4.43

Date Code 20150130 Instruction Manual SEL-787 Relay

Protection and Logic Functions

Basic Protection

Time-Overcurrent Curves

The following information describes the curve timing for the curve and time

dial settings made for the time-overcurrent elements (see Table 4.16 and

Table 4.17). The U.S. and IEC time-overcurrent relay curves are shown in

Figure 4.25 through Figure 4.34. Curves U1, U2, and U3 (Figure 4.25 through

Figure 4.27) conform to IEEE C37.112-1996 IEEE Standard Inverse-Time

Characteristic Equations for Overcurrent Relays.

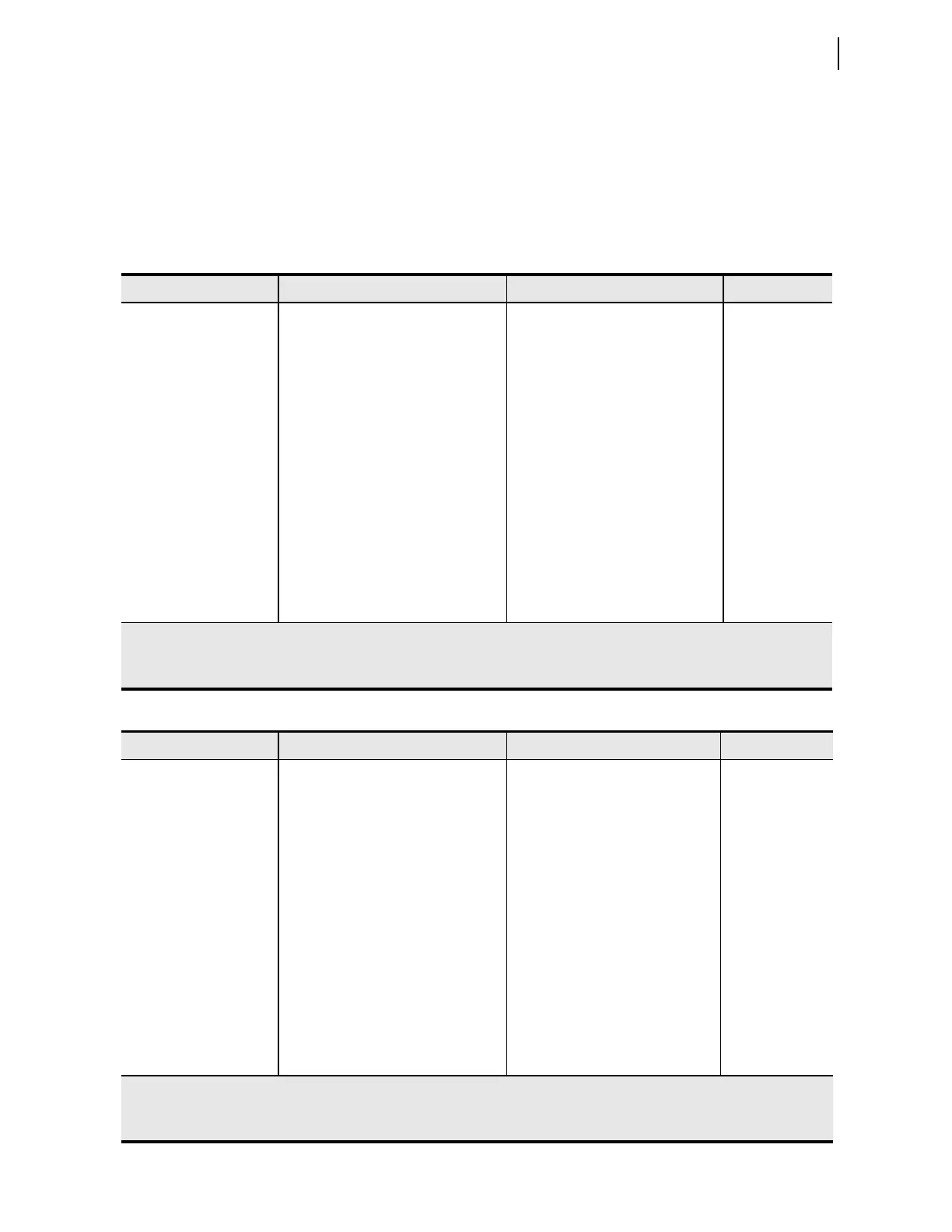

Table 4.16 Equations Associated With U.S. Curves

Curve Type Operating Time Reset Time Figure

U1 (Moderately Inverse)

Figure 4.25

U2 (Inverse)

Figure 4.26

U3 (Very Inverse)

Figure 4.27

U4 (Extremely Inverse)

Figure 4.28

U5 (Short-Time Inverse)

Figure 4.29

t

p

= operating time in seconds

t

r

= electromechanical induction-disk emulation reset time in seconds (if you select electromechanical reset setting)

TD = time-dial setting

M = applied multiples of pickup current [for operating time (t

p

), M >1; for reset time (t

r

), M 1]

