28 Rockwell Automation Publication KNX-SG001H-EN-P - December 2020

Product Features Comparison

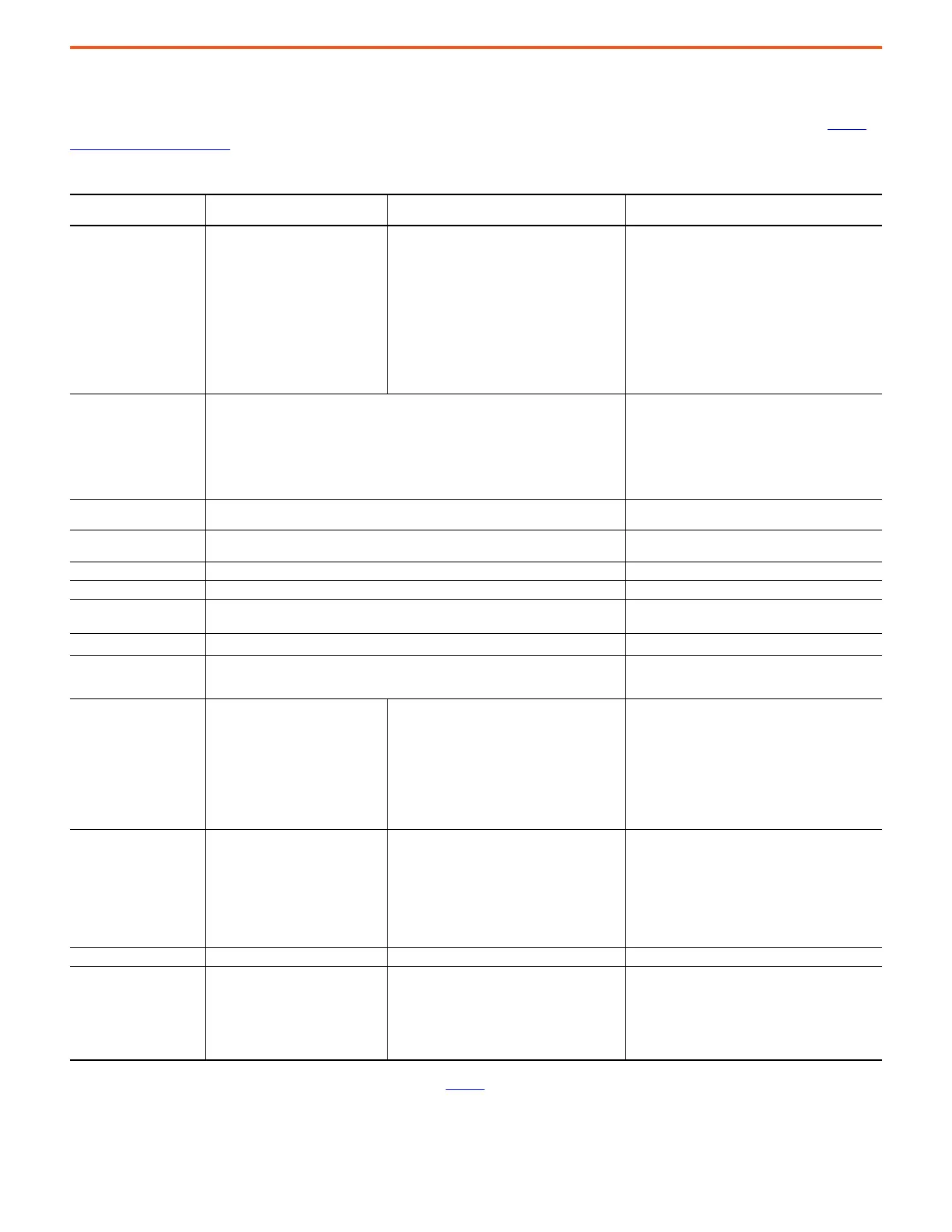

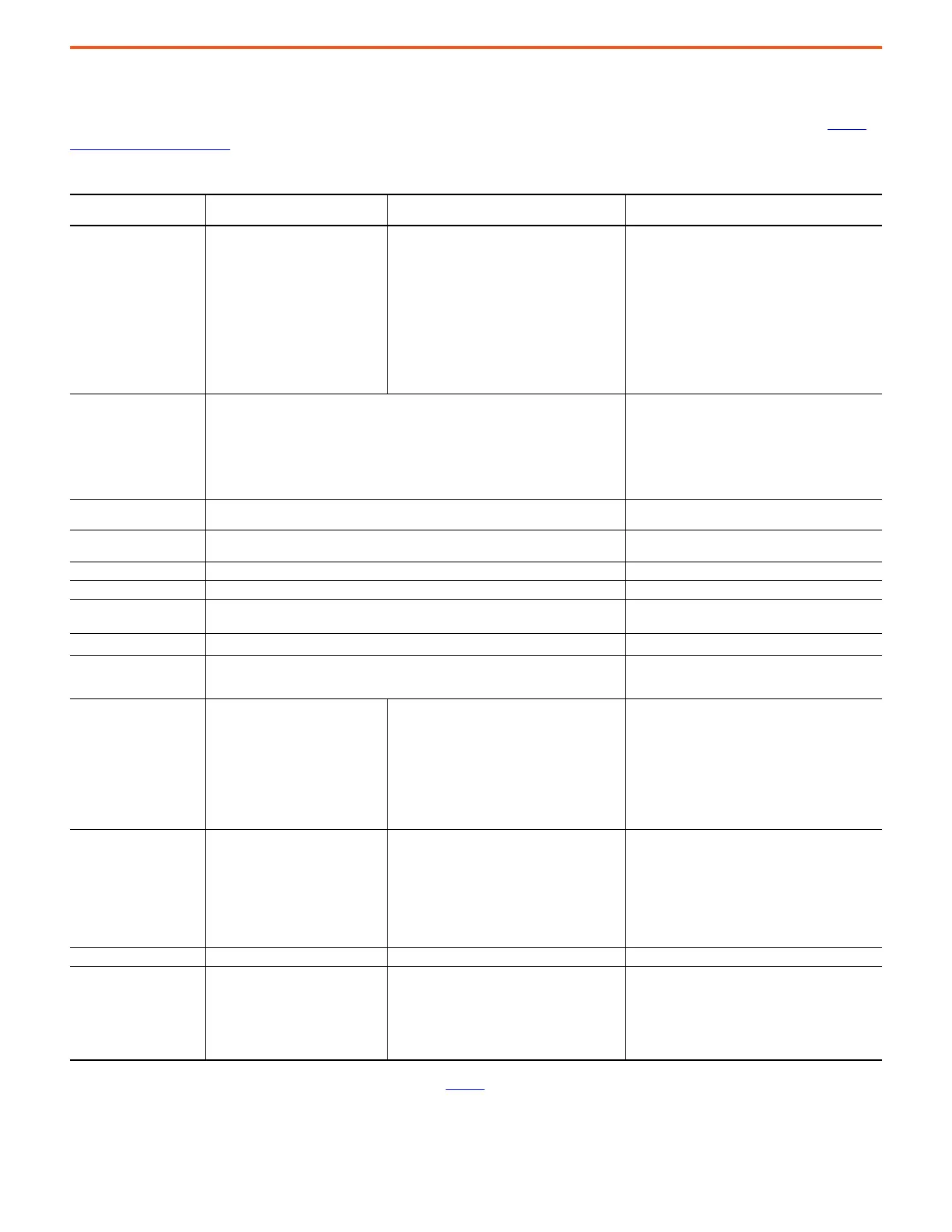

Linear Actuators

Actuators are UL Recognized components to applicable UL and CSA standards and CE marked for all applicable directives. Refer to http://

ab.rockwellautomation.com for more information.

Integrated Linear Actuators

Actuator Features

Kinetix MPAS

Integrated Linear Stages

Kinetix MPMA

Integrated Multi-axis Linear Stages

LDAT-Series

Integrated Linear Thrusters

Main characteristics

• Rugged linear stages with integrated

direct-drive linear motor or

ballscrew with Kinetix MP servo motor

• Available in three frame sizes (base

widths) to accommodate a variety of

load requirements for general

automation

• Smart Motor Technology (ballscrew)

• Very high linear speeds (direct drive)

• Out of box alignment of 30 arc seconds

• Field replaceable quick change cable management

for ease of maintenance

• Caged ball-type linear guides that retain lubrication

for longer bearing life and provide lower noise

levels

• Absolute encoders on ballscrew axis and

incremental encoders on direct-drive linear motor

axis

• Kinetix MP motor power and feedback connectors

for connection to Allen-Bradley extension cables

and drives

• Access holes for easy lubrication

Precise, high-speed, iron-core linear actuators with a built-

in linear guide. As a pre-engineered solution, the integrated

linear thrusters can help:

• Reduce engineering, design, and documentation time

• Decrease the amount of mechanisms and components

needed to build a custom solution

• Reduce the time to install the axis into a machine

• Increase reliability due to direct-drive technology with

single linear guide, single wear item, caged-ball linear

bearings, and elimination of wear items associated with

rotary to linear motion conversion

Features

• 200/230V and 400/460V operation (only 230V operation for direct-drive 150 mm frame size)

