InstallingHydraulicHosesandTubes(O-RingFaceSeal)

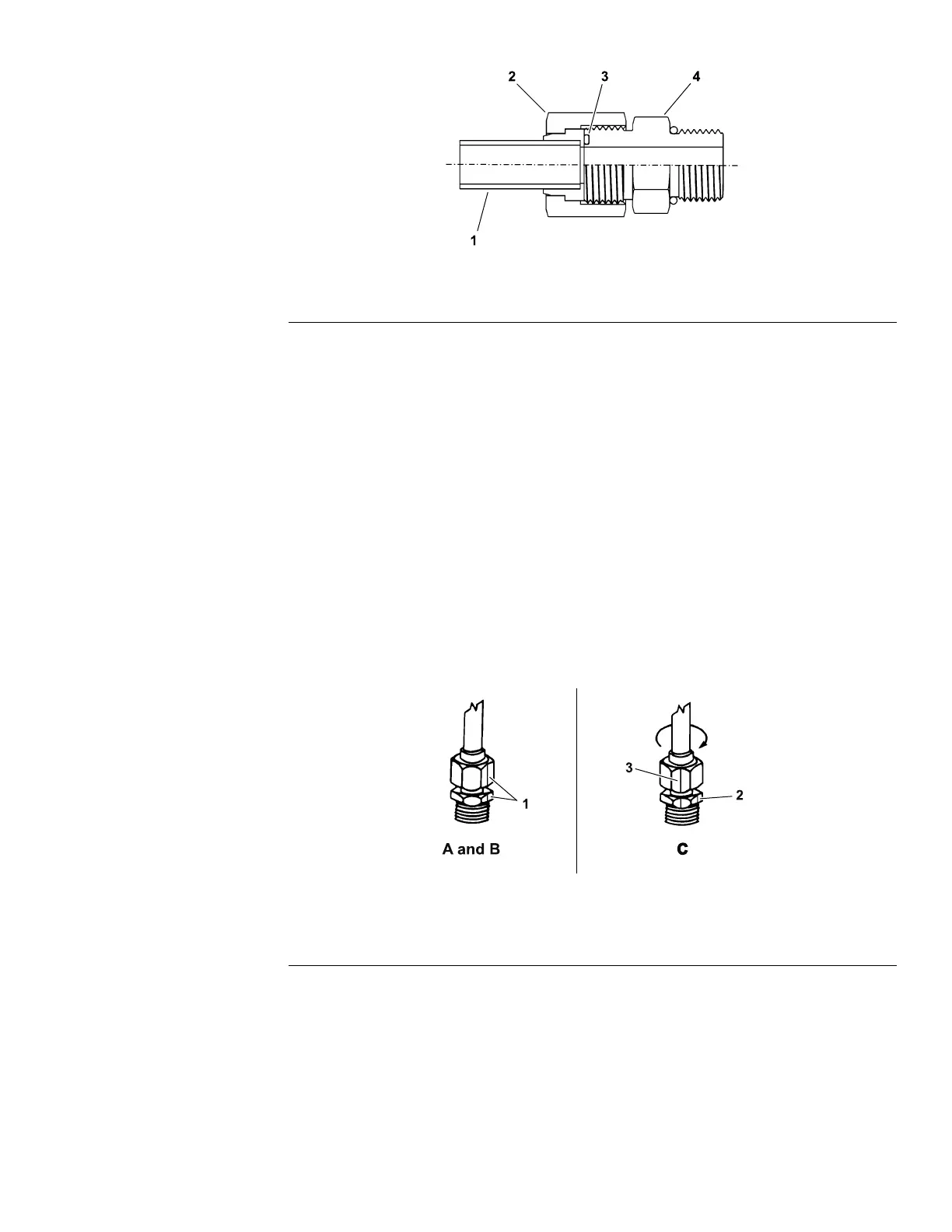

g212099

Figure31

1.Tubeorhose

2.Swivelnut3.O-ring

4.Fittingbody

1.Ensurethatallthethreads,thesealingsurfacesofthehose/tube,andthe

ttingarefreeofburrs,nicks,scratches,orunwantedmaterial.

2.Tohelppreventahydraulicleak,replacethefacesealO-ringwhenyouopen

theconnection.EnsurethattheO-ringisinstalledandcorrectlyseatedinthe

grooveofthetting.LightlylubricatetheO-ringwithcleanhydraulicuid.

3.Alignthehose/tubeagainstthebodyofthettingsothattheatfaceofthe

hose/tubesleevefullytouchestheO-ringinthetting(Figure31).