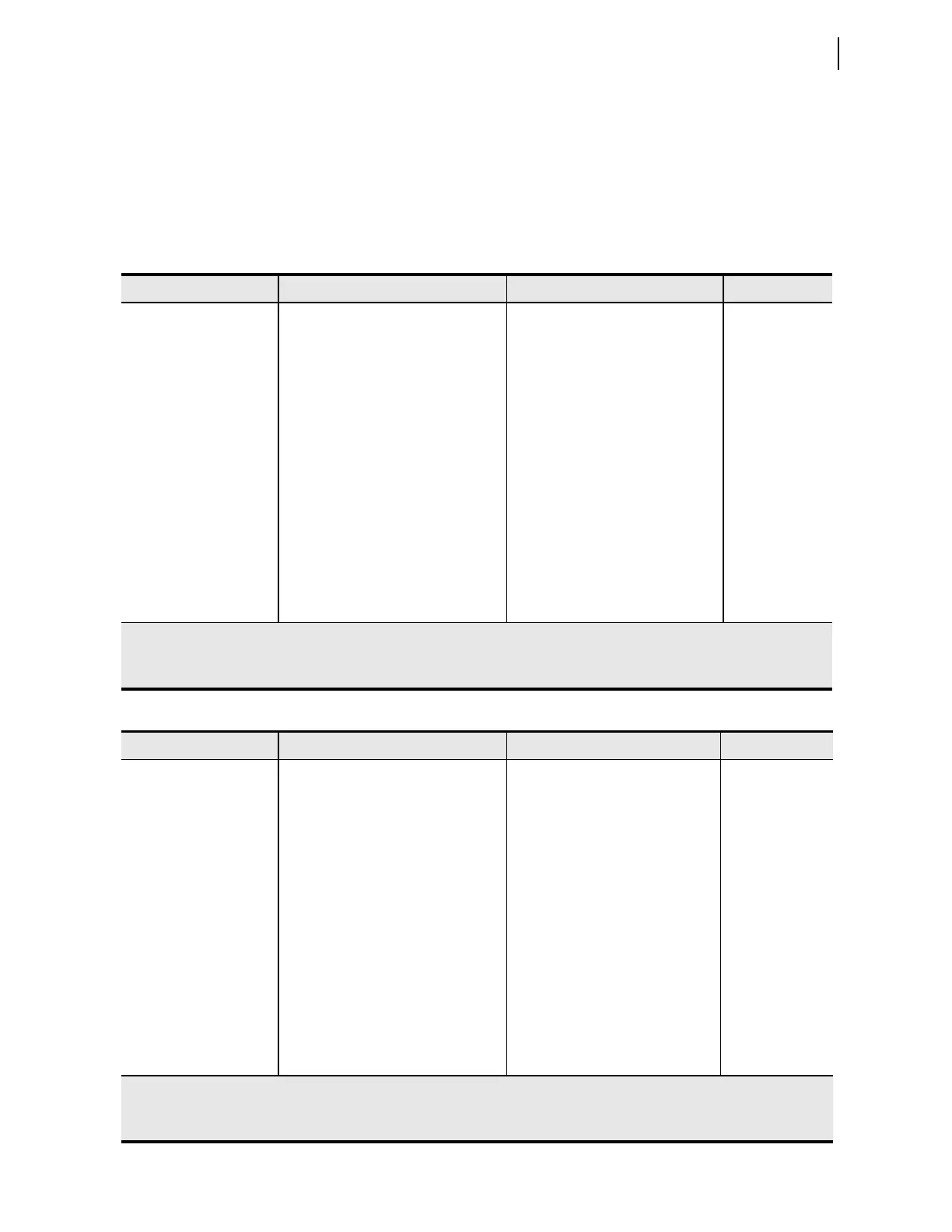

Table 4.17 Equations Associated With IEC Curves

Curve Type Operating Time Reset Time Figure

C1 (Standard Inverse)

Figure 4.30

C2 (Very Inverse)

Figure 4.31

C3 (Extremely Inverse)

Figure 4.32

C4 (Long-Time Inverse)

Figure 4.33

C5 (Short-Time Inverse)

Figure 4.34

t

p

= operating time in seconds

t

r

= electromechanical induction-disk emulation reset time in seconds (if you select electromechanical reset setting)

TD = time-dial setting

M = applied multiples of pickup current [for operating time (t

p

), M >1; for reset time (t

r

), M 1]

t

p

TD 0.0226

0.0104

M

0.02

1–

----------------------+

• =

t

r

TD

1.08

1M

2

–

----------------

• =

t

p

TD 0.180

5.95

M

2

1–

----------------+

• =

t

r

TD

5.95

1M

2

–

----------------

• =

t

p

TD 0.0963

3.88

M

2

1–

----------------+

• =

t

r

TD

3.88

1M

2

–

----------------

• =

t

p

TD 0.0352

5.67

M

2

1–

----------------+

• =

t

r

TD

5.67

1M

2

–

----------------

• =

t

p

TD 0.00262

0.00342

M

0.02

1–

----------------------+

• =

t

r

TD

0.323

1M

2

–

----------------

• =

t

p

TD

0.14

M

0.02

1–

----------------------

• =

t

r

TD

13.5

1M

2

–

----------------

• =

t

p

TD

13.5

M1–

--------------

• =

t

r

TD

47.3

1M

2

–

----------------

• =

t

p

TD

80

M

2

1–

----------------

• =

t

r

TD

80

1M

2

–

----------------

• =

t

p

TD

120

M1–

--------------

• =

t

r

TD

120

1M–

--------------

• =

t

p

TD

0.05

M

0.04

1–

----------------------

• =

t

r

TD

4.85

1M

2

–

----------------

• =

Loading...

Loading...