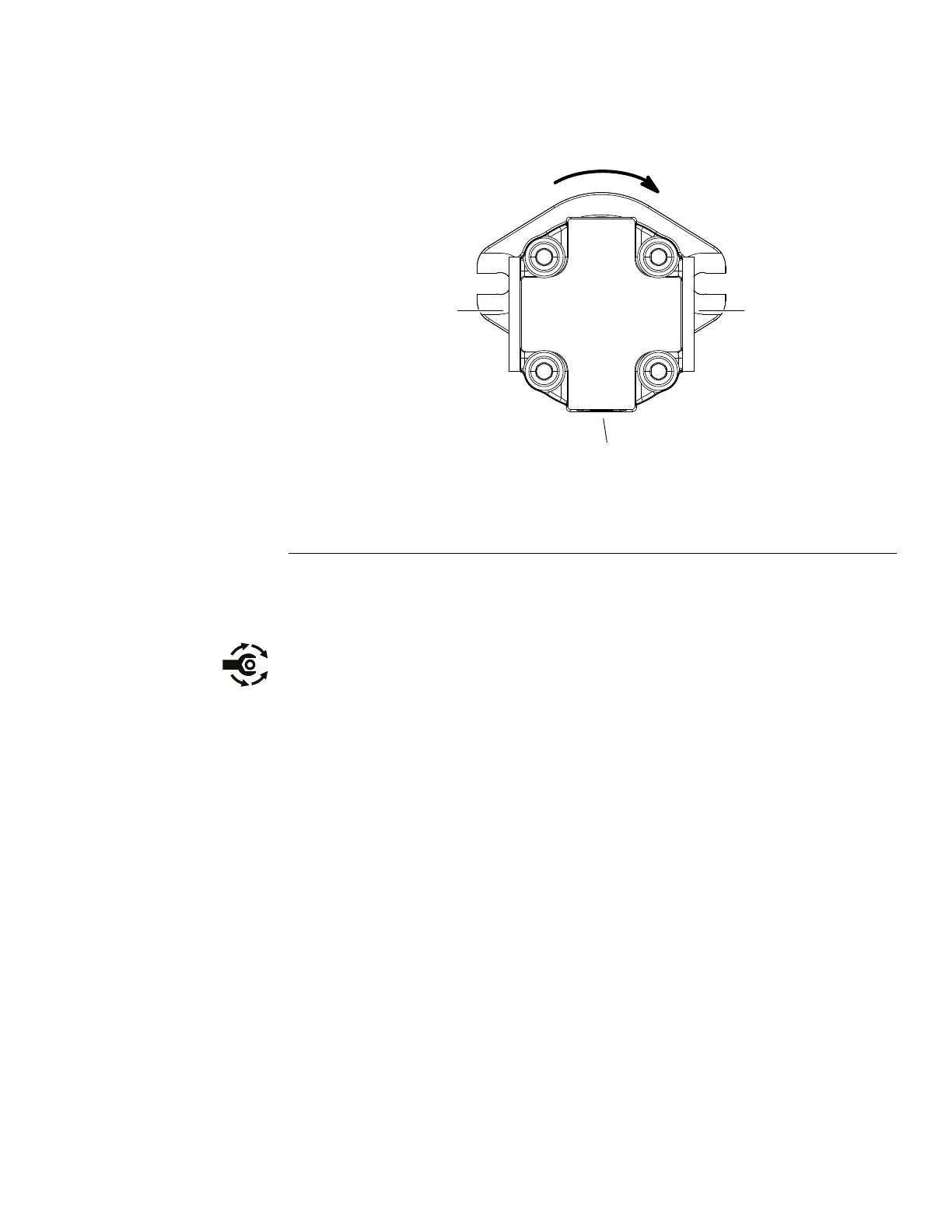

CuttingDeckMotorRemoval(Figure104)(continued)

8.Ifrequired,removehexnutandwasherthatsecurecouplerhubtomotor

shaft.Usesuitablepullertoremovehubfromshaft.Removewoodruffkey.

CuttingDeckMotorInstallation(Figure104)

