9.3

Absolute Position Detection for Finite Length Axes

9-9

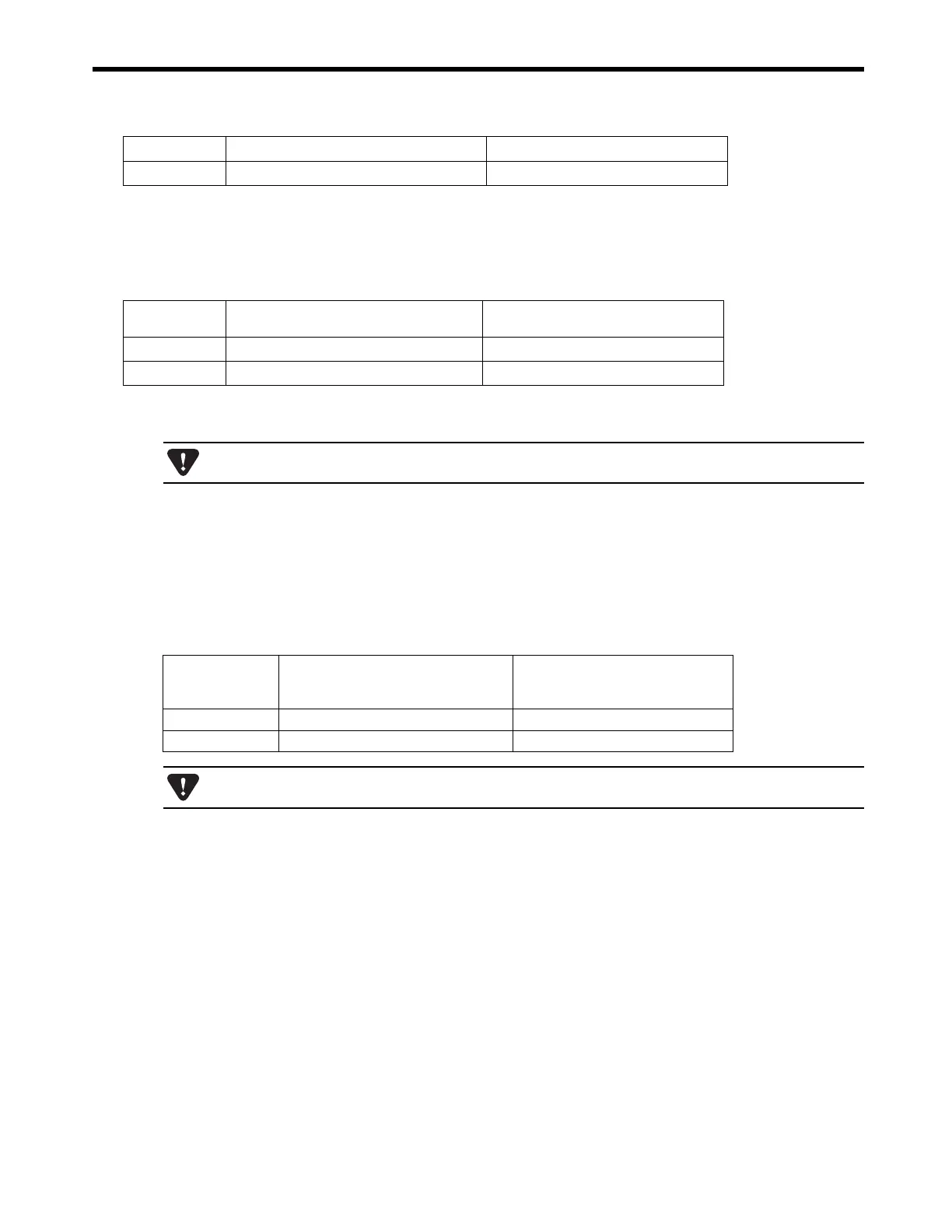

* 1. This value depends on the setting of Pn212 (PG dividing ratio). The values in the

table are the maximum values.

* 2. Because the maximum value of Pn201 (PG dividing ratio) is 16384, the maximum value

with a 17-bit encoder is also 16384.

• With SERVOPACKs in the

Σ

-III series

* This value depends on the setting of Pn212 (PG dividing ratio). The values in the table are

the maximum values.

