FilteringClosed−LoopTractionCircuit

Filteringofaclosed−loophydraulicsystemafteramajortractioncomponent

failure(e.g.traction(piston)pumporwheelmotor)isarequirementtoprevent

debrisfromtransmittingthroughoutthesystem.Ifaclosed−loophydraulic

systemlteringtoolisnotusedtoensuresystemcleanliness,repeatfailures,

aswellassubsequentdamagetootherhydrauliccomponentsintheaffected

system,willoccur.Toeffectivelyremovecontaminationfromclosed−looptraction

circuit,useoftheT orohighowhydrauliclterandhydraulichosekitsare

recommended(seeSpecialT ools(page2–15)).

1.Parkmachineonalevelsurface,lowercuttingdecksfully,disengagePTO

andstopengine.Removekeyfromkeyswitch.

2.Raiseandsupportmachinesoallwheelsareofftheground(seeJacking

Instructions(page1–6)).

Note:Ifwheelmotorwasreplaced,installhighowltertotheinletofthe

newmotorinsteadoftothepistonpumphose.Thiswillpreventsystem

contaminationfromenteringanddamagingthenewwheelmotor.

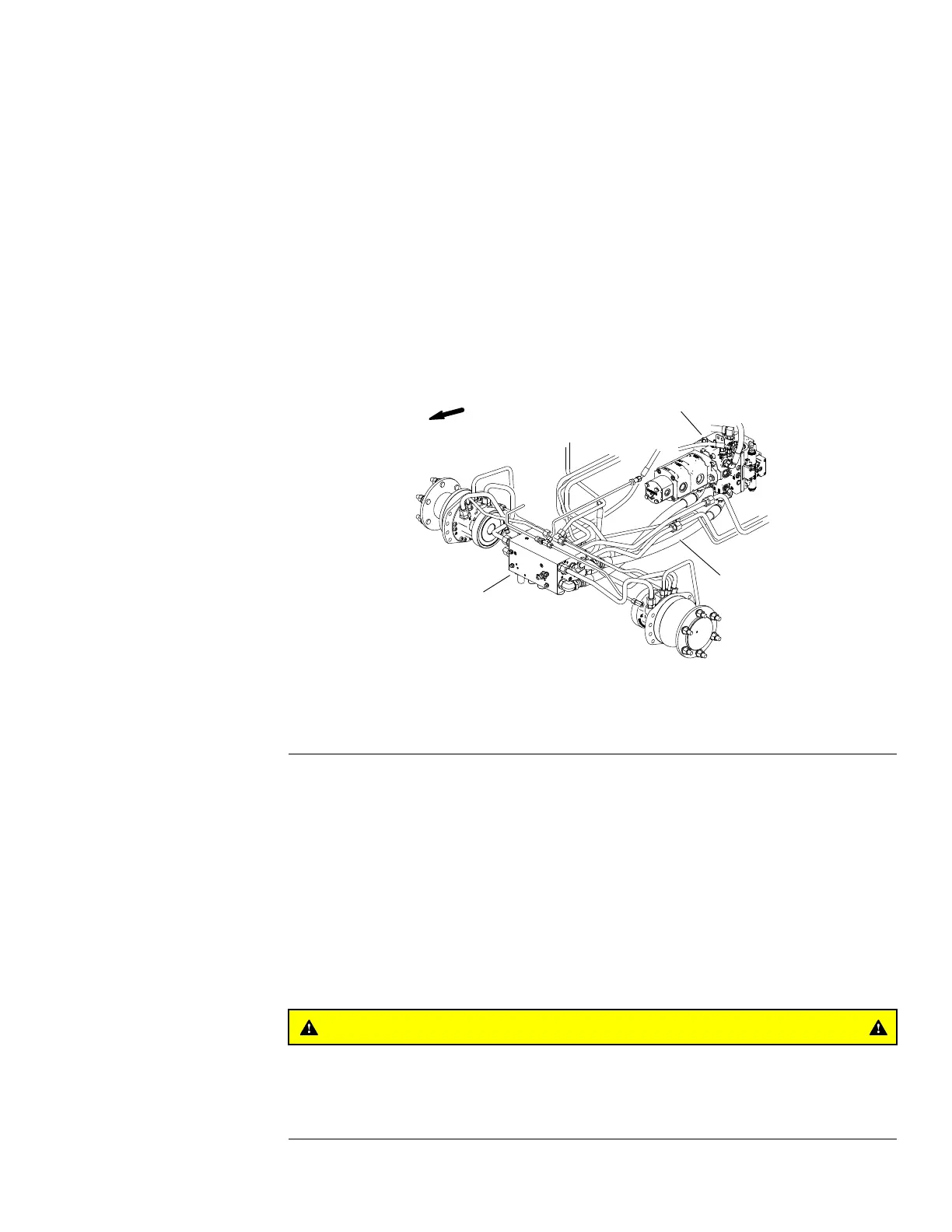

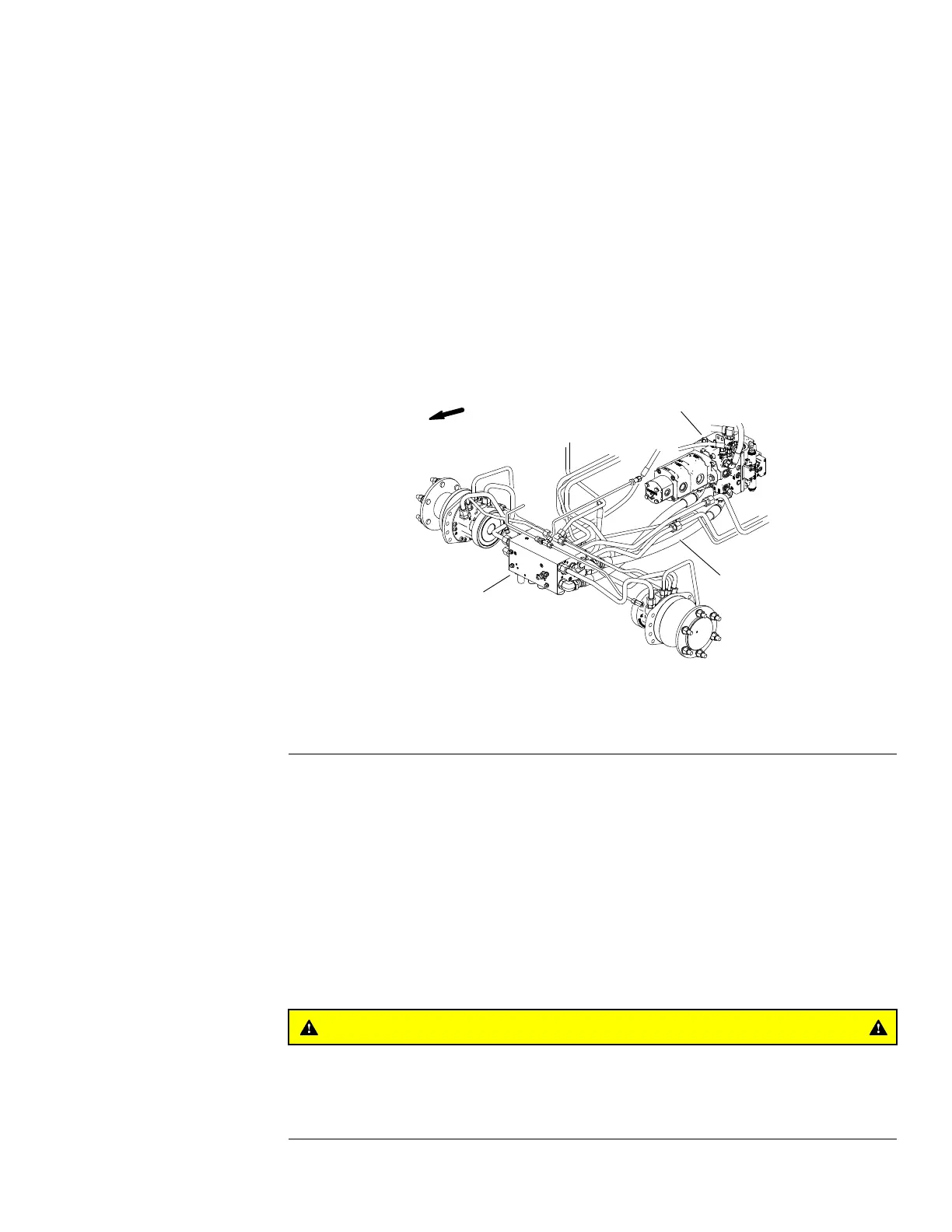

