, for product specifications.

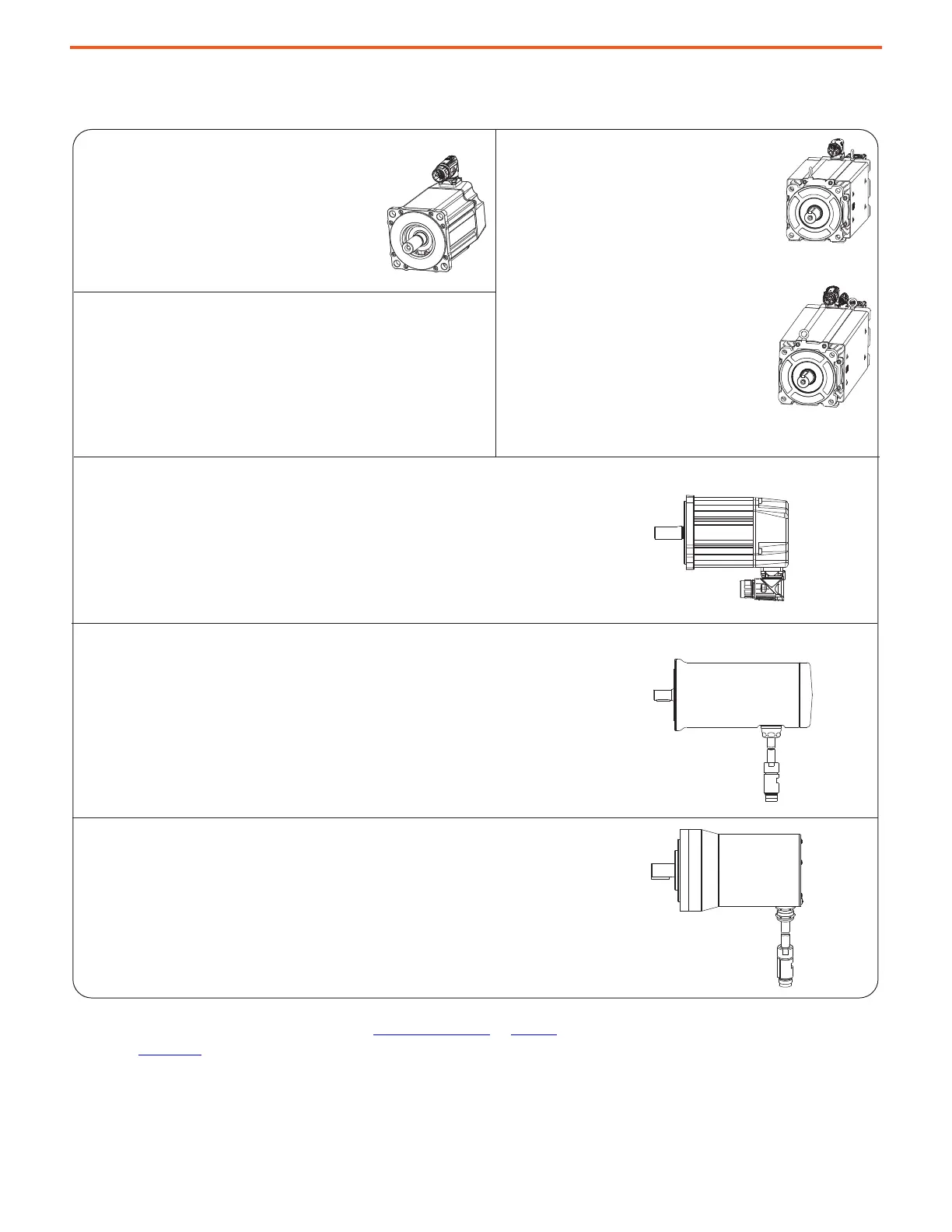

• Developed to match Kinetix 5500 and Kinetix 5700

drive ratings for optimized system sizing

• 2090-Series single-cable technology

• 200V and 400V-class motors

• Shaft-end threaded hole

• Multi-turn and single-turn high-resolution absolute

position encoders

Kinetix VP Servo Motors

• High-energy rare-earth magnets

• Absolute multi-turn digital encoder options, SIL 2 (PL d) rated (Hiperface DSL protocol)

