SECTION 58 - ATTACHMENTS / HEADERS - CHAPTER 2

58-10

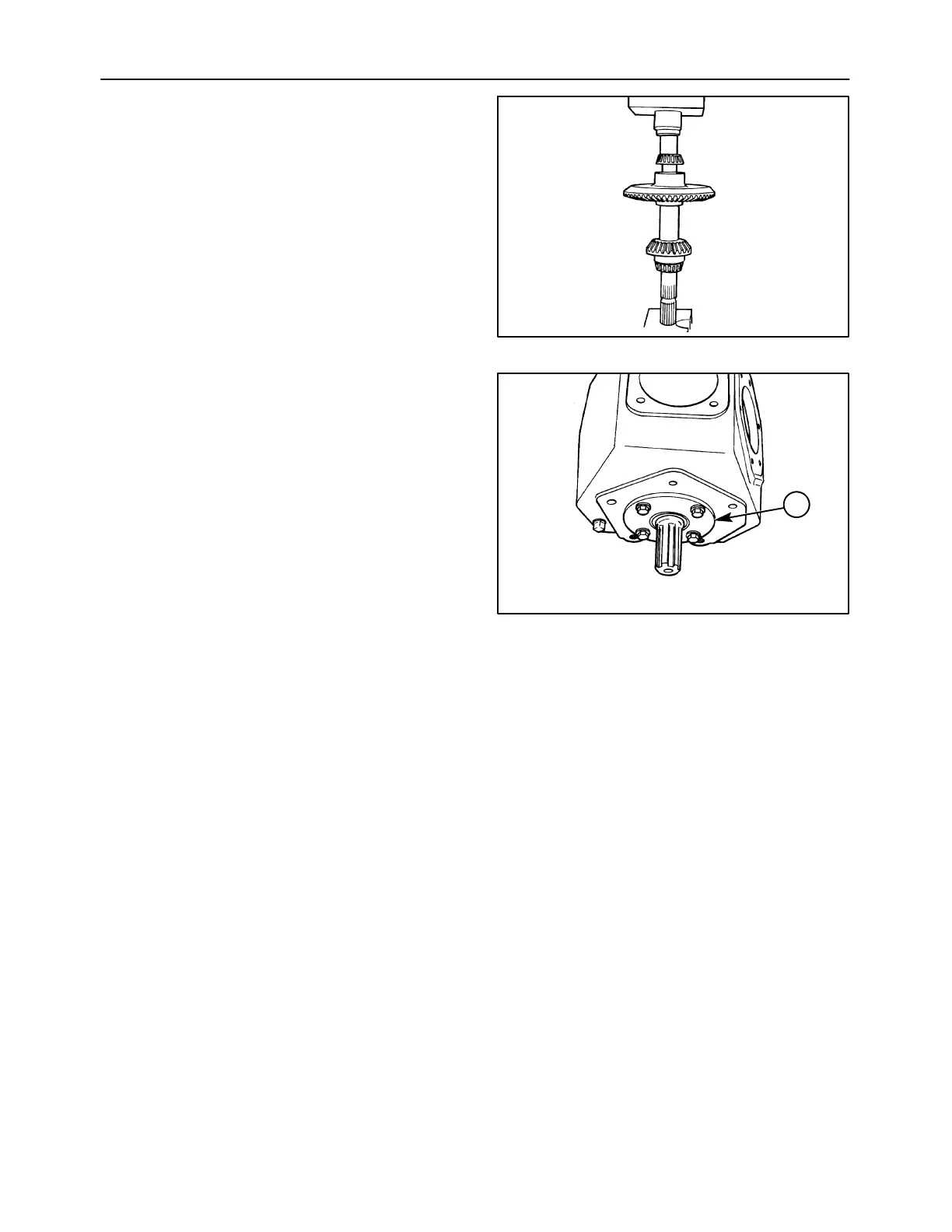

7. Install a 24T gear onto the front of the input shaft,

and press a bearing cone onto shaft until it seats

against shoulder on shaft. Install the 54T gear

onto the end of the shaft and press a bearing

cone onto shaft until the gear seats against the

collar on the shaft. Press bearing cones onto the

output shaft.

8. Install new bearing cups into the input shaft

bearing caps and gearbox housing. Do not install

shaft seals into the input and output shaft bearing

caps at this time.

