SECTION 58 - ATTACHMENTS / HEADERS - CHAPTER 2

58-9

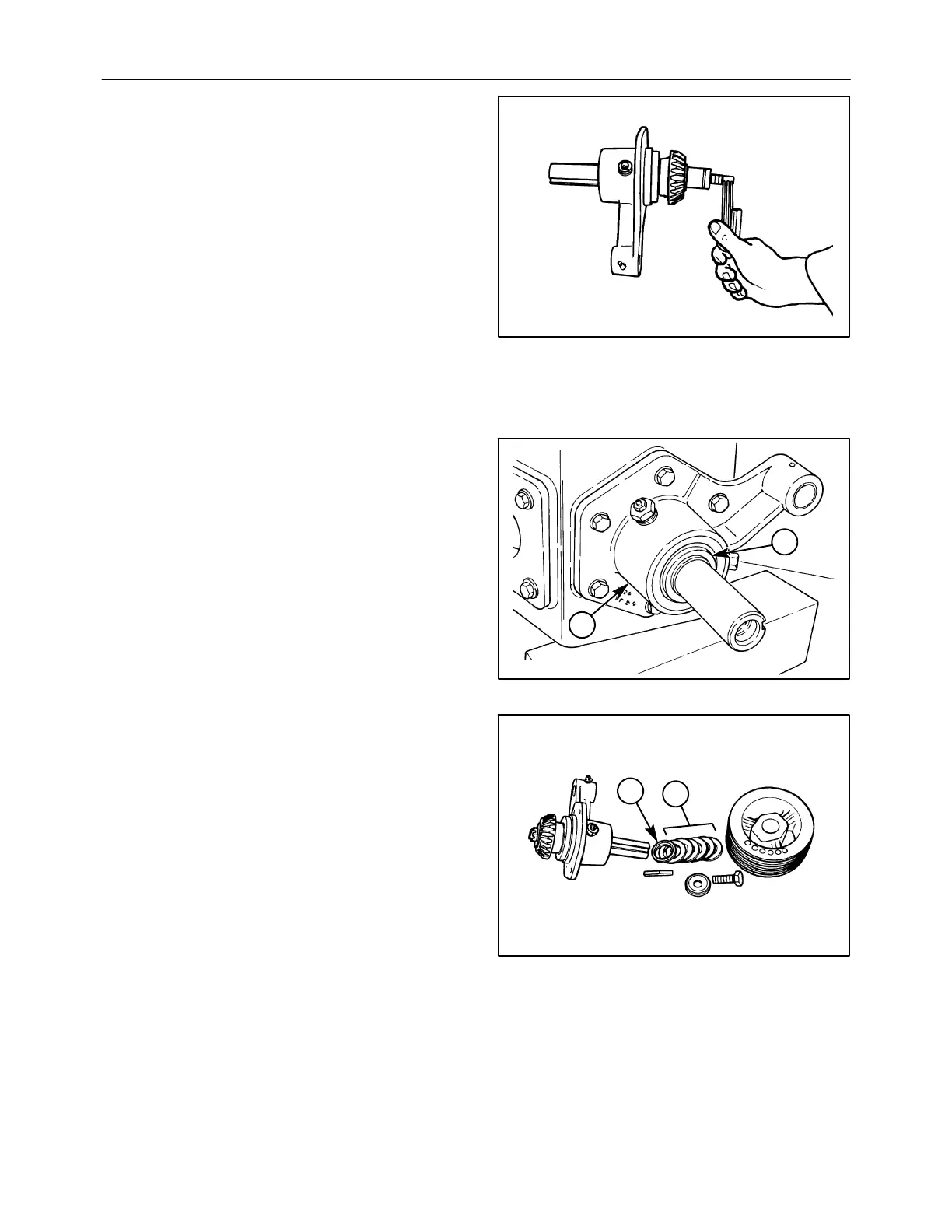

4. Install the flat washer and castellated nut onto the

shaft, and tighten the castellated nut as required

to obtain 0.23 -- 0.68 N⋅m (2 -- 6 in-lb) rolling

torque on the conditioner drive shaft assembly.

After adjusting the rolling torque, tighten or

loosen the nut as required in order to align it with

the hole in the shaft. If the nut must be rotated

more than one quarter of a flat to align it with the

hole, loosen off the nut, strike the shaft with a

soft-faced hammer to unseat the bearing cone,

and repeat the process. Recheck the rolling

torque prior to installing the cotter pin to ensure

it is correct.

IMPORTANT: Do not exceed 0.68 N

⋅

m(6in-lb)

rolling torque on the conditioner drive shaft

assembly, or bearing failure could occur.

