Rockwell Automation Publication KNX-SG001H-EN-P - December 2020 27

Product Features Comparison

Linear Servo Motors

Linear motors are UL Recognized components to applicable UL and CSA standards. CE marked for all applicable directives. Refer to http://

ab.rockwellautomation.com for more information.

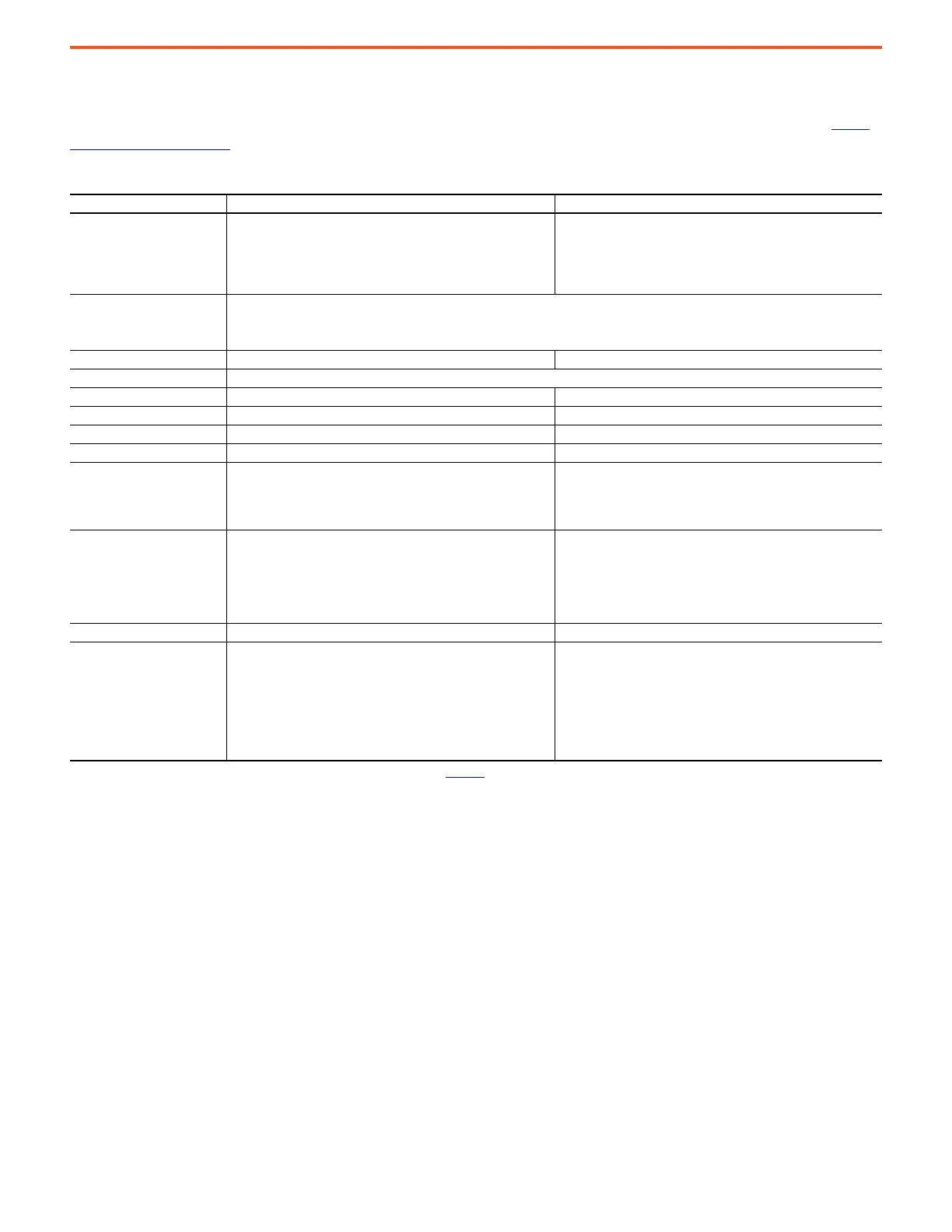

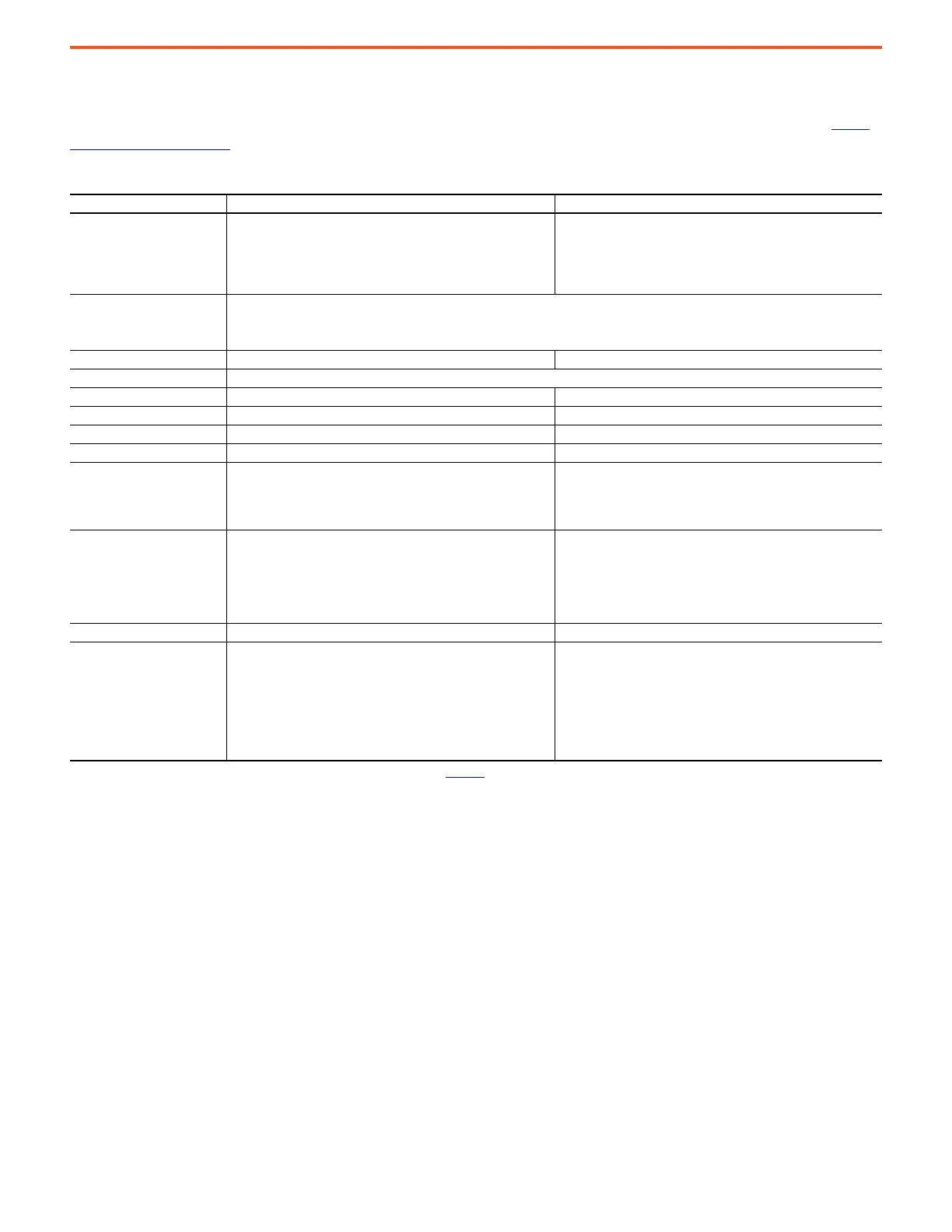

LDC-Series and LDL-Series Linear Servo Motors

Linear Motor Features LDC-Series Linear Servo Motors LDL-Series Linear Servo Motors

Main characteristics

• High thrust force to cost ratio for less costly solutions

• Cogging torque < 5% of the continuous force

• 230/400 and 460V AC operation

• Non-cogging technology for super smooth motion

• No magnetic attraction between the coil and magnet channel allows for

the use of smaller, less expensive linear bearings

• No external magnetic field to have to shield in magnetic sensitive

applications

•230V AC operation

Features

• Speed capabilities to 10 m/s (32.8 ft/s) to increase machine productivity

• Direct drive technology for extreme servo responsiveness

• No wear parts to increase machine productivity through less maintenance and replacement

• Standard Kinetix MP motor power and feedback connectors to easily combine with Allen-Bradley extension and flex cables

Motor type Iron core coil and magnet track Ironless coil and magnet channel

Environmental rating IP65 and RoHS compliant

Continuous forces 74…2882 N (17…648 lb) 63…596 N (14…134 lb)