• SpeedTec DIN connector, rotates 325°

• IP50 minimum, without shaft seal (standard)

• IP66 with optional shaft seal and the use of Rockwell Automation® factory-delivered

2090-Series single cable

• 0.46…33 N•m (4…292 lb•in) continuous stall torque

Kinetix VPL low-inertia servo motors are based on proven Kinetix MP technology for

dynamic performance, increased reliability, and leverages high volume production.

Kinetix VPS stainless-steel motors are specifically designed to meet the unique needs of washdown environments such as those

found in food and beverage, dairy, meat processing, and pharmaceutical manufacturing equipment.

• Specifically designed for sanitary environments for use with high-pressure, highly caustic washdown applications

• Smooth passivated 300-series stainless-steel cylindrical exterior

• Absolute multi-turn digital encoder (Hiperface DSL protocol)

• Complies with NSF/ANSI Standard 169

• On-motor cable extension, 5 m (16.4 ft)

• IP66/IP67 with shaft seal and slinger (standard) and the use of Rockwell Automation factory-delivered 2090-Series single cable

(includes on-motor cable connectors).

• IP69K for 1200 psi motor washdown with shaft seal and slinger (standard). Does not include on-motor cable connector.

• 8.1 and 21.0 N•m (72 and 186 lb•in) continuous stall torque

• Configurable winding options, brakes, and encoder feedback

• Food-grade epoxy coating

• Absolute multi-turn digital encoder options, SIL 2 (PL d) rated (Hiperface DSL protocol)

• SpeedTec DIN connector, rotates 315°

• IP66/IP67 with shaft seal (standard) and the use of Rockwell Automation factory-delivered 2090-Series single cable

• 0.93…19 N•m (8…172 lb•in) continuous stall torque

Kinetix VPF food-grade servo motors address the challenges of food environments by incorporating food-grade paint

and shaft seal, along with noncorrosive fasteners and stainless steel shaft.

