Training Guide Course No. 196514

Level 2 Maintenance, X-1000 Series Dispensing Systems 4-106 P/N 196515 (Revision A)

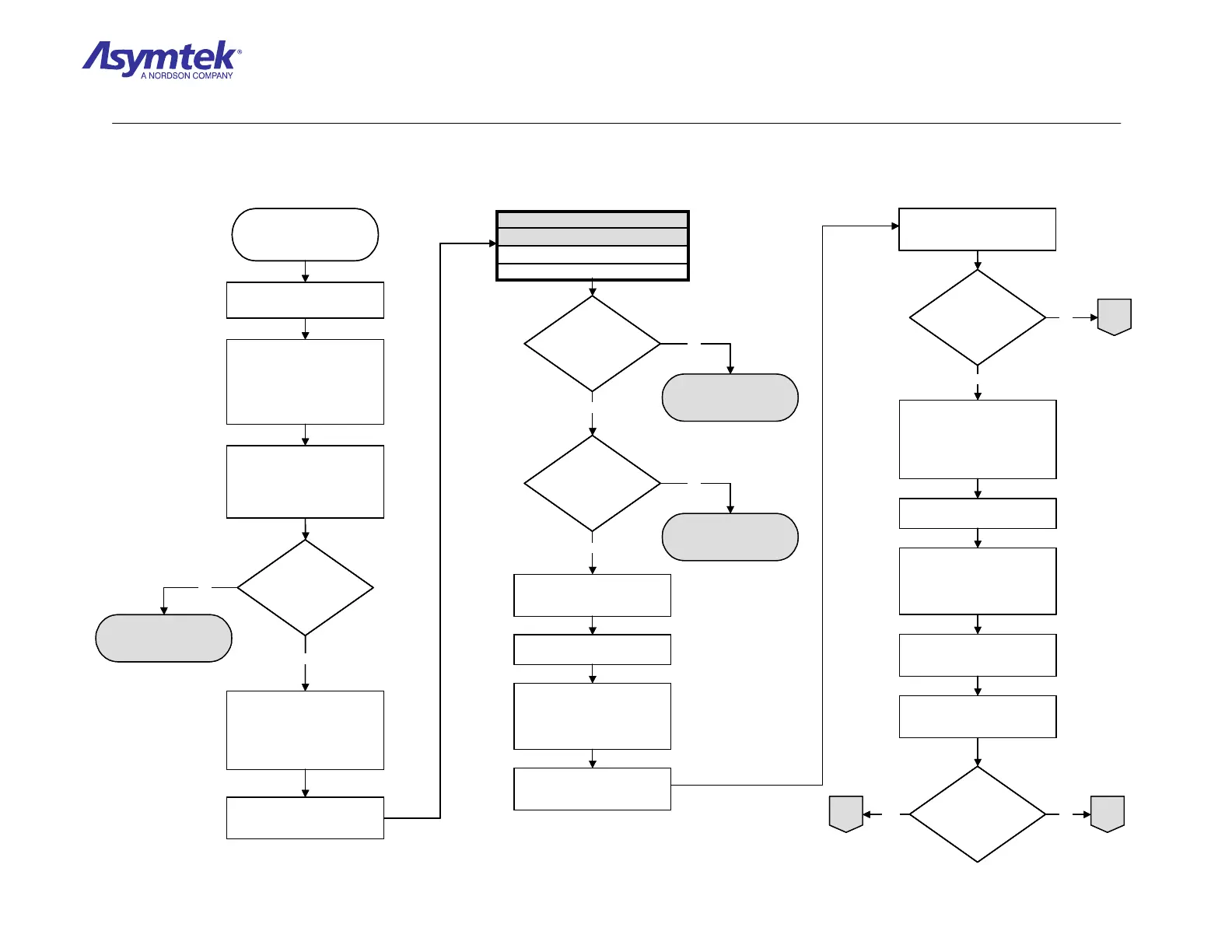

Exit FmNT, shut down

Windows NT and press the

black OFF (0) button on the

Operator’s Console

As Motors turn,

do the six LEDs

appear to illuminate

intermittently?

Remove the Conveyor

Controller Cover.

Connect the Power Cable to

the facility outlet, switch Main

Circuit Breaker to ON (I)

position, press the green ON

(I) button on the Operator’s

Console, and enter FmNT.

While jogging the Belt

Motors, observe the six LEDs

(labeled D32 to D36) located

in the middle of Conveyor

Controller Lower Board.