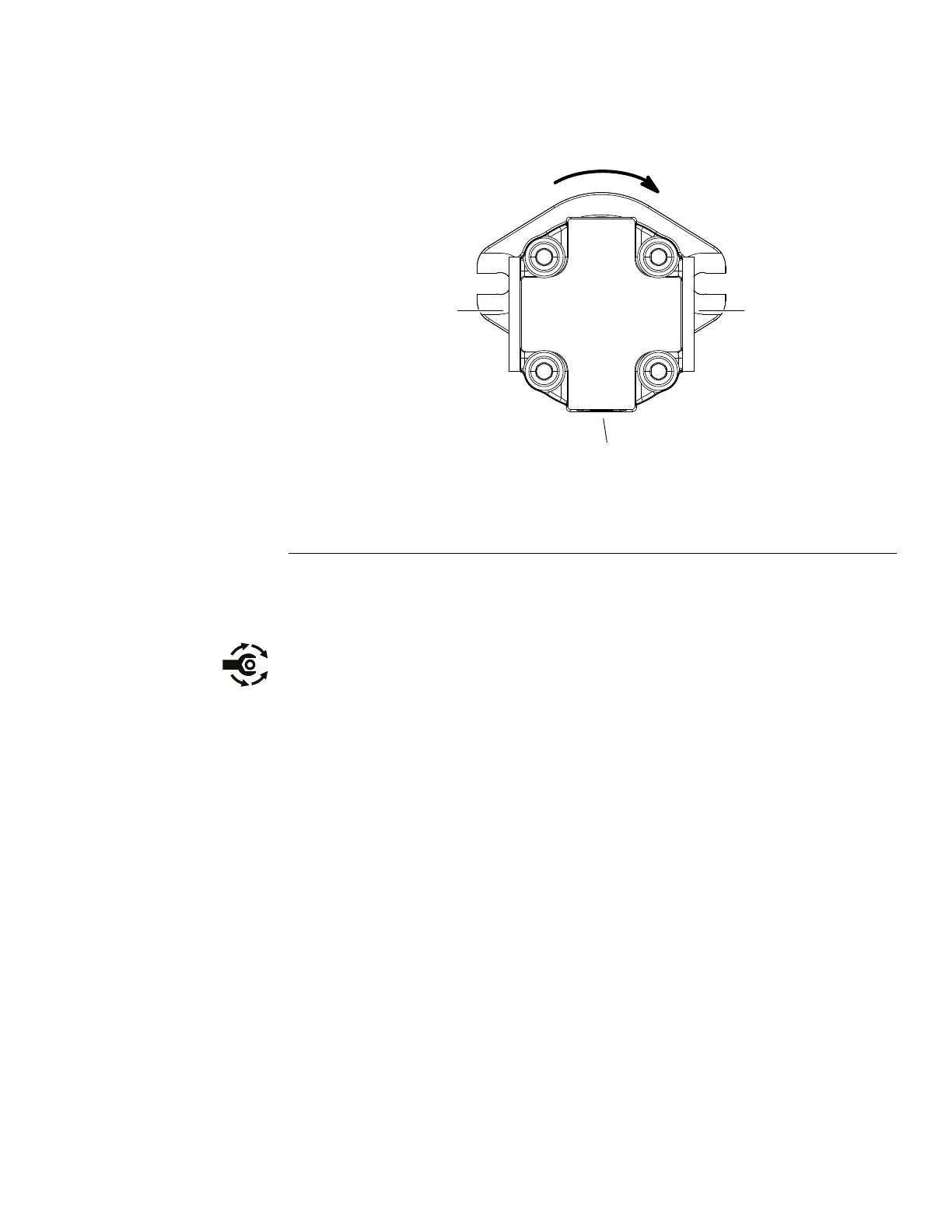

g288022

Figure105

1.Flow−in

3.Casedrain

2.Flow−out

1.Ifttingswereremovedfromdeckmotor,lubricateandplacenewO–rings

ontottings.Installttingsintomotorportsusingmarksmadeduringthe

removalprocesstoproperlyorientatettings.Tightenttings(seeInstalling

theHydraulicFittings(SAEStraightThreadO-RingFittings)(page5–9)).

2.Ifremoved,installwoodruffkeyandcouplerhubtomotorshaft.Securewith

washerandhexnut.Tightenhexnutfrom37to44N·m(27to33ft−lb).

3.Positionspider(item12)inspindlepulley.Aligncouplerhubonmotor

shaftwithspiderandplacedeckmotoronthemotormount.Makesurethe

shoulderofthedeckmotortssquarelyinsidethemotormountopening.

4.Securemotortocuttingdeckwithtwo(2)angeheadscrews.

Note:MakesureIN/OUThydraulichosesareattachedtocorrectdeckmotor

portsordeckbladeswillspinbackwards.

5.Removecapsorplugsfromhydraulicttingsandhoses.Uselabelsattached

duringremovalandconnecthydraulichosestodeckmotor(seeInstalling

HydraulicHosesandTubes(O-RingFaceSeal)(page5–7)).

6.Makesurehydraulictankisfull.Addcorrectoilifnecessary.

7.Afterassemblyiscompleted,raiseandlowercuttingunitsandverifythat

hydraulichosesandttingsarenotcontactedbyanymovingcomponents.

8.Checkhydraulicsystemforleaksbeforereturningthemachinetoservice.

Groundsmaster

®

5900&5910

Page5–119

HydraulicSystem:ServiceandRepairs

16227SLRevB

Loading...

Loading...