• High-energy (rare-earth) magnets

• Heavy duty connectors

• Operation without limit and home switches

• Carriage and base mounting design allows 200 mm and 250 mm frame sizes to be stacked

• Standard Kinetix MP motor power and feedback connectors

• Optional air purge kit for added protection against ingress of foreign substances

• Integrated linear bearing provides the ability to carry a

load without having to mount and align external

bearings

• Optimal strip cover for added bearing protection in

harsh environments

• Multiple mounting surfaces and methods for ease of

mounting into your machine

• Couples directly to the item that needs to be moved

Actuator type

• Direct-drive linear stage

• Ballscrew-drive linear stage

• Direct-drive linear thrusters

• Frame sizes 30, 50, 75, 100 and 150 mm

Environmental rating

Unique, long life strip seal system provides IP30 environmental rating to prevent debris, larger

than 2.5 mm (0.1 in.) diameter, from entering the linear stage

IP30 (with strip cover option)

Continuous forces 83…521 N (19…117 lb) 81…1997 N (18…449 lb)

Peak forces 312…1212 N (70…273 lb) 168…5469 N (38…1229 lb)

Peak velocities 200…5000 mm/s (7.9…196.9 in/s)

Up to 5 m/s (16 ft/s), and acceleration,

49 m/s

2

(160 ft/s

2

) std.

Stroke lengths

(1)

(1) Applies to Kinetix MPAS linear stages. Not all Kinetix MPAS stroke lengths (travels) are available with Kinetix MPMA multi-axis linear stages.

120…1940 mm (4.7…76.4 in.) 100…900 mm (4.0…35.0 in.)

Feedback options

• Multi-turn, high-resolution absolute position (ballscrew)

• 5 micron resolution incremental magnetic linear encoder (direct drive)

• Incremental, magnetic scale, 5 µm resolution

• Absolute, magnetic scale, Hiperface, compatible with

only Kinetix 300 servo drives

Field-installable accessories

• Cable track module replacement kit

• Strip seal replacement kit

•Top cover

•Side cover

•Coupling

• T-nut kit (package of 10)

• Toe-clip kit (package of 10)

• Grease gun kit

• Grease replacement cartridge

• Cable track module replacement kit

• Strip seal replacement kits

• Top cover kits (for only Y or Z-axis)

•Side cover kits

• Coupling kits (for only Y or Z-axis)

• Tee-nut kit (package of 10)

•Tee-nut bar kit

• Grease gun kit

• Grease replacement cartridge

• Rotary servo motor (for only Y or Z-axis)

Mounting Attachments:

• Foot mounting

• Clevis (male) flange

• Clevis (female) swivel flange

Slider-end Attachments:

•Rod-eye kit

•Rod-clevis kit

• Rod-coupler kit

• Horizontal payload mounting bracket

• Counterbalance kit

Compatible drives

(2)

(2) For Kinetix 2000 and Kinetix 3 drive specifications, refer to Additional Resources on page 233 for links to the applicable technical data and design guide publications.

•Kinetix 5700

•Kinetix 5300

• Kinetix 5500 (ballscrew only)

• Kinetix 6000 and Kinetix 6200/6500

• Kinetix 300

(ballscrew and direct-drive)

• Kinetix 350 (ballscrew only)

• Kinetix 3 (direct-drive only)

• Kinetix 2000

•Kinetix 5700

•Kinetix 5300

• Kinetix 5500 (ballscrew only)

• Kinetix 6000 and Kinetix 6200/6500

• Kinetix 300 (ballscrew and direct-drive)

• Kinetix 350 (ballscrew only)

• Kinetix 2000

•Kinetix 5700

• Kinetix 5500

•Kinetix 5300

• Kinetix 6000 and Kinetix 6200/6500

• Kinetix 300

•Kinetix 3

• Kinetix 2000

Servo cable compatibility 2090-CxxM7xx cables 2090-CxxM7xx cables 2090-CxxM7xx cables

Typical applications

• Electronic assembly

• Pick and place

• Robots

•Inspection

•Labeling

• Dispensing

• Micro-arraying

• Material handling

• Pick and place

• Dispensing

•Scanning

•Contouring

• Contoning

• Flying shape cutting

Applications that currently use a custom-designed belt

actuator or linkage device that converts rotary motion into

linear, including cartoners, stackers, case packers, case

and tray formers, in-out feeds, diverters, ejectors, drop

gates, and horizontal conveyors.

Loading...

Loading...