SECTION 58 - ATTACHMENTS / HEADERS - CHAPTER 1

58-29

The backlash of the assembled disc module is

controlled by precision machining of the disc module

and top cap housings, the use of precision forged

gears, and the use of low tolerance bearings, which

are manufactured to provide a specific “stack height,”

or combined thickness. The backlash in the gear set

should be 0.13 -- 0.28 mm ( 0.005 -- 0.011 in) after the

module has been assembled.

If the back lash is found to be incorrect after gearbox

repair with new parts, recheck the module for correct

assembly of all components.

NOTE: Each bearing for the pinion shaft is

manufactured for a specific “stack height”. Do not mix

old and new bearing components or substitute with

“jobber” bearings.

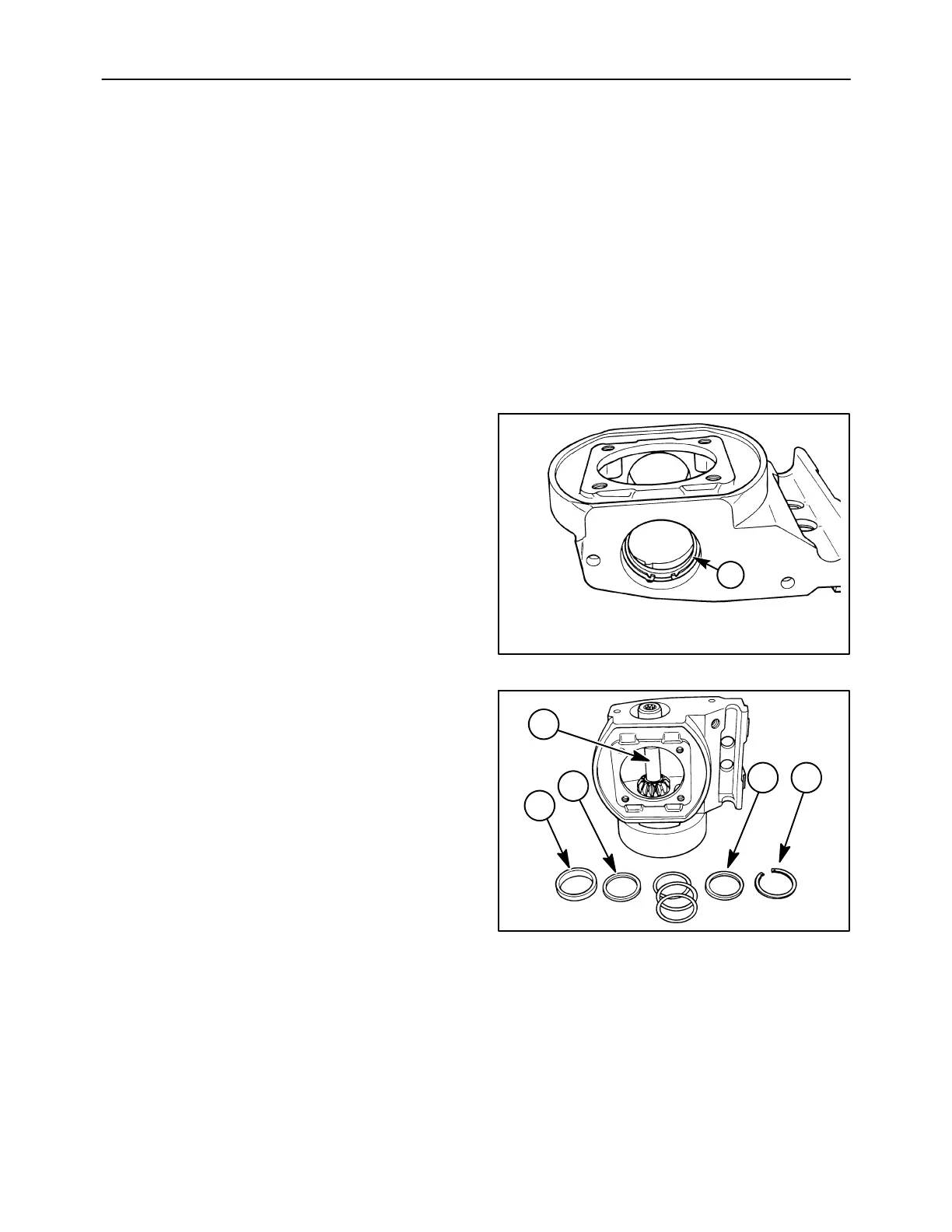

1. Install a snap ring, 1, on the pinion side of module

casting. Slide the bearing cup for the pinion side

bearing into the housing bore against snap ring.

