Training Guide Course No. 196514

Level 2 Maintenance, X-1000 Series Dispensing Systems 4-117 P/N 196515 (Revision A)

A

8ShieldShell

3Purple9

9Yellow8

11Orange7

4Blue6

12Brown5

2Green4

10Red3

1White2

N/CBlack1

P2ColorP1

TABLE 2

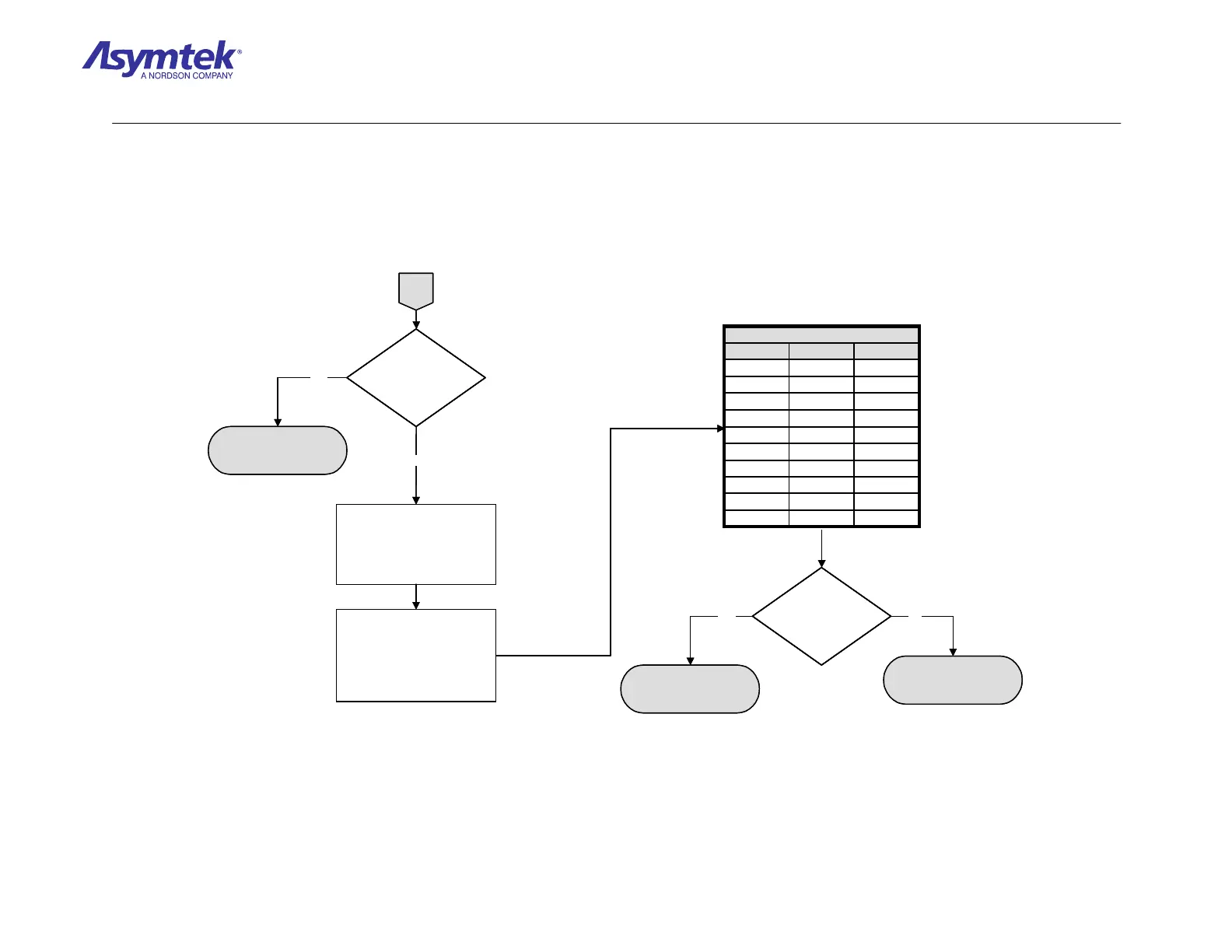

IS ON displayed?

Exit FmNT, shut down Windows

NT, press black OFF (0) button

on the Operator’s Console,

switch Main Circuit Breaker to

OFF (0), and disconnect Power

Cable from facility outlet.

Verify continuity of P/N 06-4644-

00 SMEMA Downstream Cable,

routed between Conveyor

Controller and Rear Bulkhead of

dispensing system. Pin

connections are specified in

Table 2.

External SMEMA

Downstream Cable (P/N

06-2141-00) has failed

Yes

No

Is there continuity?

SMEMA Downstream

Cable (P/N 06-4644-00)

has failed.

Conveyor Controller

(P/N 62-1677-00 on

X1020, or P/N 62-1676 on

X1010) has failed.

