ProcedureforDeckMotorCaseDrainLeakageTest(continued)

3.Install40GPMtester(owandpressure)inserieswiththedeckmotorand

thedisconnectedreturnhose.Makesuretheowcontrolvalveontester

isfullyopen.

4.Startengineandrunatlowidlespeed.Checkforhydraulicleaksattester

connectionsandmakecorrectionsifnecessarybeforeproceedingwithtest.

5.Increaseenginespeedandmakesurehydraulicoilisatnormaloperating

temperature(54to66ºC(130to150ºF))byoperatingthemachinefor

approximatelyten(10)minutes.Stopengineandremovekeyfromkey

switch.

6.Chockthewheelssothatthemachinewillnotmoveduringtesting.

7.Forthedeckmotortobetested,disconnectthemotorcasedrainhose(small

diameterhose)whereitconnectstothefrontPTOmanifoldteettingor

hydraulictubeatthesidePTOmanifold(notatthemotor).Putasteelcapon

theopenteettingortubeconnection;leavethecasedrainhoseopen.

CAUTION

CuttingdeckbladeswillrotatewhenloweredwithPTOswitchin

ONposition.Keepawayfromcuttingdecksduringtesttoprevent

personalinjuryfromrotatingblades.Donotstandinfrontofthe

machineduringtest.

8.Sitonseat,starttheengineandincreaseenginespeedtohighidlespeed

(2530RPM).Engagecuttingdecks.Donotdepressthetractionpedalduring

testingprocedure.

9.Whilewatchingtesterpressuregauge,haveasecondpersonslowlyclose

owcontrolvalveontesteruntilapressureof83bar(1200PSI)isobtained.