g287875

Figure78

1.Pistonpump

3.HosetoP2tting

2.Tractionmanifold

3.Thoroughlycleanjunctionofhydraulichosefrompistonpumpandelbow

ttingintheP2portonsideoftractionmanifoldwhichisattachedtothe

bottomofthefrontaxleframe(Figure78).Disconnecthosefromelbowtting.

4.ConnectT orohighowhydrauliclterinseriesbetweenmanifoldttingand

disconnectedhose.Usehydraulichosekit(seeSpecialT ools(page2–15))

toconnectltertomachine.Makesurethathoseconnectionsareproperly

tightened.

5.Afterinstallinghighowltertomachine,checkandllhydraulicreservoir

withnewhydraulicoilasrequired(seeOperator’sManual).

6.Startengineandrunatlowidlespeed.Checkforanyhydraulicleakagefrom

lterandhoseconnections.Correctanyleaksbeforeproceeding.

CAUTION

Allwheelswillbeoffthegroundandrotatingduringthisprocedure.

Makesuremachineiswellsupportedsoitwillnotmoveand

accidentallyfalltopreventinjuringanyonearoundmachine.

Groundsmaster

®

5900&5910

Page5–81

HydraulicSystem:ServiceandRepairs

16227SLRevB

Loading...

Loading...