Exit FmNT, shut down Windows

NT, press black OFF (0) button

on the Operator’s Console,

switch Main Circuit Breaker to

OFF (0), and disconnect Power

Cable from facility outlet.

B

Conveyor Controller

(P/N 62-1677-00 on

X1020, or P/N 62-1676

on X1010) has failed

Check resistance between

connector pins on both Belt

Motors as specified in Table 1

Between Pin 3 and Pin 4

Between Pin 1 and Pin 2

CONNECTOR PINS

TABLE 1

Is resistance 1.5

ohms between pins on

the Front Belt Motor

Connector?

Is resistance 1.5

ohms between pins on

the Rear Belt Motor

Connector?

Disconnect the Width Motor

Connector from the Conveyor

Interconnect PWA.

Install Rear Belt Motor connector

in the Width Motor connector.

Connect the Power Cable to

facility outlet, switch Main Circuit

Breaker to ON (I), press green

ON (I) button on the Operator’s

Console, and enter FmNT.

From any FmNT window, click on

the Jog icon, or press [Ctrl + J]

on the Keyboard.

Click on Conveyor and use the

Jog Controls to change the

Conveyor width.

Did the Rear Belt

Motor turn?

Exit FmNT, shut down Windows

NT, press the black OFF (0)

button on the Operator’s Console,

switch Main Circuit Breaker to

OFF (0), and disconnect Power

Cable from the facility outlet.

Install Front Belt Motor connector

in the Width Motor receptacle.

Connect the Power Cable to the

facility outlet, switch Main Circuit

Breaker to ON (I), press the

green ON (I) button on Operator’s

Console, and enter FmNT.

From any FmNT window, click on

the Jog icon, or press [Ctrl + J]

on the Keyboard.

Click on Conveyor and use the

Jog Controls to change the

Conveyor width.

Did the Front Belt

Motor turn?

Front Belt Motor (P/N 07-

0716-00) has failed

Rear Belt Motor (P/N 07-

0716-00) has failed.

