SECTION 58 - ATTACHMENTS / HEADERS - CHAPTER 2

58-11

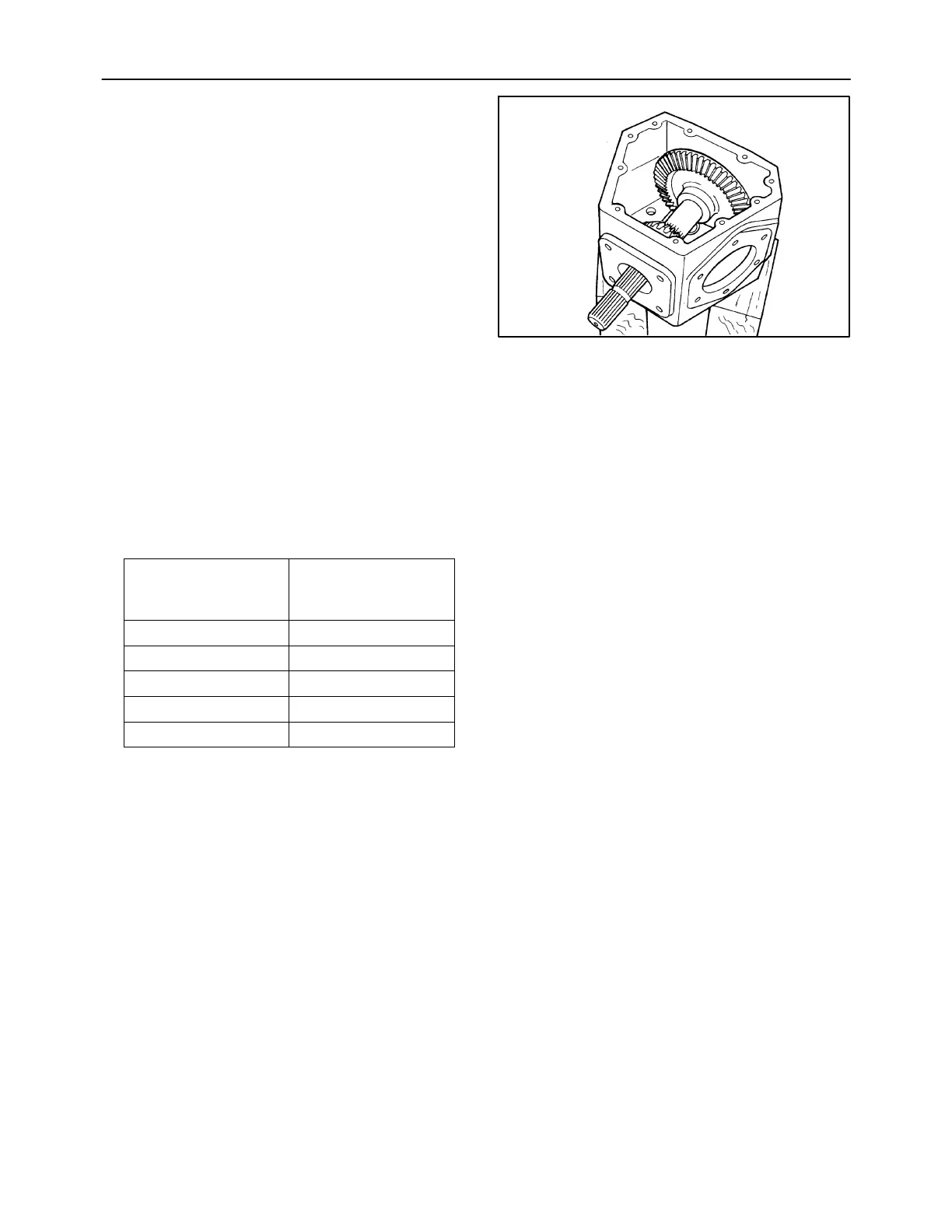

10. Apply oil to the input shaft bearing cones, and

install the input shaft assembly into the housing

by inserting the input end through the front

opening in housing until the 54T gear can be

lowered into the housing.

Apply a thin bead of silicone sealant to the

shoulder on the rear bearing cap, and install it

using four cap screws and lock washers. Apply

silicone sealant to the cap screw threads to seal

them to the housing.

Install the front bearing cap and the original shim

pack using four cap screws and lock washers; do

not apply silicone sealant until after shimming is

completed. If the original shim pack is destroyed,

or if all new parts are being used, use a starting

shim pack thickness of 0.64 -- 0.76 mm (0.025 --

0.030 in).