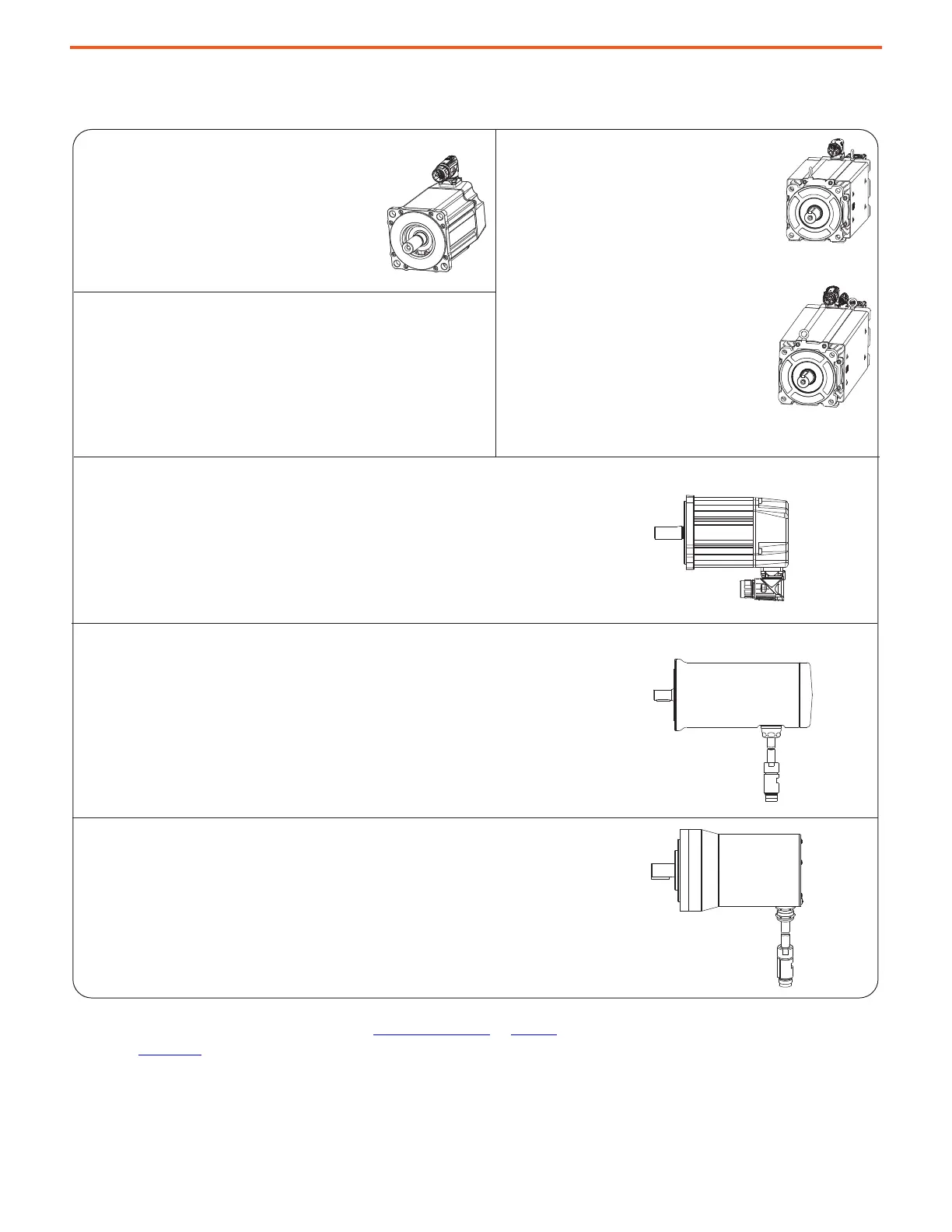

• Developed to match Kinetix 5700 (400V-class) drives for

optimized system sizing and performance

• Interior permanent-magnet technology with high-

energy rare-earth magnets

• Hiperface, Hiperface DSL and EnDat encoder protocols

• IP65 with shaft seal (standard) and the use of Rockwell

Automation factory-delivered 2090-CSxM1Dx single

cable or 2090-CxxM7Dx cable connectors

• 17.6…191 N•m (156…1691 lb•in) continuous stall torque

The Kinetix VPC continuous-duty servo motors for applications

with high-torque and high-speed demands.

VPC-Bxxxxx-Q

Servo Motors

VPC-Bxxxxx-S/-M/-Y

Servo Motors

VPC-Bxxxxx-S, VPC-B3004x-M, and VPC-Bxxxxx-Y servo motors

with 2090-CxxM7DF motor power and feedback cables.

•Absolute, multi-turn Hiperface DSL encoder protocol

• SIL 2 (PL d) rated encoder option

• SpeedTec DIN connector, rotates 325°

• Absolute, single-turn (-S) Hiperface encoder protocol

• Absolute, multi-turn (-M) Hiperface encoder protocol

• Absolute, multi-turn (-Y) EnDat encoder protocol

VPC-B

xxxxx-Q servo motors with single cable connector.

• Smooth, passivated, 316-grade stainless-steel cylindrical exterior

• Designed per EHEDG guidelines

•3A certified

• Absolute multi-turn digital encoder options, SIL 2 (PL d) rated (Hiperface DSL protocol)

• On-motor cable extensions available in 1…15 m (3.2 …49.2 ft) lengths with connector and flying-lead options

• IP66/IP67 with shaft seal (standard) and the use of Rockwell Automation factory-delivered 2090-Series single cable

(includes on-motor cable connectors).

• IP69K for 1200 psi motor washdown with shaft seal (standard). Does not include on-motor cable connector.

• 0.80…19 N•m (7…165 lb•in) continuous stall torque

Kinetix VPH hygienic stainless-steel servo motors are specifically designed to meet the unique needs of washdown environments

such as those found in food and beverage, dairy, meat processing, and pharmaceutical manufacturing equipment.

Loading...

Loading...