Training Guide Course No. 196514

Level 2 Maintenance, X-1000 Series Dispensing Systems 4-91 P/N 196515 (Revision A)

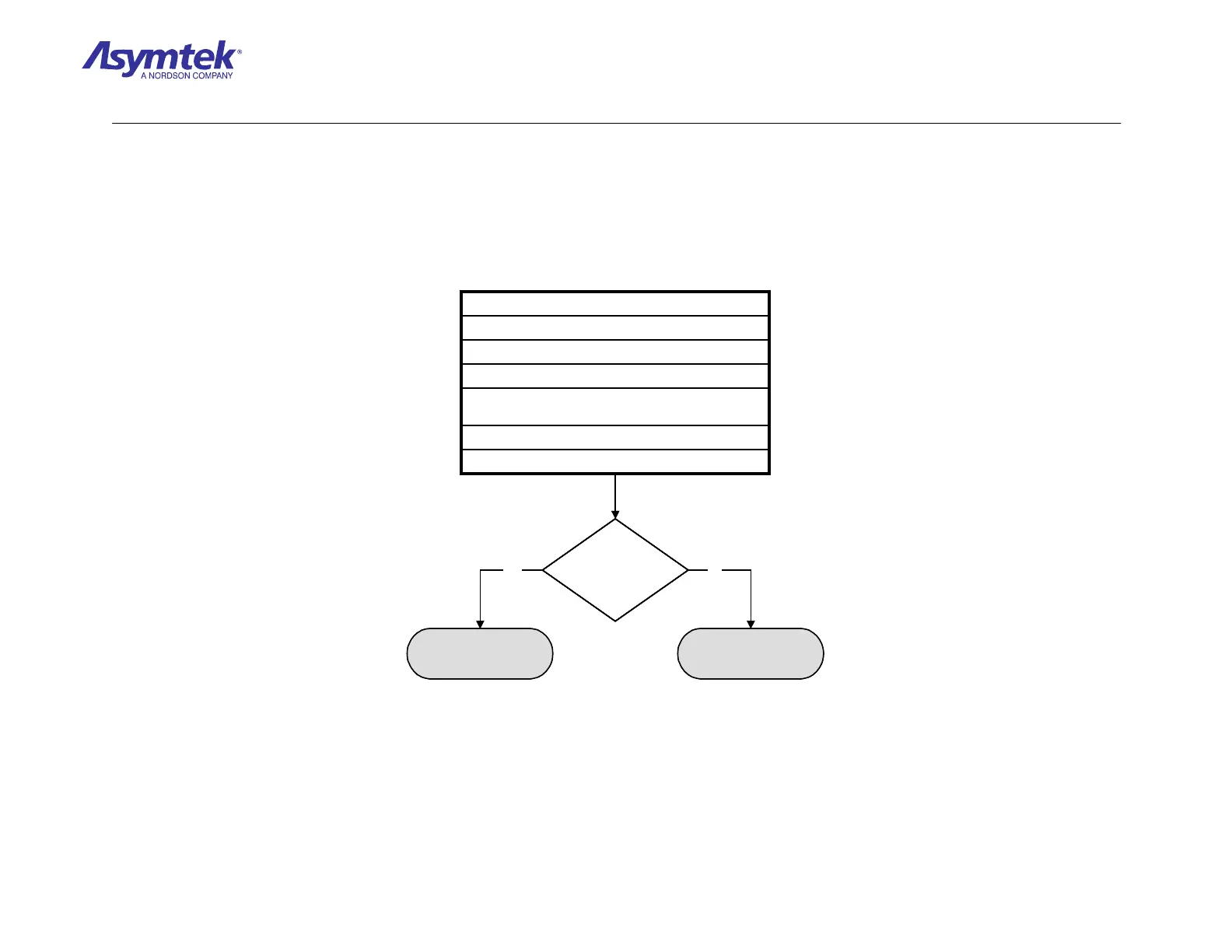

• Look for damaged electrical cables.

• Look for disconnected or poorly secured electrical cables.

• Look for obstructions that prevent Lift Tables and Stop Pins

to raise or lower.

• Look for pinched or obstructed pneumatic hoses.

• Look for cuts or disconnected pneumatic hoses.

• Listen for pneumatic leaks (a hissing sound).

Perform the following inspections:

Is mechanical

correction required as

a result of the above

inspections?