1411/6-8

17

5. Lubricate the shaft seal lips liberally with grease,

and install the seal over the shaft and onto the

shoulder. Seat the seal, 1, into the housing, 2,

until it is flush with the outer face of the housing.

NOTE: The seal lip will engage on the shaft shoulder

at the same time the seal cage must be installed in

the housing bore; use caution to ensure the seal lip

does not roll outwards.

NOTE: Figure shows conditioner drive shaft

assembly installed on gearbox. Do not install

assembly until after input shaft rolling torque is

adjusted.

1411/6-16

1

2

18

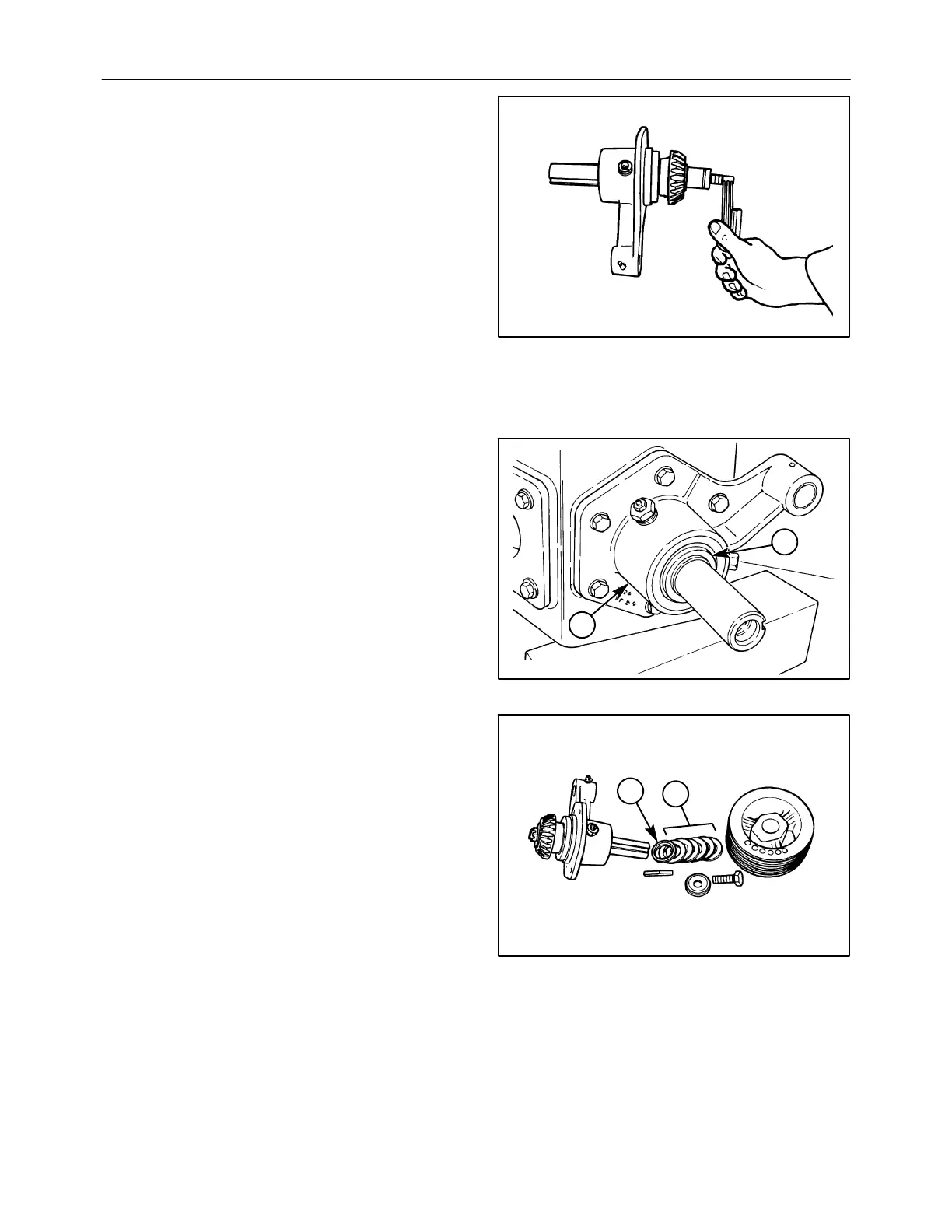

6. Install the spacer, 1, with the bevel facing in

towards the shoulder on the shaft. Slide on the

washers, 2, install the key in the keyway so that

the end is flush with the end of the shaft, slide on

the sheave, and install the cap screw and flat

washer.

NOTE: It will be easier to torque the sheave retaining

bolt after installing the bevel gearbox back onto the

unit.

1411/6-2

2

1

19

Loading...

Loading...