1411/6-9

20

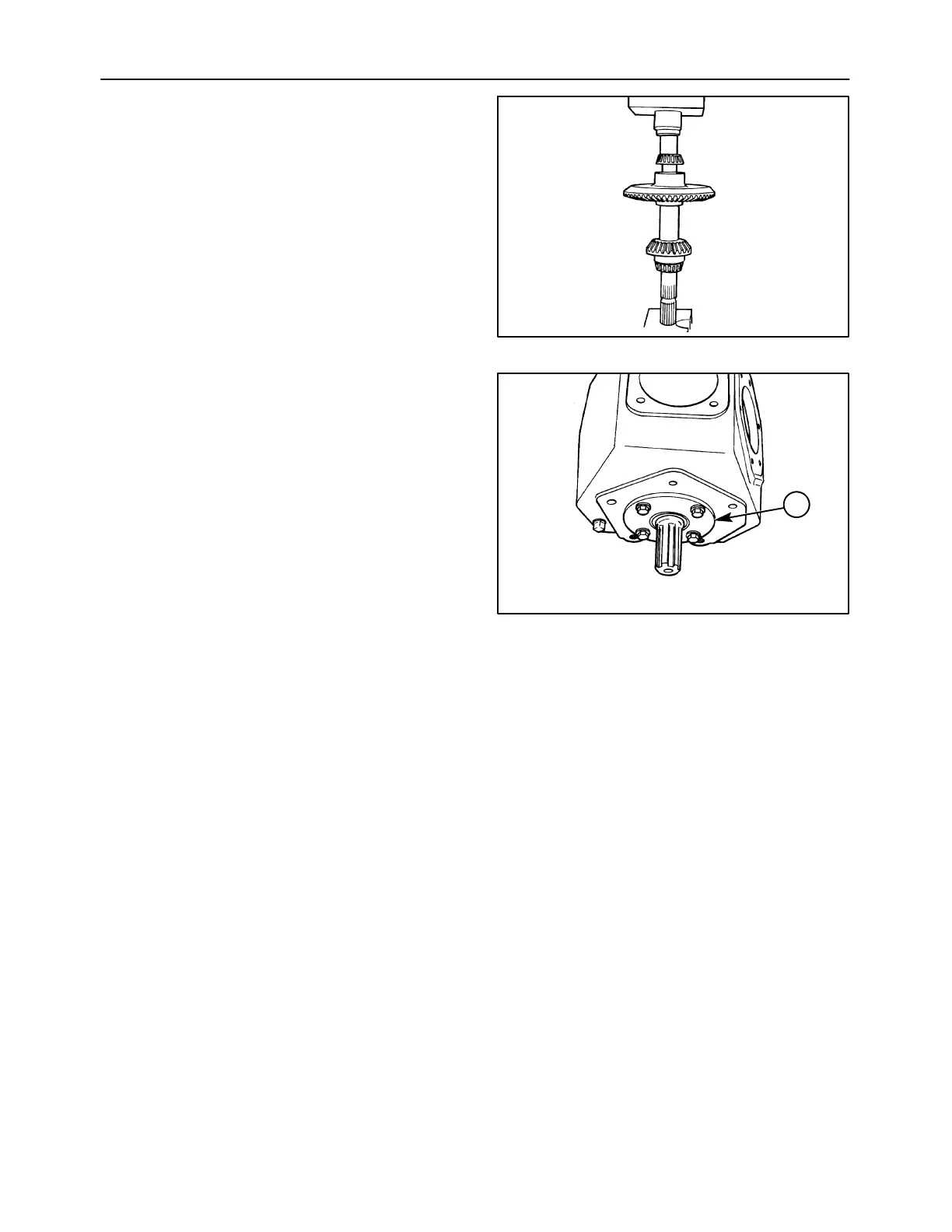

9. Apply oil to the output shaft bearing cones, and

position the output shaft assembly into the

gearbox housing; install a new bearing cup to

retain shaft. Install the bearing cap, 1, and the

original shim pack using four cap screws and lock

washers. If the original shim pack is destroyed,

or if all new parts are being used, use a starting

shim pack thickness of 0.38 mm (0.015 in).

Check and adjust the output shaft rolling torque

to 0.23 -- 0.68 N⋅m (2 -- 6 in-lb) by shimming under

the bearing cap as required. If the output shaft

rolling torque is initially too tight, tap the shaft

downwards to remove the preload on the

bearings before reinstalling the bearing cap and

revised shim pack.

NOTE: The output shaft rolling torque can be

checked by selecting a socket which fits over the

shaft, and lock it to the shaft by sliding a hex key

wrench between the shaft spline and socket. Attach

an inch-pound torque wrench to socket.

NOTE: Do not install the shaft seal or anti-wrap

shield on the bearing cap prior to checking and

adjusting the rolling torque.

1411/6-4

1

21

Loading...

Loading...