Resolve and go to Facility

Power and Air Supply

Verification

Go to Facility Power and

Air Supply Verification

NoYes

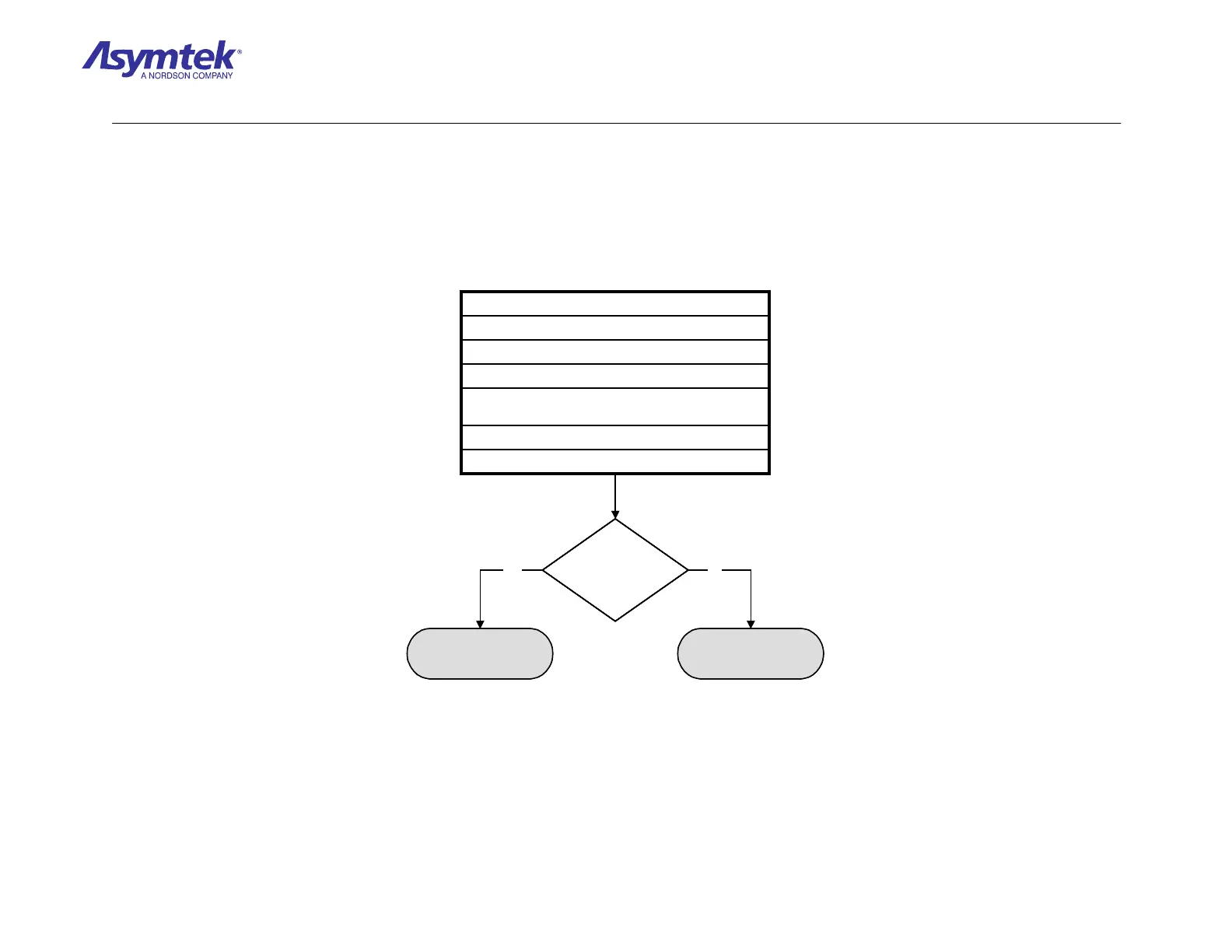

• Look for damaged electrical cables.

• Look for disconnected or poorly secured electrical cables.

• Look for obstructions that prevent Lift Tables and Stop Pins

to raise or lower.

• Look for pinched or obstructed pneumatic hoses.

• Look for cuts or disconnected pneumatic hoses.

• Listen for pneumatic leaks (a hissing sound).

Perform the following inspections:

• Look for damaged electrical cables.

• Look for disconnected or poorly secured electrical cables.

• Look for obstructions that prevent Lift Tables and Stop Pins

to raise or lower.

• Look for pinched or obstructed pneumatic hoses.

• Look for cuts or disconnected pneumatic hoses.

• Listen for pneumatic leaks (a hissing sound).

Perform the following inspections:

Is mechanical

correction required as

a result of the above

inspections?

Is mechanical

correction required as

a result of the above

inspections?

Resolve and go to Facility

Power and Air Supply

Verification

Go to Facility Power and

Air Supply Verification

NoYes

Diagram Sheet 4-7-1

Pneumatics Fault Isolation Procedure - Mechanical Verification

Loading...

Loading...