July, 2007

4-96

WorkCentre 5020

ADJ 10.3.1

Initial Issue

Repairs and Adjustments

ADJ 10.3.1 IIT Lead Edge/Side Edge Registration

Purpose

To obtain the home position in the IIT lead edge (slow scan)/IIT side edge (fast scan) direction.

Check

1. Set the Test Pattern 499T247 (A3) on the platen, so that there is no gap between it and

the Rear Registration Guide. Make 3 copies using 100% R/E and A3 SEF paper.

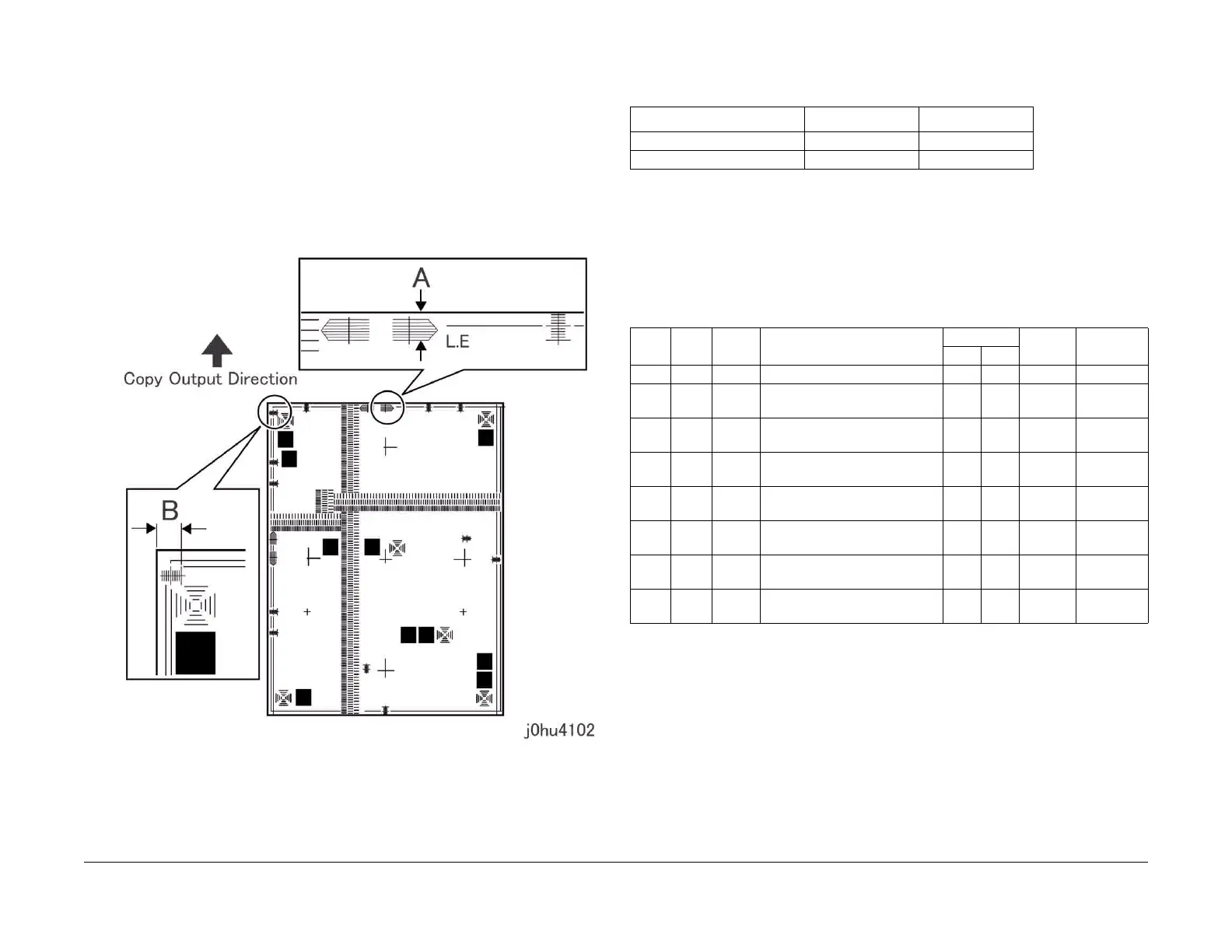

2. Measure the lead edge and side edge of the 3rd copy (Figure 1).

Lead edge: part A in the figure

Side edge: part B in the figure

Figure 1 IIT Lead Edge/Side Edge Registration

3. Check that the measured values for lead edge (A) and side edge (B) meet the specifica-

tions of the corresponding mode.

Adjustment

1. Enter the Diagnostic Mode, and use the following Chain Functions to perform adjustments

until the measured values for lead edge (A) and side edge (B) registration are within the

specifications.

When the measured value is short, reduce the setting value.

When the measured value is long, increase the setting value.

2. After the adjustment, again set the Test Pattern 499T247 (A3) on the platen so that there

is no gap between it and the Rear Registration Guide. Make a copy using 100% R/E and

A3 SEF paper.

