Training Guide Course No. 196514

Level 2 Maintenance, X-1000 Series Dispensing Systems 4-149 P/N 196515 (Revision A)

Information Sheet 4-13-4

DV-7000 Troubleshooting

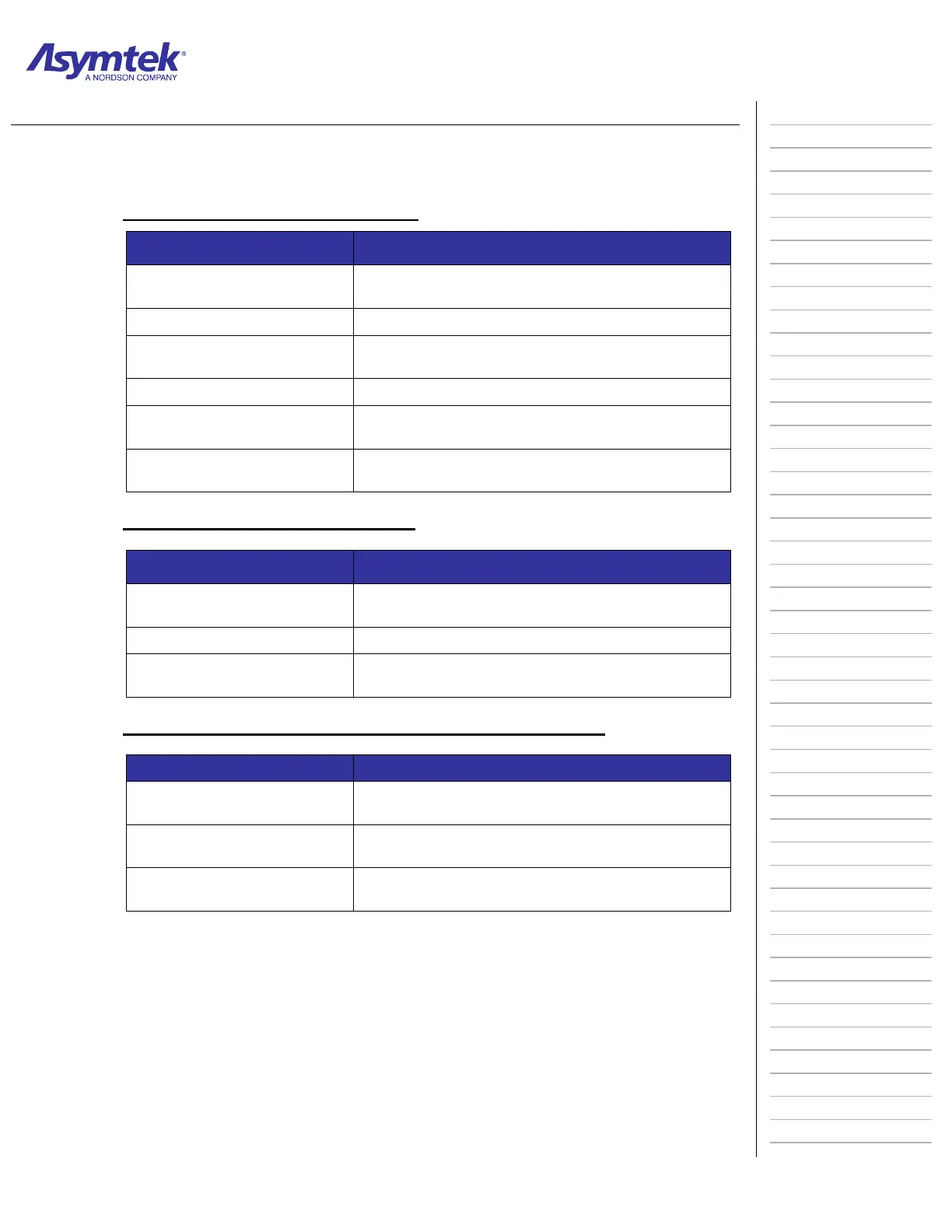

A. Intermittent Or No Fluid Dispensing

Possible Cause Recovery

Pump poorly primed

See “Priming the DV-7000” in the Valve Operations

Manual.

Clogged needle

Clean or replace the needle.

Plugged pump

Clean pump. See “Cleaning the DV-7000” in the

Valve Operations Manual.

Speed Control set to 0 rpm See “Adjustments” in the Valve Operations Manual.

No power to motor

Make sure that the valve power cord is connected to

the power outlet on the dispensing head.

