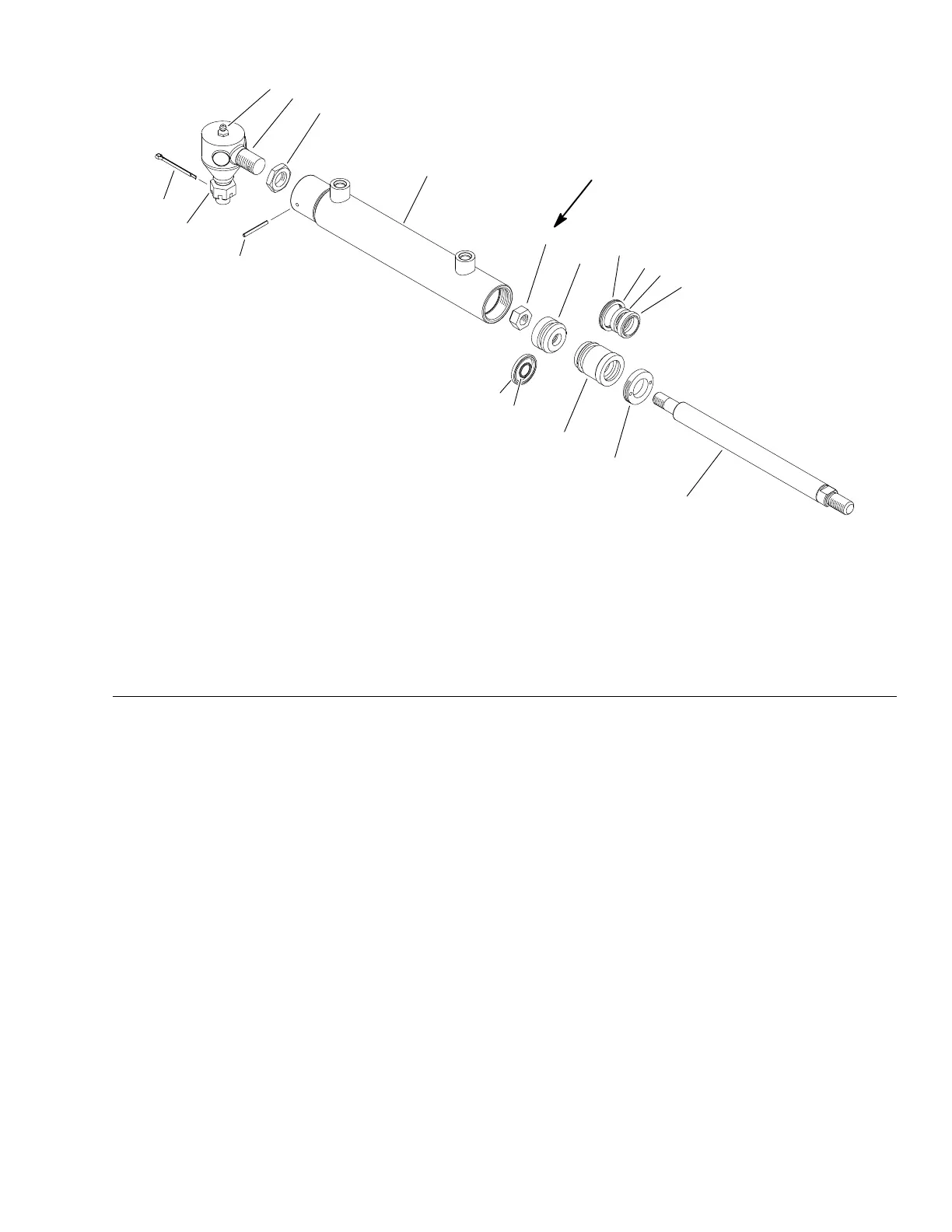

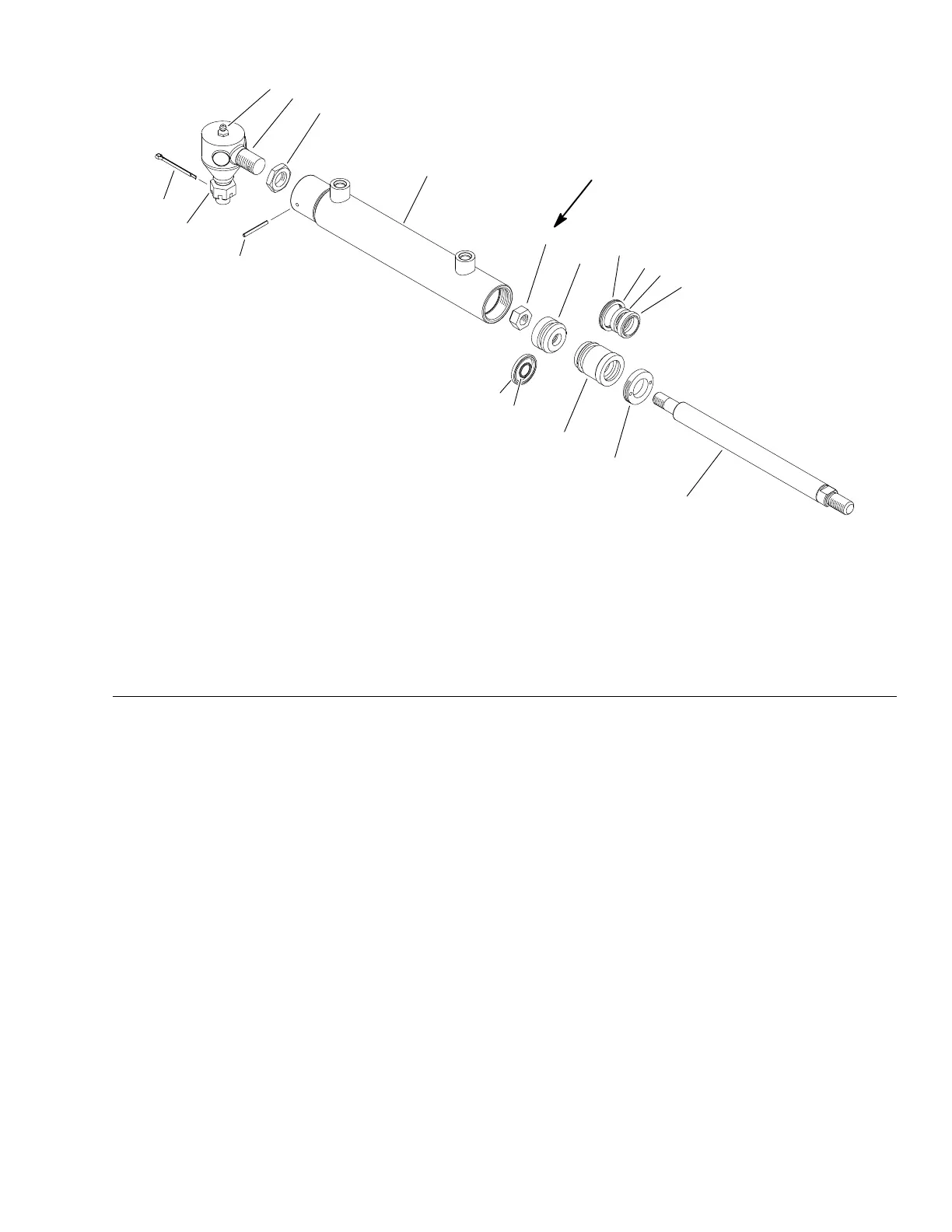

SteeringCylinderService

11

12

13

14

15

17

16

18

1

2

3

4

5

6

7

8

9

10

54 N·m

(40 ft−lb)

g288165

Figure124

1.Balljoint7.Barrel

13.O−ring

2.Greasetting

8.Locknut14.Back−upring

3.Jamnut9.Piston15.Rodseal

4.Cotterpin

10.Pistonseal16.Rodwiper

5.Castlenut11.O−ring

17.Internalcollar

6.Rollpin12.Head18.Pistonrod

SteeringCylinderDisassembly(Figure124)

1.Removeoilfromsteeringcylinderbyslowlypumpingthepistonrod.After

removingoilfromcylinder,plugbothportsandthoroughlycleantheoutside

ofthecylinder.

2.Removeinternalcollar(item17)thatsecuresheadinbarrel.

3.Graspendofpistonrodanduseatwistingandpullingmotiontocarefully

extractpiston,pistonrodandheadfromcylinderbarrel.

4.Usingawrenchonthepistonrodatstopreventtherodfromturning,remove

locknut(item8)fromrod.Removepistonandheadfromrod.

5.RemoveallsealsandO−ringsfromheadandpiston.

6.Washpartsincleansolvent.Drypartswithcompressedair.Donotwipeparts

drywithpapertowelsorcloth.Lintinahydraulicsystemwillcausedamage.

7.Carefullyinspectinternalsurfaceofbarrelfordamage(deepscratches,

out−of−round,etc.).Replaceentirecylinderifbarrelisdamaged.Inspect

pistonrodandpistonforevidenceofexcessivescoring,pittingorwear.

Replaceanydamagedparts.

8.Ifpistonrodballjointremovalisnecessary,loosencapscrewandlocknut

andthenunscrewballjointfrompistonrod.

Groundsmaster

®

5900&5910

Page5–141

HydraulicSystem:ServiceandRepairs

16227SLRevB

Loading...

Loading...