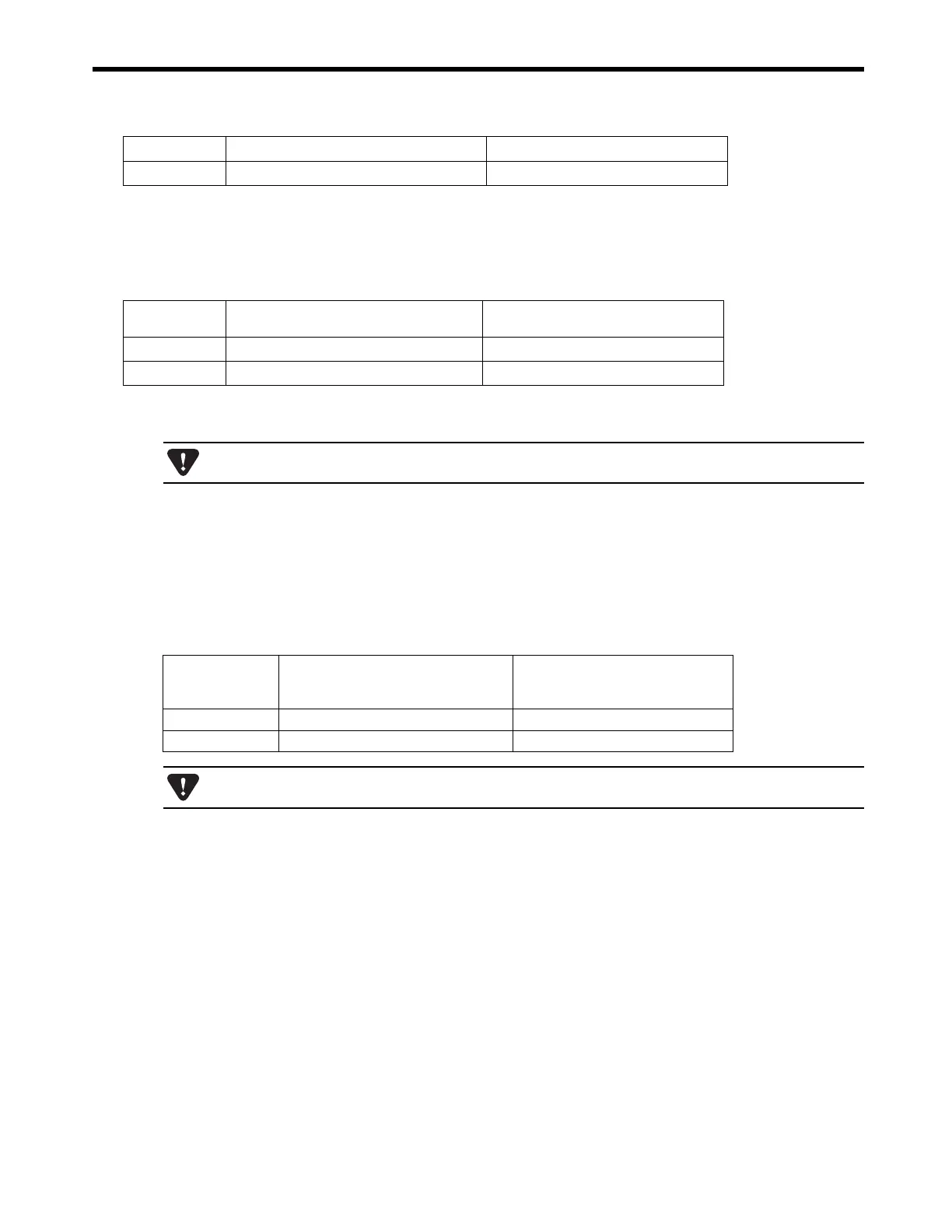

[ d ] Max. Revolution of Absolute Encoder/Multiturn Limit Setting

These parameters determine the maximum value of the number of encoder turns managed by the

SERVOPACK and MP2300.

The setting is determined by the SERVOPACK that is used and the type of axis (MP2300 fixed

parameter 1, bit 0). Set the parameters as shown in the following table when using an axis as a finite

length axis.

9.3.2 Setting the Zero Point for a Finite Length Axis

This section describes the procedure for setting the zero point (i.e., the absolute zero point or the zero

point of the machine coordinate system) for a finite length axis. It also describes the procedures for

storing the zero point offset.

16

16384

∗

1

6: Pulse A/B mode (

×

4)

17

16384

∗

1,

∗

2

6: Pulse A/B mode (

×

4)

Number of Bits

Fixed Parameter 36

(Encoder Resolution in Pulses/Resolution)

Fixed Parameter 22

(Pulse Counting Mode)

17

16384

∗

6: Pulse A/B mode (

×

4)

20

262144

∗

6: Pulse A/B mode (

×

4)

If the above settings are not used, correct motion control will not be performed. Set the parameters carefully.

Applicable

SERVOPACK

MP2300

Fixed Parameter 38

(Max. No. of Absolute Encoder Turns)

SERVOPACK

Parameter Pn205

(Multiturn Limit Setting)

Σ

-II,

Σ

-III Series

65535 65535

Σ-

I Series

99999

-

If the above settings are not used, the position may be offset. Set the parameters carefully.

Loading...

Loading...