Note that the direction of rotation desired will

affect which side of housing you start on. For

example, install snap ring on right side of housing

for clockwise rotation, and on the left side of

housing for counter-clockwise rotation.

A3654-11

1

66

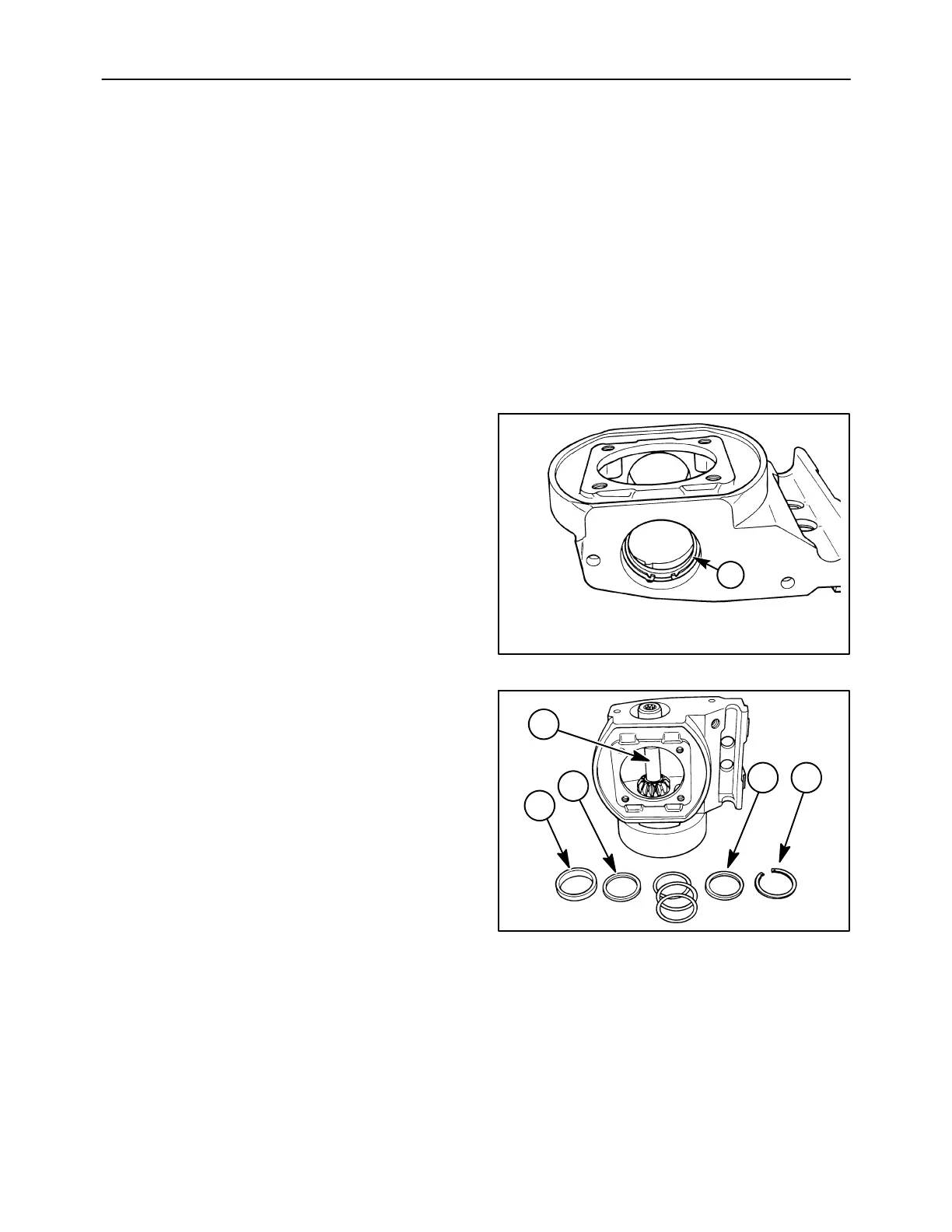

2. Support the module housing approximately 1/2

inch above the work surface on blocks, a large

piece of pipe as shown, or in an open vise;

position the snap ring and bearing cup down, 1.

Slide the assembled lower module shaft into

housing, making sure pinion side is down against

snap ring to orient properly for desired direction

of rotation.

3. Install the bearing cup, 2, that goes with the

upper bearing cone into the housing. Place the

two spacer washers, 3, on top of the bearing cup,

and install the snap ring, 4, into the groove in the

housing.

A3654-10

1

2

3

3 4

67

Loading...

Loading...