Peak forces 188…5246 N (42…1179 lb) 209…1977 N (47…444 lb)

Peak velocity 10 m/s (32.8 ft/s) 10 m/s (32.8 ft/s)

Cogging torque < 5% of the continuous force Zero

Field-installable accessories

•Cooling plates

• Bulkhead connector kit

• Encoder connector kit

• Hall sensor for connectorized coil

• Hall sensor for flying-lead coil

• Bulkhead connector kit

• Encoder connector kit

• Hall sensor for connectorized coil

• Hall sensor for flying-lead coil

Compatible drives

(1)

(1) For Kinetix 2000 and Kinetix 3 drive specifications, refer to Additional Resources on page 233 for links to the applicable technical data and design guide publications.

• Kinetix 5700

• Kinetix 5300

• Kinetix 6200/6500

• Kinetix 6000

• Kinetix 300

• Kinetix 3

• Kinetix 2000

• Kinetix 5300

• Kinetix 6000

• Kinetix 300

• Kinetix 3

• Kinetix 2000

Servo cable compatibility 2090-CxxM7xx cables 2090-CxxM7xx cables

Typical applications

• Form-fill and seal packaging machines

• Large format gantries (pick and place, scribing and palletizing)

• Material handling (pallet movers and sheet glass)

• Plasma, laser and water jet cutting machines

• Machine tools

• Flying cut off machines

• Coordinate measuring machines

• Large format routers

• Large format printers (step axis)

• Wafer cutting, handling and marking

• Computer-to-plate printing machines

• Large format printing (print head axis)

• Solar and flat panel scribing (scribe head axis)

• Axis requiring extremely smooth/constant velocity

Loading...

Loading...