SteeringCylinderDisassembly(Figure124)(continued)

9.Ifnecessary,removebarrelendballjoint(item1)frombarrelasfollows:

A.Loosenjamnut(item3).

B.Driverollpin(item6)frombarrel.

C.Unscrewballjointfrombarrel.

SteeringCylinderAssembly(Figure124)

1.Useacompleterepairkitwhenrebuildingthecylinder.Putacoatingofclean

hydraulicoilonallnewsealsandO−rings.

2.InstallnewO−ringsandsealtothepistonandnewO−ring,back−upring,rod

sealandrodwipertohead.

3.Lubricateshaftwithcleanhydraulicoil.Slideheadandpistonontopistonrod.

4.Usingawrenchonthepistonrodatstopreventtherodfromturning,install

andtightenlocknut(item8).Torquelocknutto54N·m(40ft−lb).

5.Putacoatingofcleanhydraulicoilonallcylinderpartstoeaseassembly.

6.Carefullyslidepistonrodassemblyintocylinderbarreltakingcaretonot

damagesealsorO−rings.

7.Secureheadinbarrelwithinternalcollar.

8.Ifbarrelendballjoint(item2)wasremoved,installballjointtobarrelas

follows:

A.Threadballjointintobarrelsothatrollpinholeinjointalignswithhole

inbarrel.

B.Driverollpinintoalignedholesinbarrelandballjoint.

C.Tightenjamnut.

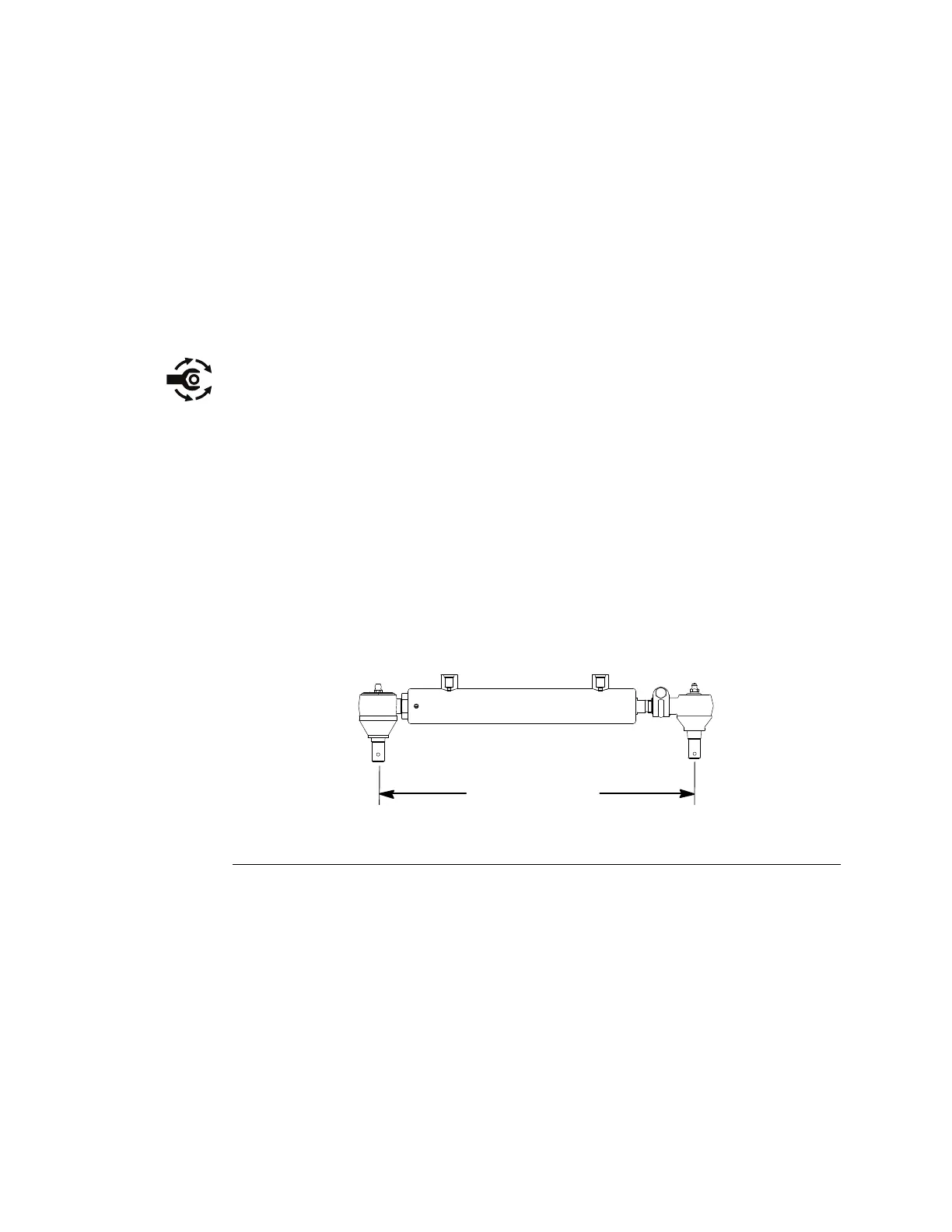

35.5 to 37.0 cm

(14.0 to 14.6 in)

g288166

Figure125

9.Ifpistonrodendballjointwasremoved,fullyretractpistonrodandthread

balljointontorodsothatcentertocenterlengthisfrom35.5to37.0cm(14.0

to14.6in)(Figure125).Orienttheheadoftheballjointclampscrewtoward

thefrontofthemachineandtightentheclampscrewandlocknut.

HydraulicSystem:ServiceandRepairs

Page5–142

Groundsmaster

®

5900&5910

16227SLRevB

Loading...

Loading...