4 - 35

4 Configuration and Wiring

AC Servomotors/Servo Drives 1S-series with Built-in EtherCAT® Communications User’s Manual (I586)

4-2 Wiring

4

4-2-2 Procedure for Wiring Terminal Block and Procedure for Mounting Shield Clamp to Servo Drive

• R88D-1SN15H-ECT/-1SN20H-ECT/-1SN30H-ECT/-1SN06F-ECT/-1SN10F-ECT/

-1SN15F-ECT/-1SN20F-ECT/-1SN30F-ECT

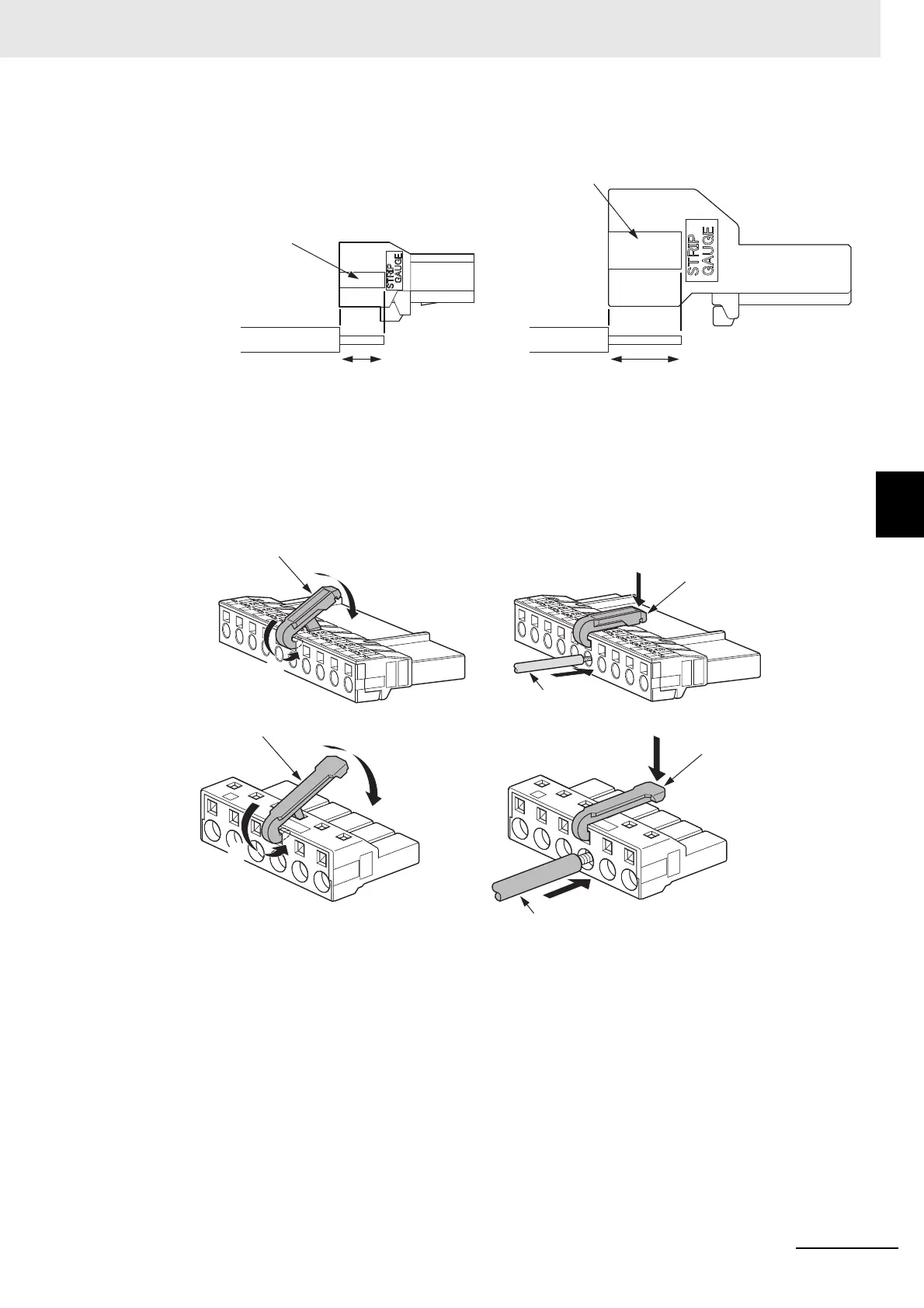

3 Connect the wires.

Insert the hook of the spring opener into a square hole located on the same side as the wire

holes, and use your thumb to press down the lever of the spring opener until it clicks into place.

Insert the wire fully into the back of a wire hole while the lever of the spring opener is held down.

Release the lever, and then pull the wire gently to check that it does not come out.

