34 Rockwell Automation Publication KNX-SG001H-EN-P - December 2020

Product Features Comparison

Motor and Actuator Cables

Cables meet CE compliance and are UL Listed or Recognized components to applicable U.S. and Canadian safety standards. Refer to

http://ab.rockwellautomation.com

for more information.

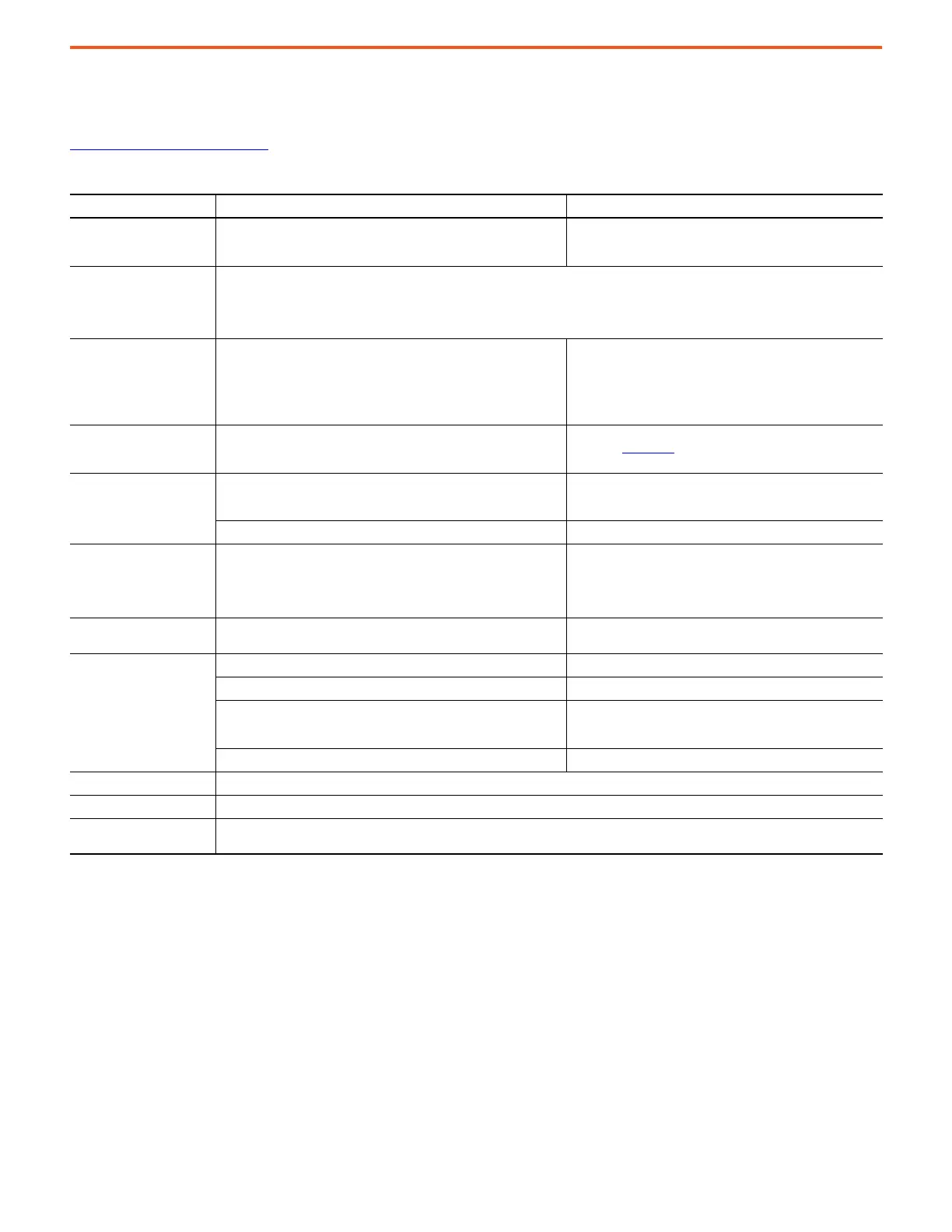

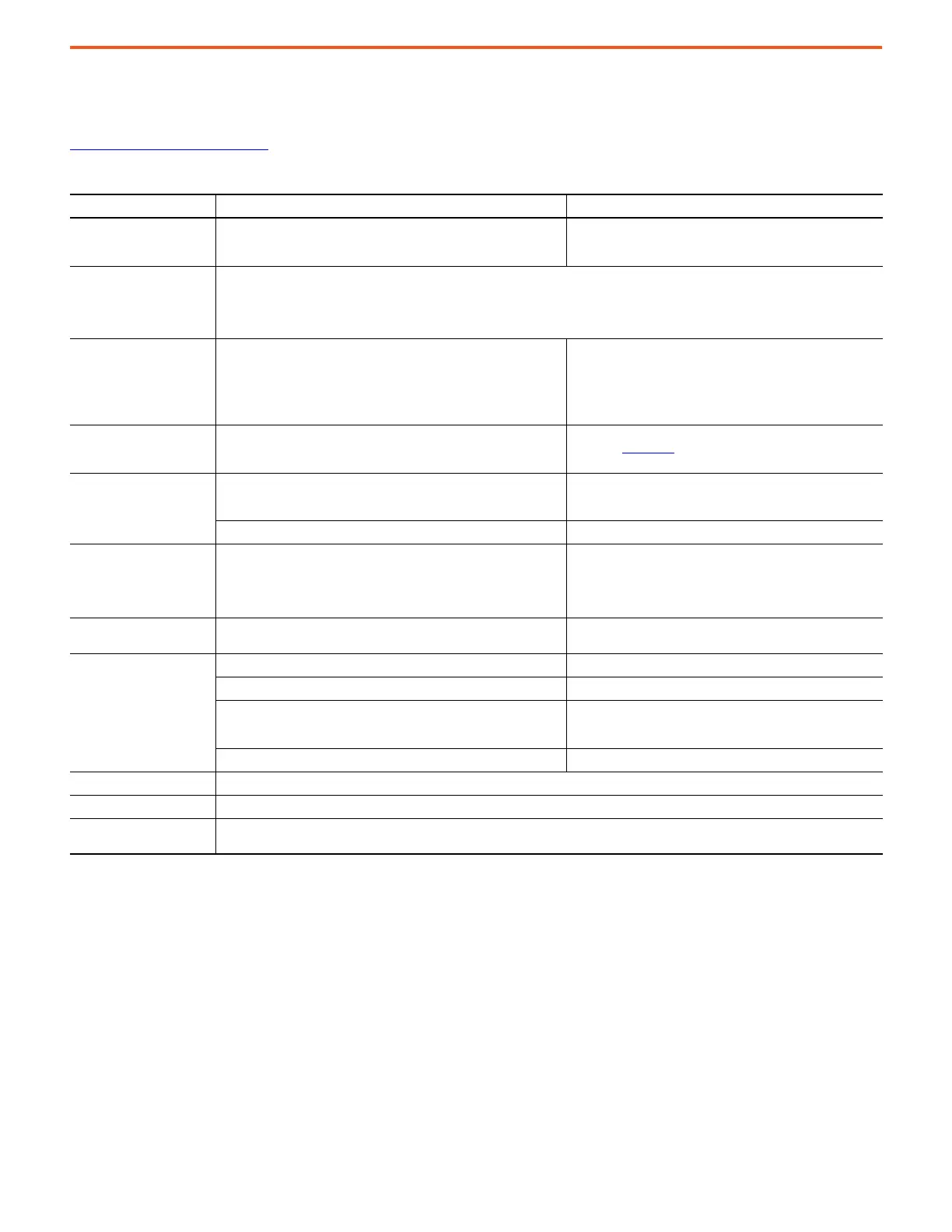

Single Motor Cables

Cable Features TPE Single Motor Cables PVC and Halogen-free PUR Single Motor Cables

Catalog numbers

•2090-CSxM1Dx-xxAAxx standard, non-flex cables

•2090-CSBM1Dx-xxAFxx continuous-flex cables

• 2090-CSBM1E1-xxAFxx continuous-flex extension cables

• 2090-CSxM1Dx-xxVAxx (PVC) standard, non-flex cables

• 2090-CSBM1Dx-xxLFxx (PUR) continuous-flex cables

• 2090-CSBM1E1-xxVA/LFxx (PVC/PUR) extension cables

Common features

• Designed in accordance with NFPA-79

• Low capacitance design to maximize system power density

• SpeedTec connection system

• Encoder communication data pair with state of the art noise rejection

• DESINA compliant jacket (orange) coloring for easy identification and separation of cables in a machine

Agency compliance

• UL Listed

– 10, 8, and 6 AWG bulk cable, flexible VFD servo cable

– PLTC-ER rated bulk cable (14 and 18 AWG)

– UL AWM, 1000V, 105 °C construction

– cUR AWM I/II A/B, 600V, 105 °C construction for 6 and 8 AWG cables

• CSA AWM I/II A/B, 1000V, 105 °C construction for 10, 14, and 18 AWG cables

• UL Recognized

– 18, 14, 10, 8, and 6 AWG bulk cable

– UL AWM, 1000V, 90 °C construction

– cUR AWM I/II A/B, 1000V, 90 °C construction

• CSA AWM I/II A/B, 1000V, 90 °C construction

IEC and VDE standards –

See Kinetix 2090-Series Single Motor Cables Quick Reference,