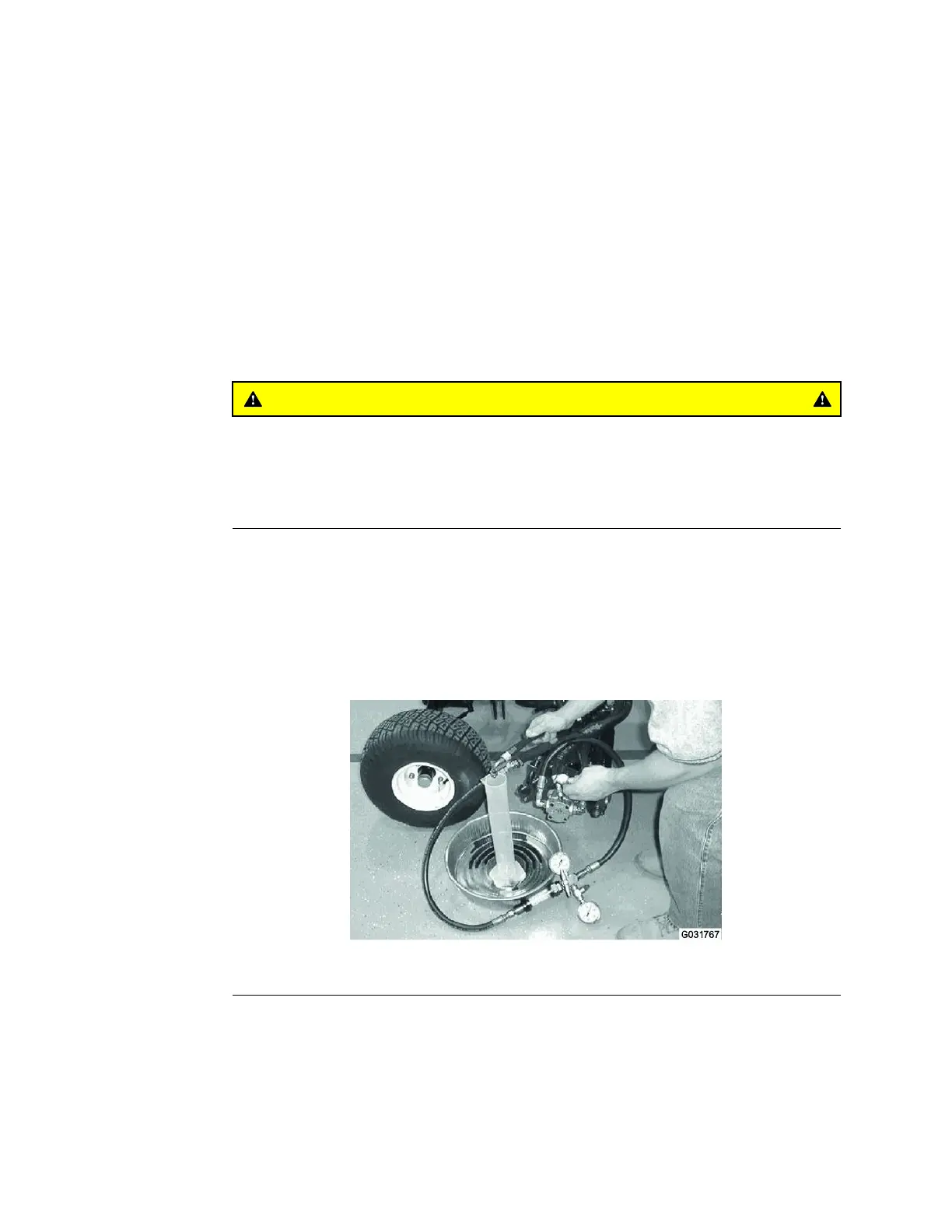

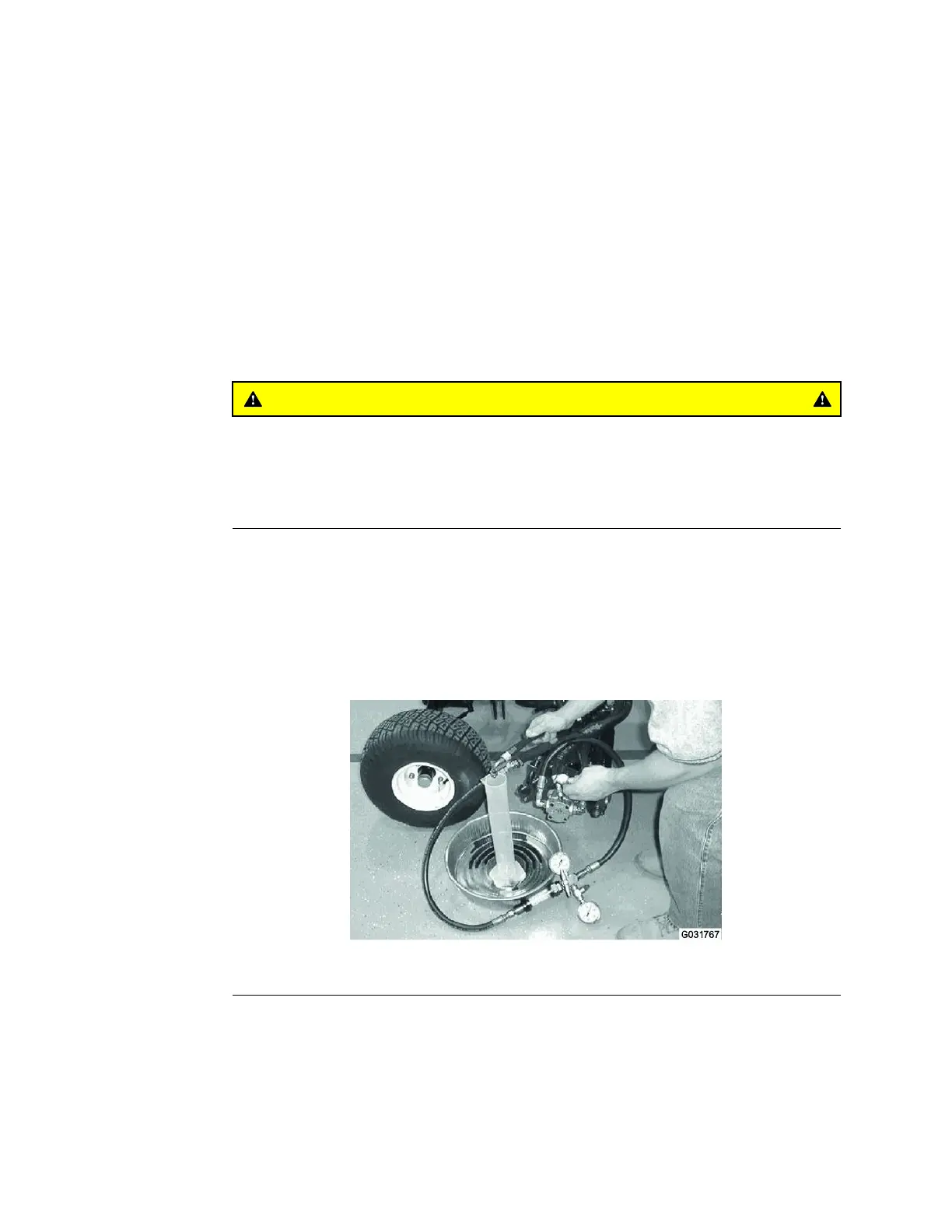

Note:Useagraduatedcontainer,specialtoolTOR4077,tomeasurecase

drainleakage.

g031767

Figure65

10.Havethesecondpersonmeasureowfromtheopencasedrainhosefor

fteen(15)seconds,thendisengagethecuttingdecks,openowcontrol

valveontesterandstoptheengine.Recordtestresults.

TESTRESULTS:Casedrainleakageshouldbelessthan672ml(23ounces)

ofhydraulicuidinfteen(15)seconds.

11.Ifcasedrainowismorethan672ml(23ounces),thedeckmotorisworn

ordamagedandshouldberepairedorreplaced.

HydraulicSystem:Testing

Page5–58

Groundsmaster

®

5900&5910

16227SLRevB

Loading...

Loading...