4 Mount the terminal block to the Servo Drive.

After all of the terminals are wired, return the terminal block to its original position on the Servo

Drive.

Note The wire may not be inserted easily depending on the shape of the ferrule connected to it. If this occurs,

perform one of the following methods to insert the wire.

• Change the direction of inserting the ferrule by 90°.

• Correct the shape of the ferrule with tools such as pliers.

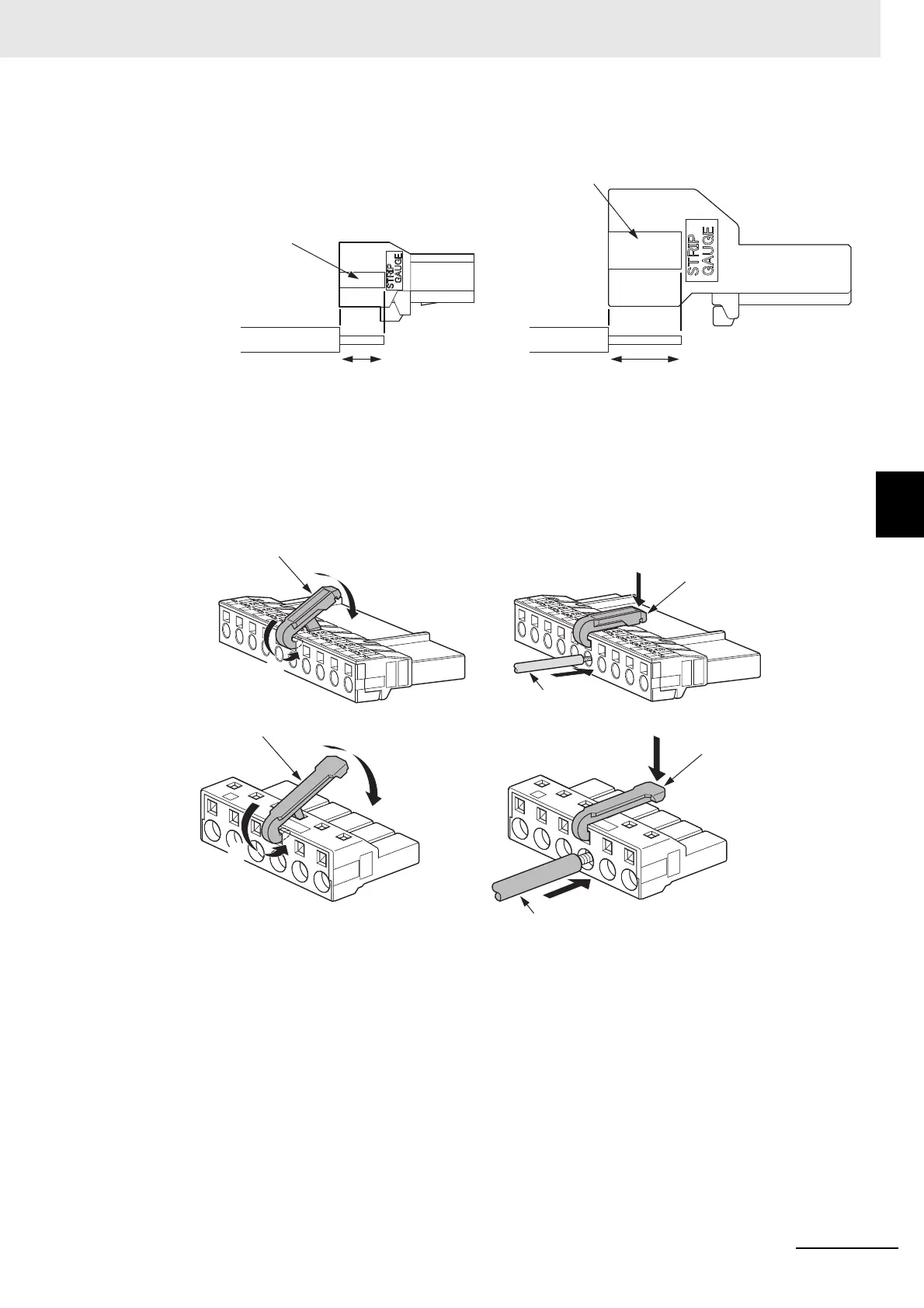

STRIP GAUGE

STRIP GAUGE

Wire Wire

Strip length

8.5±0.5mm

Strip length

13.7±0.5mm

(CND) (CNA/CNB/CNC)

10

9

8

7

6

5

4

3

2

1

10

9

8

7

6

5

4

3

2

1

1

1

2

Spring opener

Wire

Spring opener

2

Spring opener

Spring opener

Wire

1

Loading...

Loading...