Fluid syringe is empty

See “Changing the Syringe” in the Valve Operations

Manual.

B. Needle Repeatedly Clogs With Fluid

Possible Cause Recovery

Fluid particles too big for

needle size

Replace needle with a bigger needle.

Needle bent or damaged Replace needle.

Fluid has exceeded pot life

or fill has separated

See “Changing the Syringe” in Valve Operations

Manual.

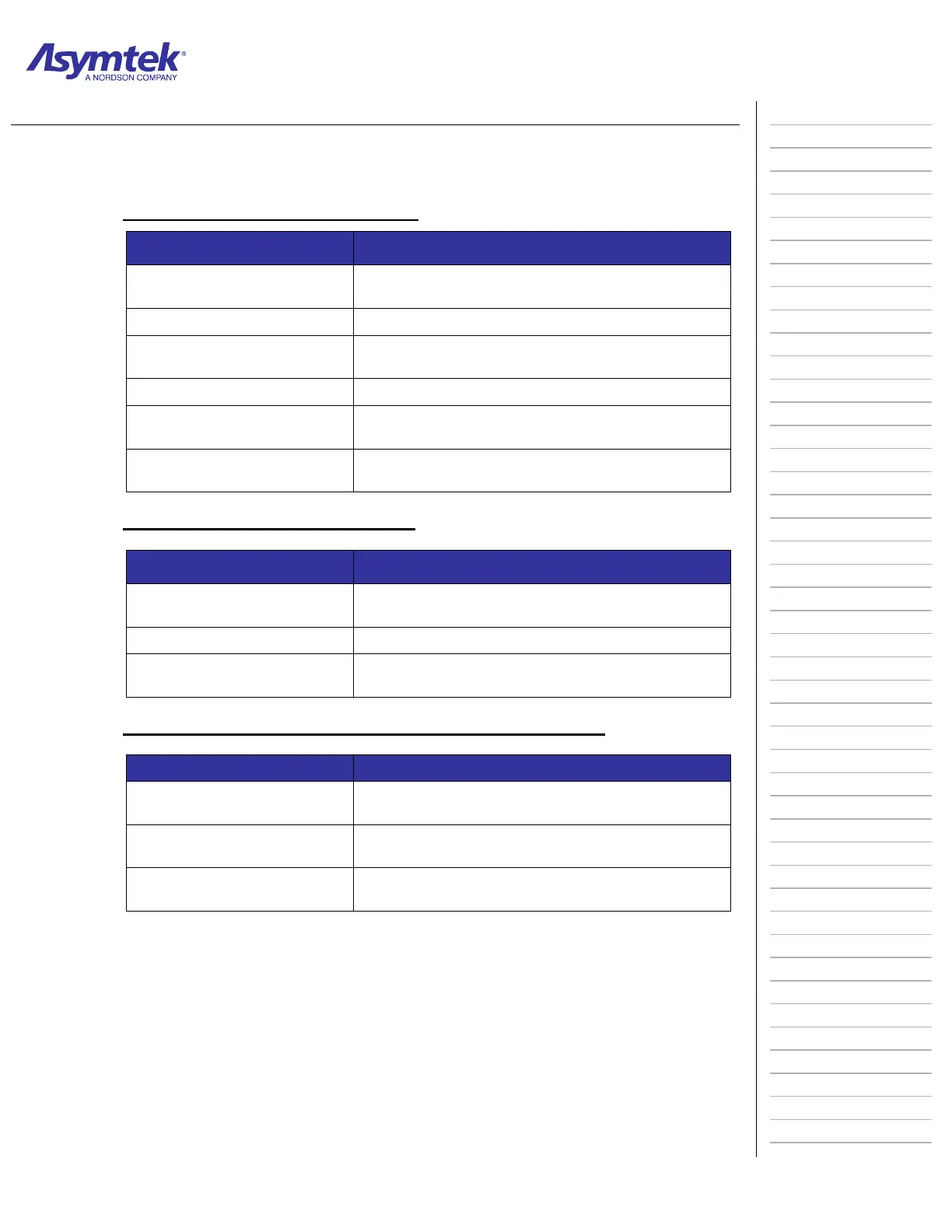

C. Material Drips Or Drools Continuously From Dispensing Tip

Possible Cause Recovery

Pump poorly primed

See “Priming the DV-7000” in the Valve Operations

Manual.

Wrong type of stopper in

syringe

Use zero draft (orange or yellow) stoppers in the

syringe.

Air inside syringe expands

Add a short Reverse Motor command to the end of

the dispensing command.

Loading...

Loading...