26 Rockwell Automation Publication KNX-SG001H-EN-P - December 2020

Product Features Comparison

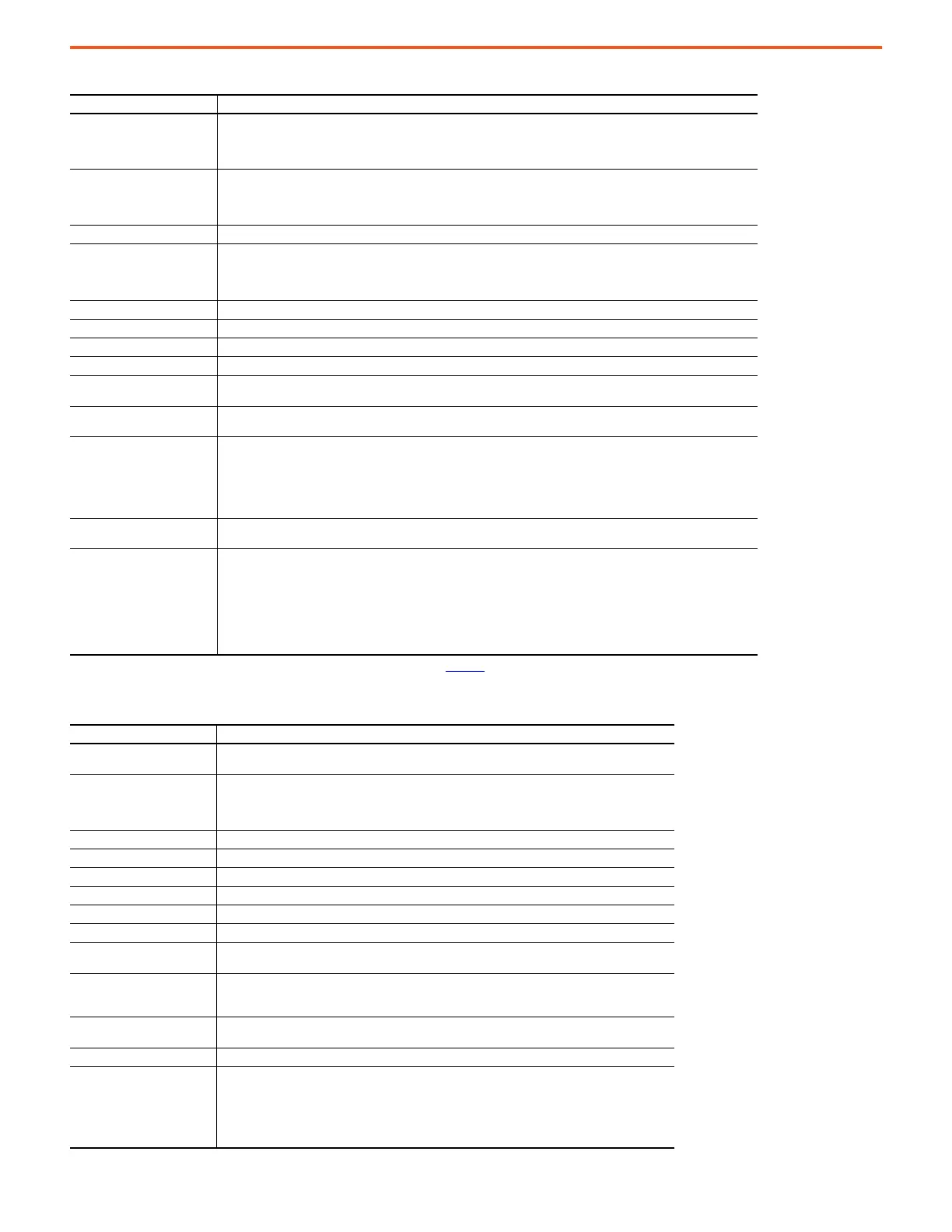

Kinetix TL and TLY Compact Servo Motors

Kinetix HPK Asynchronous Servo Motors

Motor Features Kinetix TL and TLY Servo Motors

Main characteristics

• Compact size, high torque density

• Metric and NEMA frame sizes

• Smart Motor Technology

• Low rotor inertia

Features

•230V windings

• High-energy (rare-earth) magnets

• Cable extensions, 1 m (3.2 ft)

• 17-bit serial communication

Motor type Brushless AC synchronous servo motors

Environmental rating

• IP54 without shaft seal (standard) and with the use of Rockwell Automation factory-delivered 2090-Series cable connectors

(excludes on-motor cable connectors).

• IP65 with optional shaft seal and with the use of Rockwell Automation factory-delivered 2090-Series cable connectors

(excludes on-motor cable connectors)

Continuous torque 0.086…5.42 N•m (0.76…48 lb•in)

Peak torque 0.22…13 N•m (1.94…115 lb•in)

Speed 4500, 5000, and 6000 rpm

Motor rated output 0.037…2.0 kW

Feedback options

• Multi-turn, (battery-backed) high-resolution absolute position

• Incremental (2000 counts)

Motor options

•24V DC brake

•Shaft seal kit

Compatible drives

(1)

(1) For Kinetix 2000 and Kinetix 3 drive specifications, refer to Additional Resources on page 233 for links to the applicable technical data and design guide

publications.

