Training Guide Course No. 196514

Level 2 Maintenance, X-1000 Series Dispensing Systems 4-151 P/N 196515 (Revision A)

Information Sheet 4-13-6

DJ-2000 Troubleshooting

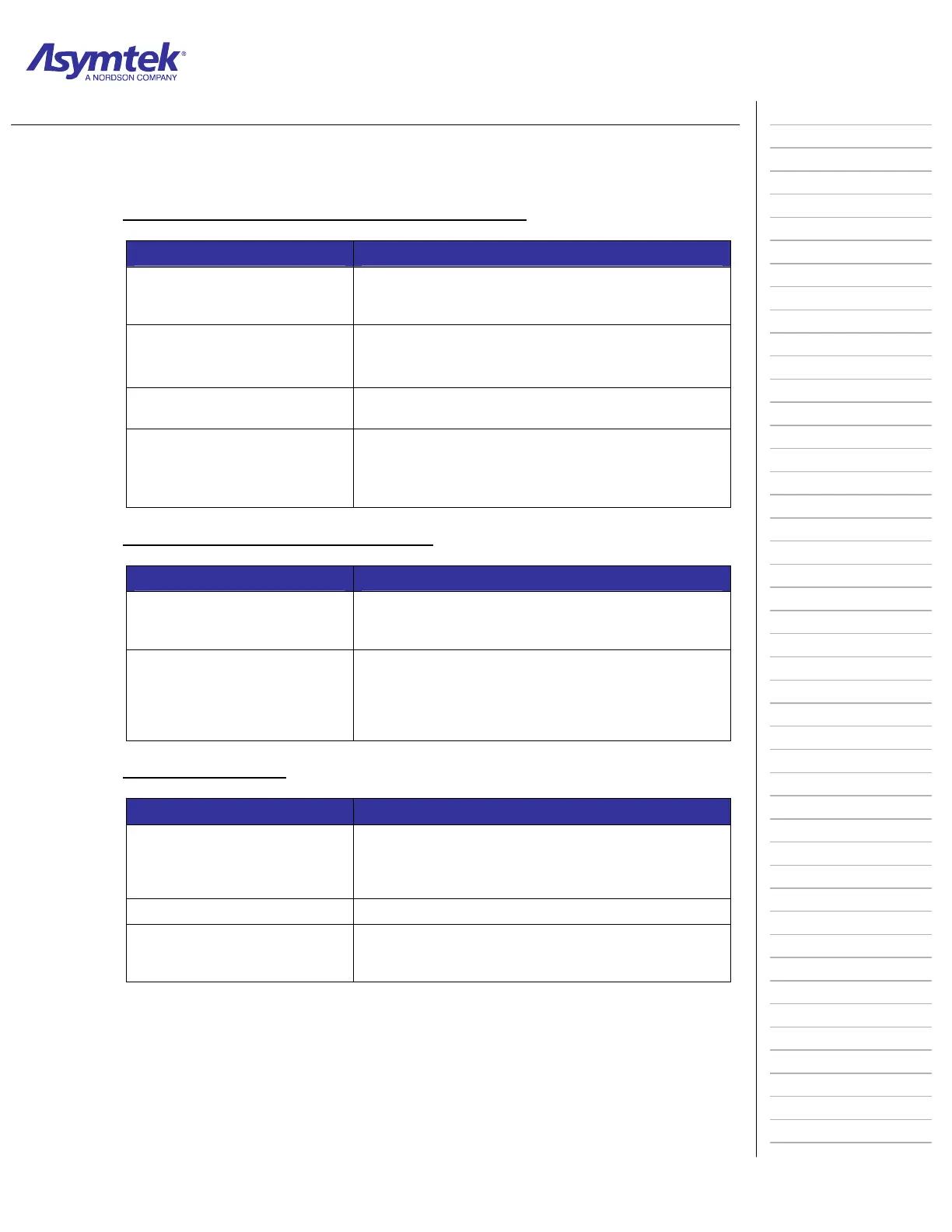

A. Nozzle Is Capping Over (tip is covered with fluid)

Possible Cause Recovery

Heat setting is too low

Raise the temperature. Refer to Section 4 – Heater

Control for Windows (HCW) of the Fluidmove for

Windows Installation and User Guide.

Incorrect Micrometer or

Preload settings

Adjust the Micrometer and/or Preload screw.

Inadequate purge routine

Increase purge time. Refer to DJ-2000 Operations

Manual.

Fluid continuously oozing

from the nozzle

Incorrect offset of the air piston to jet body. Refer to

“Adjusting the Air Piston” DJ-2000 Operations

Manual.

