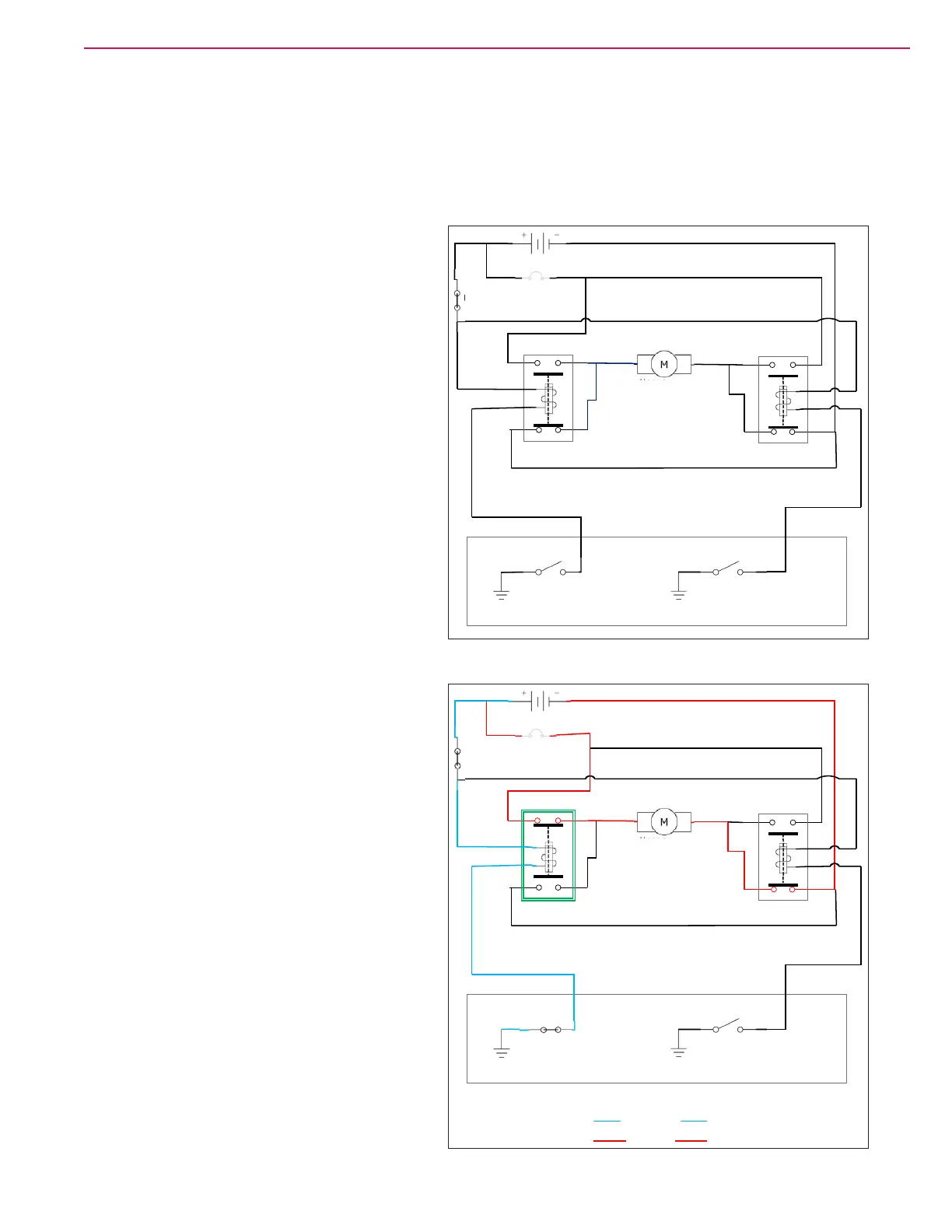

Hopper at Rest

When the hopper is “at rest”, the normally-

closed contacts of each contactor connect both

sides of the hopper hydraulic pump motor to

battery negative. Since there is no difference

in electrical pressure (voltage) across the

pump, no current ows and the pump remains

“Off”.