publication 2090-QR002

, for more information on IEC and VDE

standards.

Materials

TPE jacket with superior mechanical and chemical properties

• PVC and PUR jacket with durable mechanical and chemical

properties

• PUR (LF) is Halogen Free materials to IEC 60754-1, UL 2885

100% braid coverage for best EMC performance 85% braid coverage for better EMC performance

Rated flex-cycles

(linear flexing applications)

• 10, 14, and 18 AWG continuous-flex cables and continuous-flex extension

cables are suitable for 20 million flex-cycles at 10 times cable diameter.

10 million flex-cycles in bending (tic-toc) applications.

• 6 and 8 AWG continuous-flex cables and continuous-flex extension cables

are suitable for 6.5 million flex-cycles at 10 times cable diameter

• 6, 8, 10, 14, and 18 AWG continuous-flex cables and continuous-flex

extension cables are suitable for 10 million flex-cycles at 7 times

cable diameter or 15 million flex-cycles at 10 times cable diameter

• 5 million cycles in bending (tic-toc) applications

Bend radius specifications

• Static bend radius - 7x OD

• Continuous bend radius - 10x OD

• Static bend radius - 5x OD

• Continuous bend radius - 7x OD (PUR only)

General specifications

105 °C (221 °F) rated temperature 90 °C (194 °F) rated temperature

FT4 flame test rated, VW-1 FT1 flame test rated, VW-1

UL OIL RES I/II

•UL 1581

• EN 50363-10-2 (PUR)

• EN 50363-4-1 (PVC)

Best EMC/EMI performance Better EMC/EMI performance

Compatible rotary motors Kinetix VPL, VPC-Bxxxxx-Q, VPF, VPH, and VPS servo motors

Compatible linear actuators Kinetix VPAR electric cylinders

Compatible servo drives

•Kinetix 5500

•Kinetix 5700

Loading...

Loading...