4.Useyourhandtothreadtheswivelnutontothetting.Whileyouholdthe

hose/tubeinalignmentwithawrench,useatorquewrenchtotightenthe

swivelnuttotherecommendedtorquevaluewithinthespeciedrangeof

torquevalues;refertotheHose/TubeInstallationT orqueTable(page5–8).

Thisproceduretotightentheswivelnutrequiresadrive-adapterwrench

(e.g.,crowfootwrench).

Note:Itmaybenecessarytouseadrive-adapterwrench(e.g.,crowfoot

wrench)toinstallahydraulictting;refertoCalculatingtheT orqueValues

WhenUsingaDrive-AdapterWrench(page2–8).

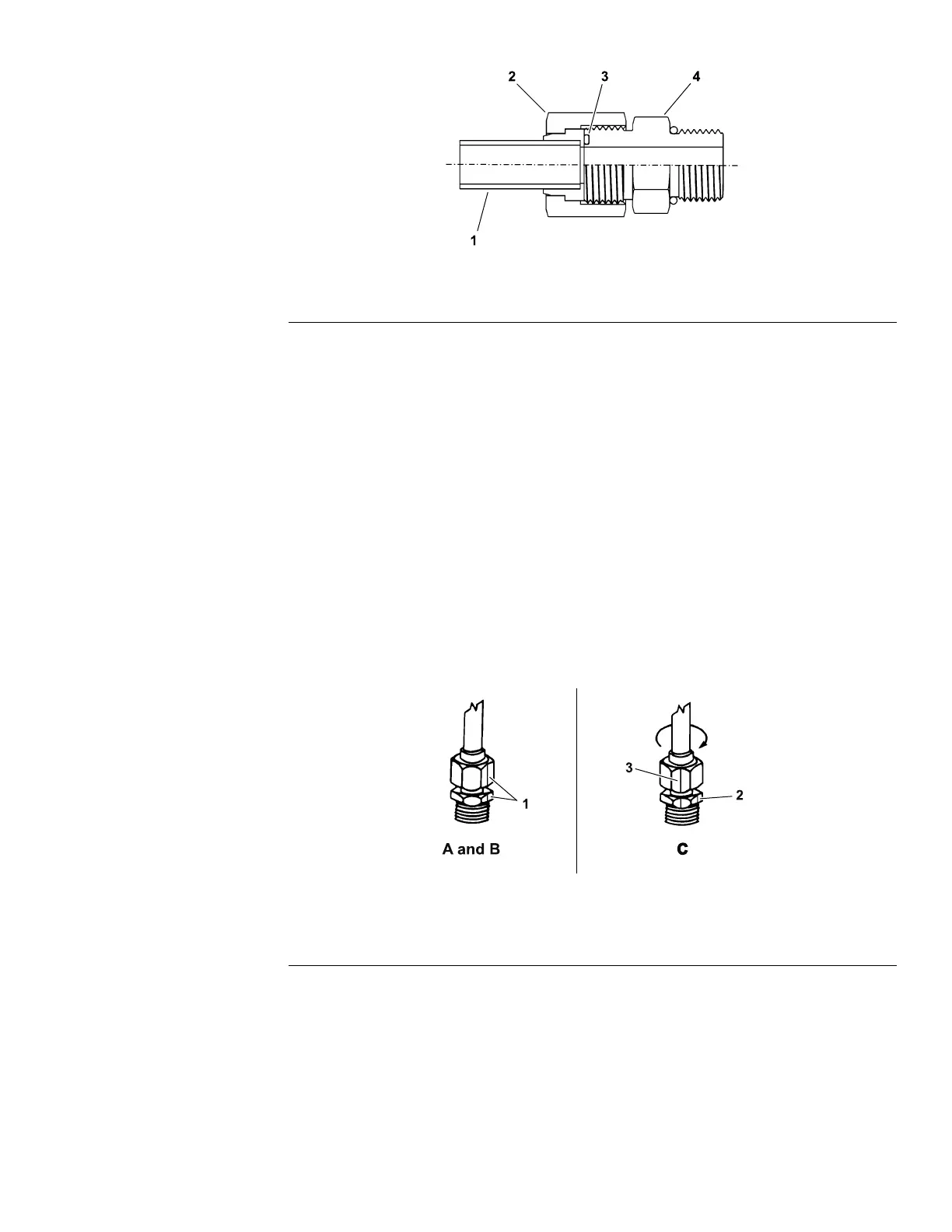

g212098

Figure32

1.Markswivelnutandtting

body

2.Initialposition3.Finalposition

Groundsmaster

®

5900&5910

Page5–7

HydraulicSystem:GeneralInformation

16227SLRevB

Loading...

Loading...