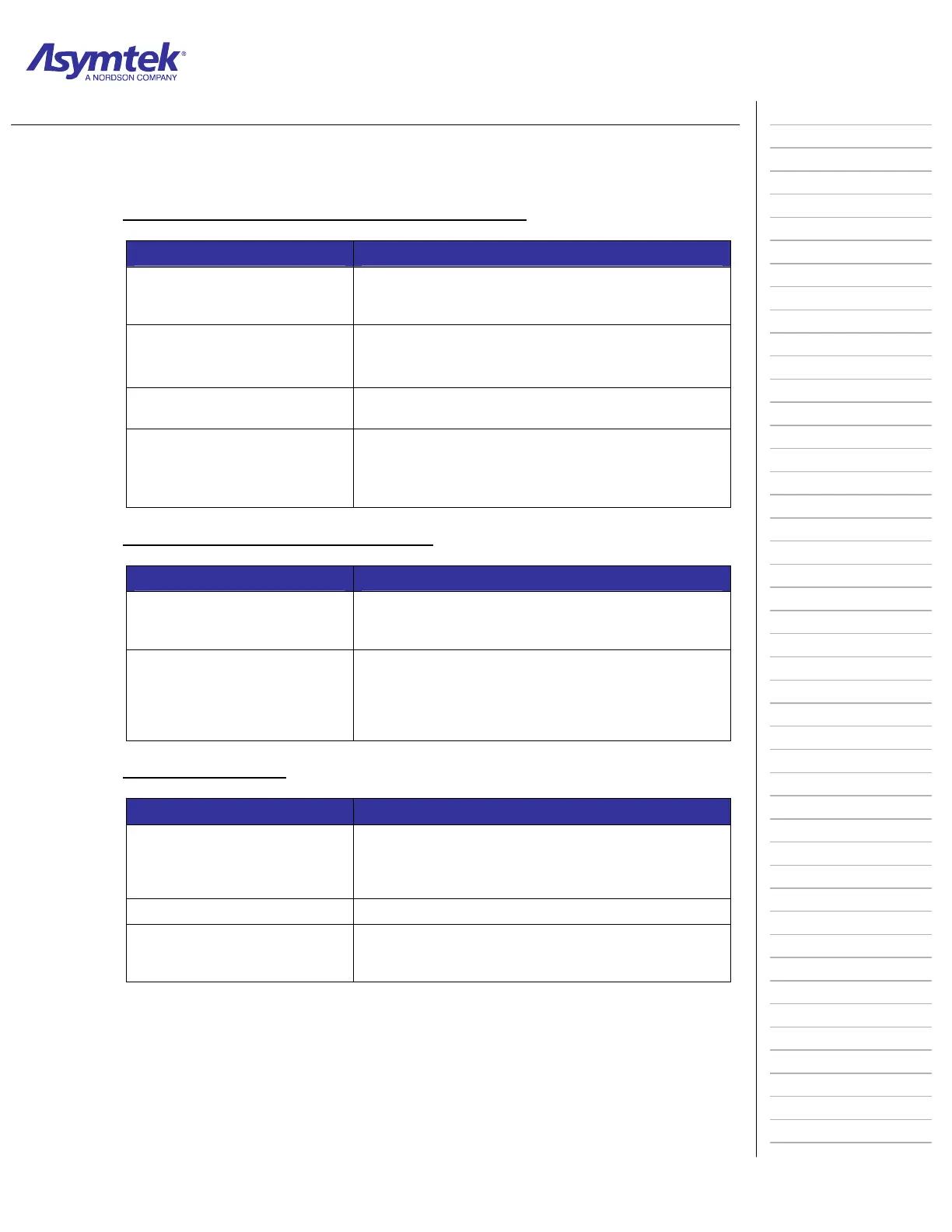

B. Tear Shaped Dots Or Poor Dot Quality

Possible Cause Recovery

Heat setting is too low

Raise the temperature. Refer to Section 4 – Heater

Control for Windows (HCW) of the Fluidmove for

Windows Installation and User Guide.

Incorrect Micrometer or

Preload settings; Preload

screw may not be tight

enough

Adjust the Micrometer and/or Preload screw.

C. Dots Are Not Round

Possible Cause Recovery

Dirty nozzle

Clean the nozzle with solvent and cleaning wire

(provided in DJ-2000 Spare Parts Kit). Refer to

nozzle cleaning procedure in Valve Operations

Manual.

Damaged nozzle Replace the nozzle.

Incorrect temperature

Set the correct temperature. Refer to Section 4 –

Heater Control for Windows (HCW) of the Fluidmove

for Windows Installation and User Guide.

Loading...

Loading...