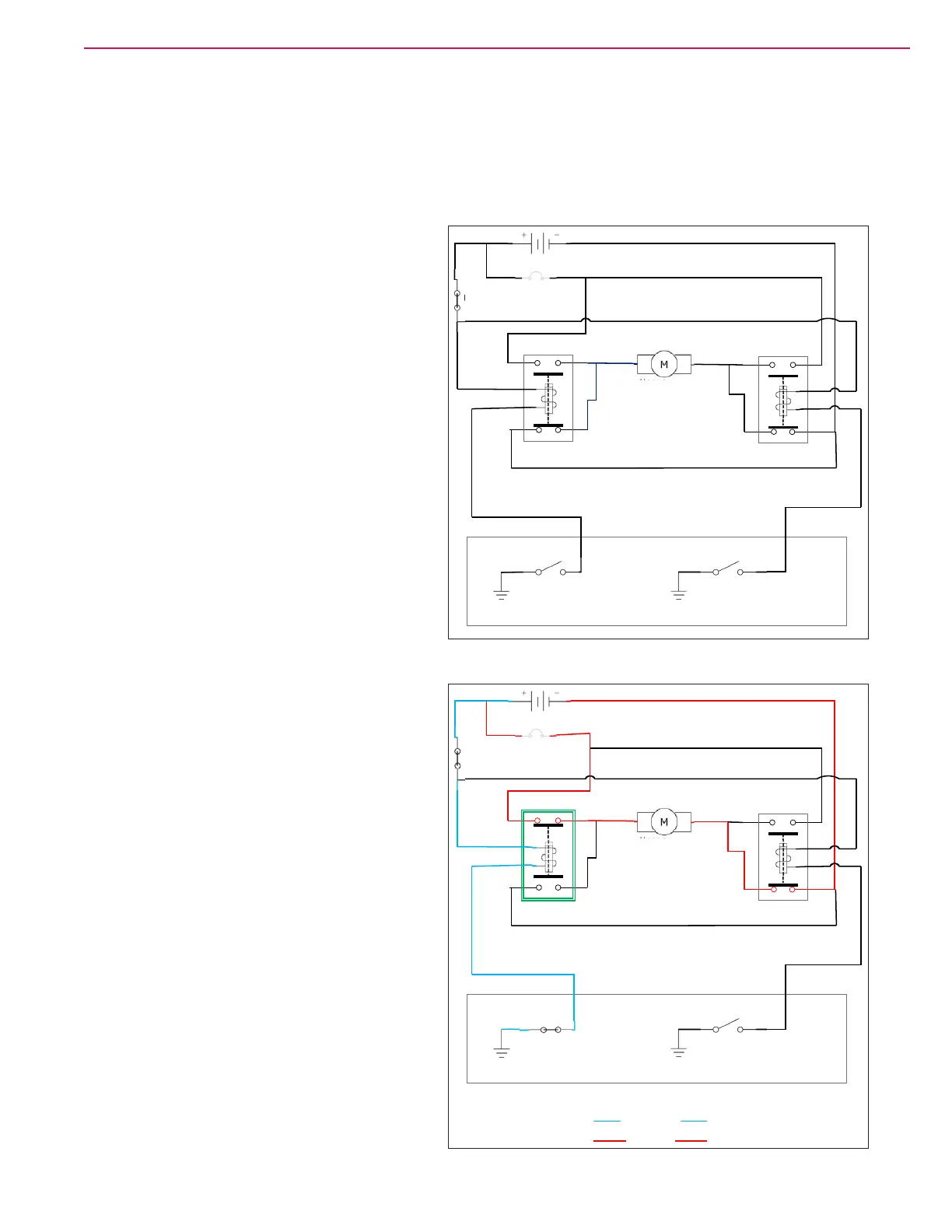

Hopper Being Raised

When the operator pushes the button to raise

the hopper, the main machine controller

energizes the K11 contactor by grounding the

control winding of the contactor. This causes

a magnetic eld to pull the normally-closed

contacts open, and at the same time closes

the normally-open contacts. Battery voltage

is now applied through the closed set of K11

contacts to one side of the pump. The other

side of the pump is connected to battery

negative through the normally-closed contacts

of the K12 contactor. This completes the

circuit and causes the pump to run in the “Up”

direction.

K11

At rest

K12

At rest

Hopper

Hydraulic

Pump Motor

Key switch

Main Machine Controller

K11

Energized

K12

At rest

Hopper

Hydraulic

Pump Motor

Key switch

Main Machine Controller

Control Circuit

Load Circuit

Hopper UP

Loading...

Loading...