Yes No

A

8ShieldShell

3Purple9

9Yellow8

11Orange7

4Blue6

12Brown5

2Green4

10Red3

1White2

N/CBlack1

P2ColorP1

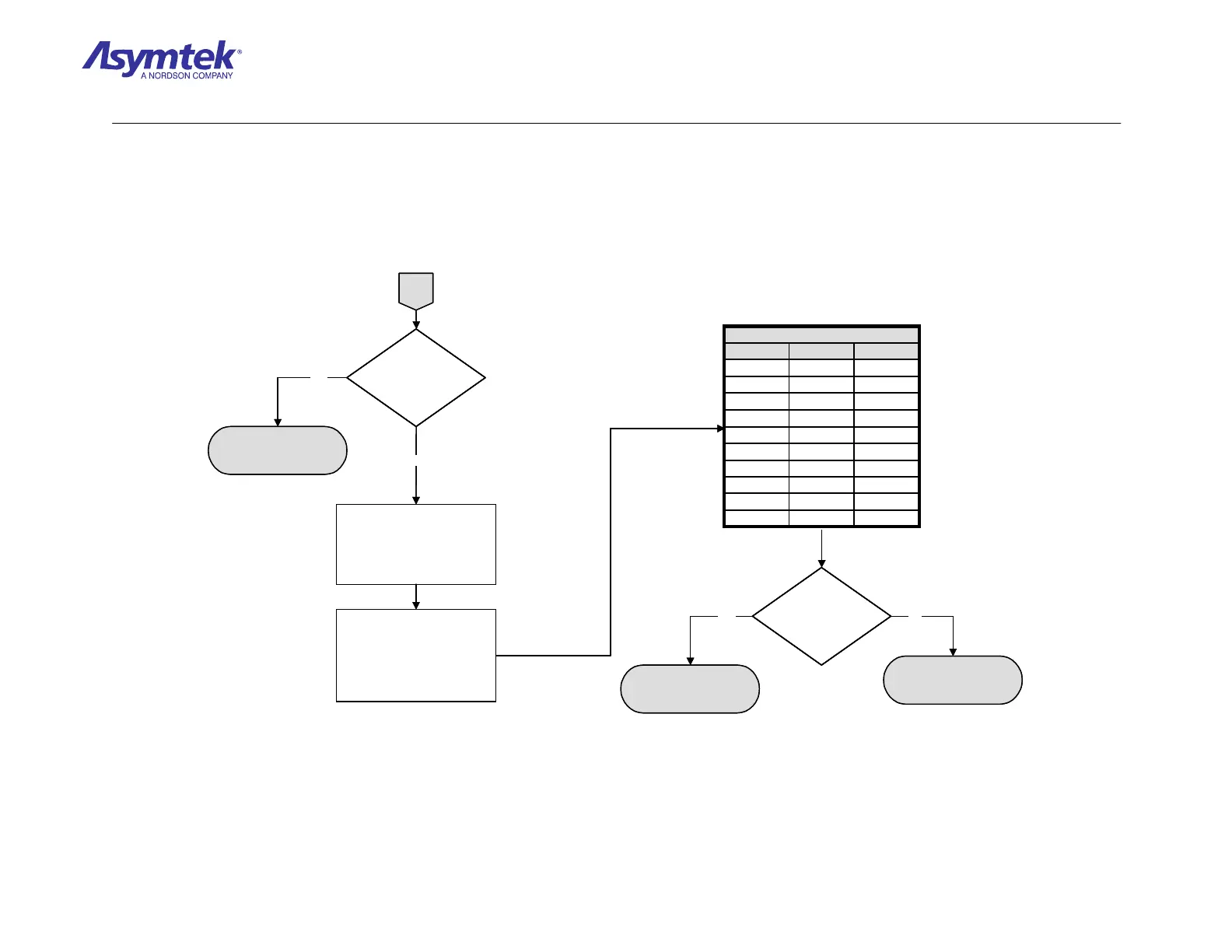

TABLE 2

8ShieldShell

3Purple9

9Yellow8

11Orange7

4Blue6

12Brown5

2Green4

10Red3

1White2

N/CBlack1

P2ColorP1

TABLE 2

IS ON displayed?IS ON displayed?

Exit FmNT, shut down Windows

NT, press black OFF (0) button

on the Operator’s Console,

switch Main Circuit Breaker to

OFF (0), and disconnect Power

Cable from facility outlet.

Verify continuity of P/N 06-4644-

00 SMEMA Downstream Cable,

routed between Conveyor

Controller and Rear Bulkhead of

dispensing system. Pin

connections are specified in

Table 2.

External SMEMA

Downstream Cable (P/N

06-2141-00) has failed

Yes

No

Is there continuity?Is there continuity?

SMEMA Downstream

Cable (P/N 06-4644-00)

has failed.

Conveyor Controller

(P/N 62-1677-00 on

X1020, or P/N 62-1676 on

X1010) has failed.

Yes No

Diagram Sheet 4-8-18

SMEMA Fault Isolation Procedure – Downstream Workpiece Transfer Verification (Continued)

Loading...

Loading...