A

B

Yes

No

Yes

No

Yes

No

Yes

No

Yes No

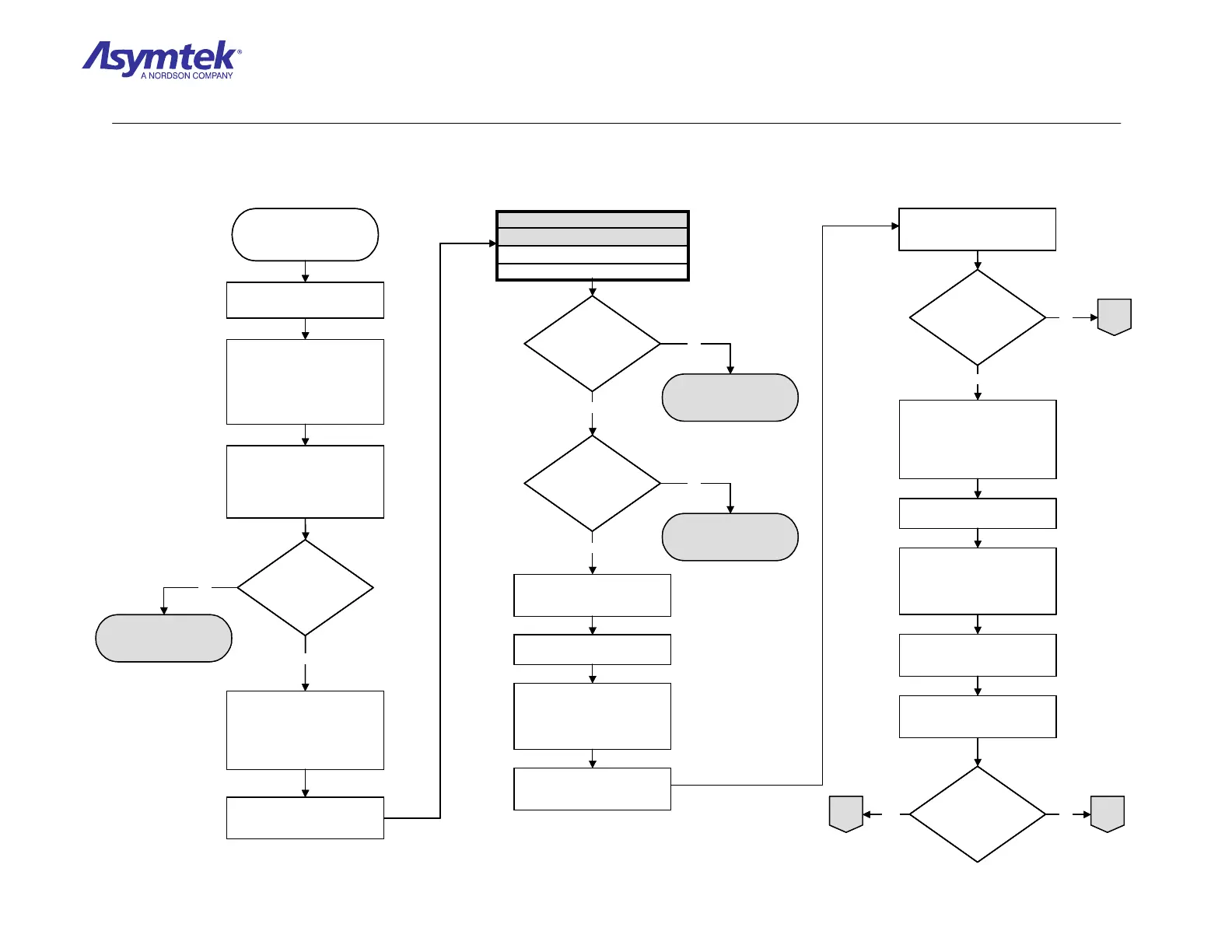

Exit FmNT, shut down

Windows NT and press the

black OFF (0) button on the

Operator’s Console

As Motors turn,

do the six LEDs

appear to illuminate

intermittently?

As Motors turn,

do the six LEDs

appear to illuminate

intermittently?

Remove the Conveyor

Controller Cover.

Connect the Power Cable to

the facility outlet, switch Main

Circuit Breaker to ON (I)

position, press the green ON

(I) button on the Operator’s

Console, and enter FmNT.

While jogging the Belt

Motors, observe the six LEDs

(labeled D32 to D36) located

in the middle of Conveyor

Controller Lower Board.

Exit FmNT, shut down Windows

NT, press black OFF (0) button

on the Operator’s Console,

switch Main Circuit Breaker to

OFF (0), and disconnect Power

Cable from facility outlet.

B

Conveyor Controller

(P/N 62-1677-00 on

X1020, or P/N 62-1676

on X1010) has failed

Check resistance between

connector pins on both Belt

Motors as specified in Table 1

Between Pin 3 and Pin 4

Between Pin 1 and Pin 2

CONNECTOR PINS

TABLE 1

Between Pin 3 and Pin 4

Between Pin 1 and Pin 2

CONNECTOR PINS

TABLE 1

Is resistance 1.5

ohms between pins on

the Front Belt Motor

Connector?

Is resistance 1.5

ohms between pins on

the Front Belt Motor

Connector?

Is resistance 1.5

ohms between pins on

the Rear Belt Motor

Connector?

Is resistance 1.5

ohms between pins on

the Rear Belt Motor

Connector?

Disconnect the Width Motor

Connector from the Conveyor

Interconnect PWA.

Install Rear Belt Motor connector

in the Width Motor connector.

Connect the Power Cable to

facility outlet, switch Main Circuit

Breaker to ON (I), press green

ON (I) button on the Operator’s

Console, and enter FmNT.

From any FmNT window, click on

the Jog icon, or press [Ctrl + J]

on the Keyboard.

Click on Conveyor and use the

Jog Controls to change the

Conveyor width.

Did the Rear Belt

Motor turn?

Did the Rear Belt

Motor turn?

Exit FmNT, shut down Windows

NT, press the black OFF (0)

button on the Operator’s Console,

switch Main Circuit Breaker to

OFF (0), and disconnect Power

Cable from the facility outlet.

Install Front Belt Motor connector

in the Width Motor receptacle.

Connect the Power Cable to the

facility outlet, switch Main Circuit

Breaker to ON (I), press the

green ON (I) button on Operator’s

Console, and enter FmNT.

From any FmNT window, click on

the Jog icon, or press [Ctrl + J]

on the Keyboard.

Click on Conveyor and use the

Jog Controls to change the

Conveyor width.

Did the Front Belt

Motor turn?

Did the Front Belt

Motor turn?

Front Belt Motor (P/N 07-

0716-00) has failed

Rear Belt Motor (P/N 07-

0716-00) has failed.

A

B

Yes

No

Yes

No

Yes

No

Yes

No

Yes No

Diagram Sheet 4-8-7

Conveyor Motors Fault Isolation Procedure – Rear/Front Belt Motor Verification

Loading...

Loading...