3. Repeat the procedure until the measured values for lead edge (A) and side edge (B) are

within the specifications.

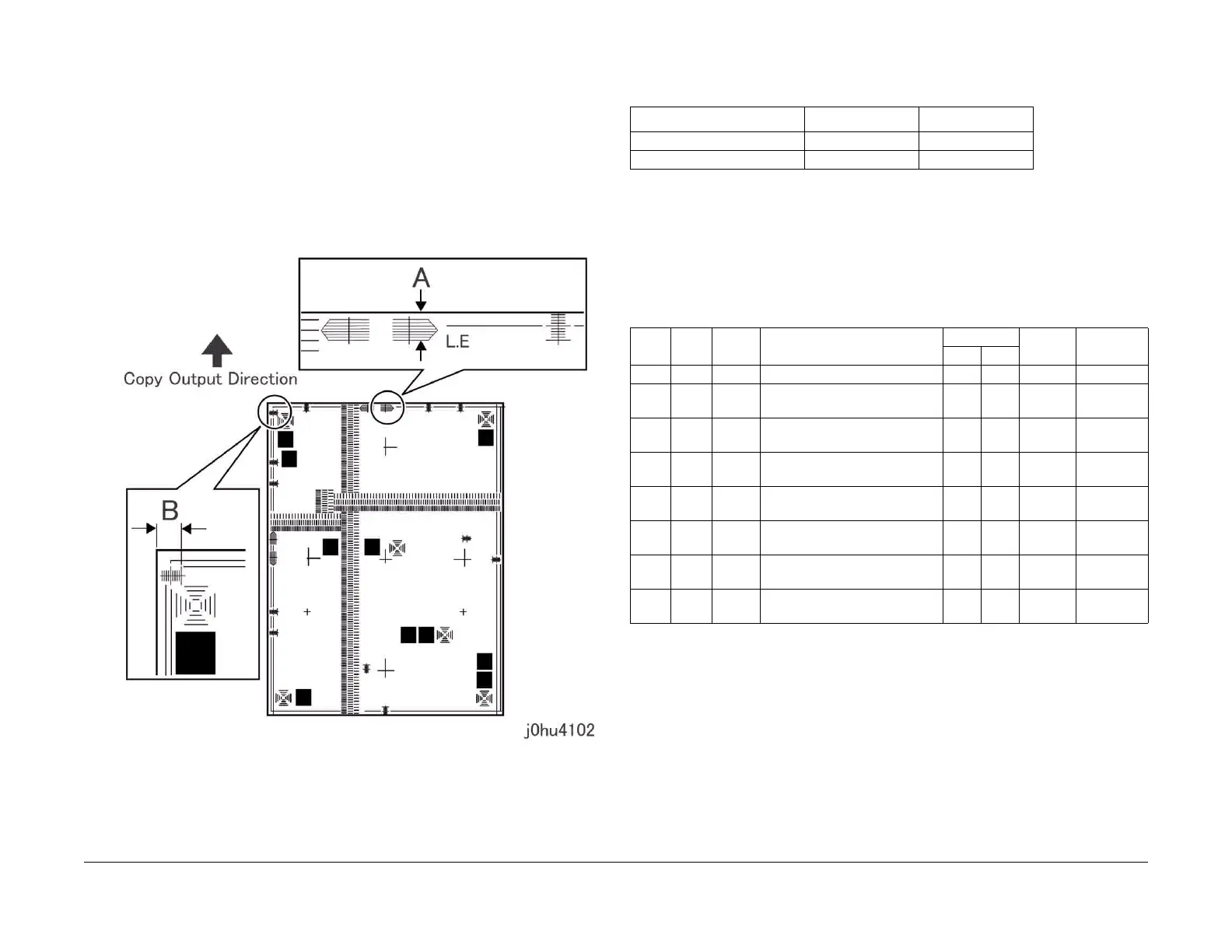

Table 1 Specification

Item Simplex MSI

Lead edge (A) 10 1.6mm 10 2.2mm

Side edge (B) 5 2.1mm 5 3.0mm

Table 2

Chain Func Sub

System

Name Value Initial

Value

1 Count

Min. Max.

20 1 PH REGI ADJUSTMENT - ALL 0 60 30 0.146mm

20 41 PH TRAY 1 for Normal LEAD REGI

ADJ

0 60 30 0.146mm

20 42 PH TRAY 2 for Normal LEAD REGI

ADJ

0 60 30 0.146mm

20 43 PH MSI for Normal LEAD REGI

ADJ

0 60 30 0.146mm

6 20 ROS ALL TRAY - LASER SIDE REGI

ADJUSTMENT

1 99 50 0.254mm

6 21 ROS TRAY 1 - LASER SIDE REGI

ADJUSTMENT

1 99 50 0.254mm

6 22 ROS TRAY 2 - LASER SIDE REGI

ADJUSTMENT

1 99 50 0.254mm

6 26 ROS MSI - LASER SIDE REGI

ADJUSTMENT

1 99 50 0.254mm

Loading...

Loading...