• Kinetix 5100 (Kinetix TL/TLY)

• Kinetix 5300 (Kinetix TL/TLY)

• Kinetix 6000 (Kinetix TLY)

• Kinetix 300/350 (Kinetix TLY)

• Kinetix 2000 (Kinetix TLY)

•Kinetix 3 (Kinetix TL)

Servo cable compatibility

• 2090-CxxM6xx cables (Kinetix TLY)

• 2090-DANxxx cables (Kinetix TL)

Typical applications

•Robotics

• Material handling

•X-Y tables

• Specialty machinery

• Semiconductor manufacturing

• Medical/laboratory equipment

• Light packaging machines

• Office machinery

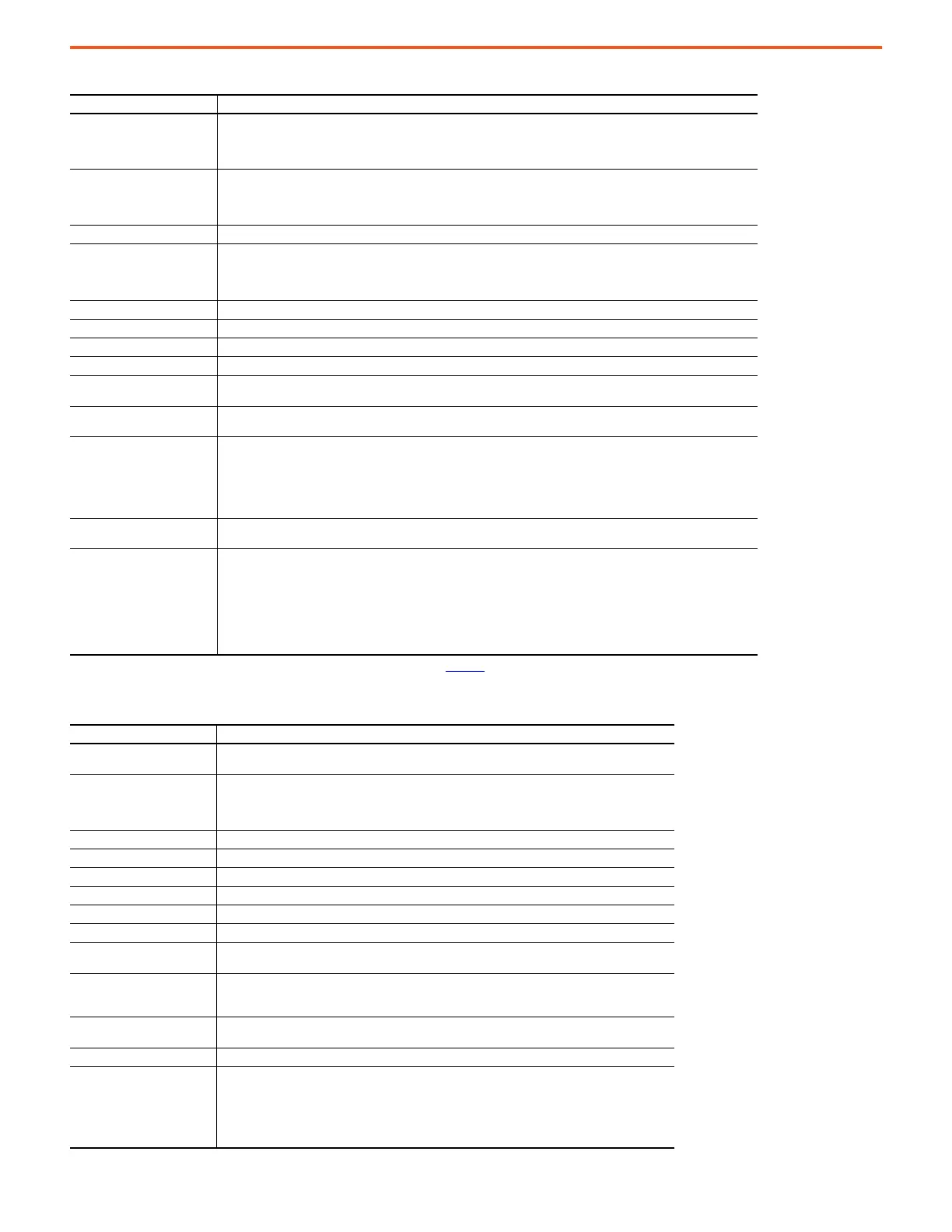

Motor Features Kinetix HPK Asynchronous Servo Motors

Main characteristics

•High-power

• Large load inertia

Features

• 400V and 460V windings

• DIN connectors, rotates 180°

•Blower cooled

• IEC flange or foot mount

Motor type Asynchronous Induction Motors

Environmental rating IP65 with the use of Rockwell Automation factory-delivered 2090-Series feedback cable connector.

Continuous torque 96…955 N•m (849…8452 lb•in)

Peak torque 165…1927 N•m (1460…17,054 lb•in)

Speed Base speeds of 1500 and 3000 rpm

Motor rated output 17.1…150 kW

Feedback options

• Multi-turn, high-resolution absolute position

• Single-turn, high-resolution absolute position

Motor options

• Multiple junction box mounting locations

• Holding brake, 380…460V

•HPK-xxxxxx-ENC-xx encoder kit

Compatible drives

•Kinetix 5700

•Kinetix 7000

Servo cable compatibility 2090-CFBM7Dx motor feedback cables

Typical applications

• High power packaging

•Converting

• Wind/unwind/rewind

•Sheeters

• Flying knife

• Material handling

Loading...

Loading...