Install a 1/2″ x3/4″ cap screw into the front of the

input shaft and use a socket and inch-pound

torque wrench to check the input shaft rolling

torque. Adjust the input shaft rolling torque by

adding or removing shims under the bearing cap

to obtain the appropriate rolling torque per the

following chart:

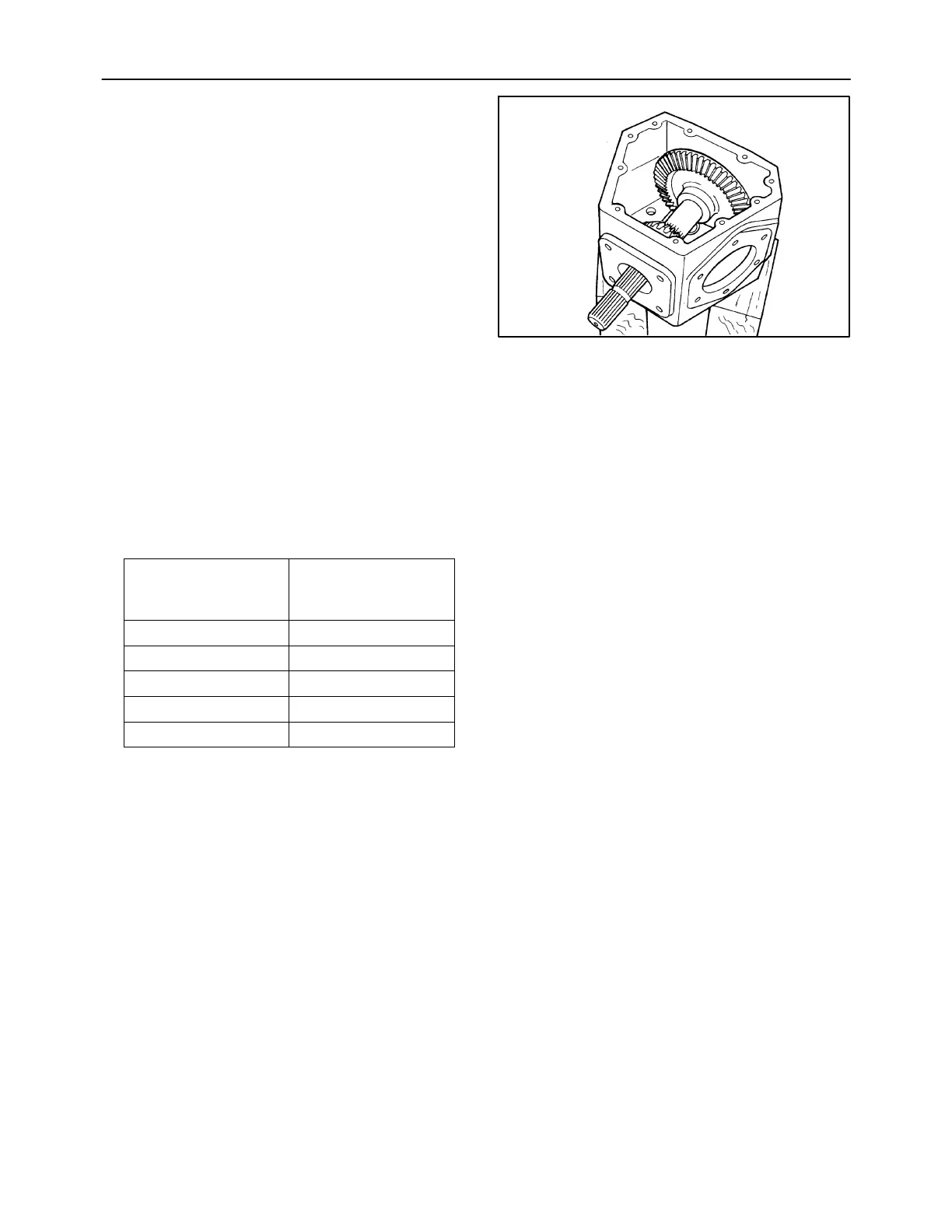

Output Shaft

Input Shaft

o

ng

orque

N⋅m(in-lb)

o

ng

orque

N⋅m(in-lb)

0.23 (2) 0.9 -- 1.36 (8 -- 12)

0.34 (3) 1.24 -- 1.7 (11 -- 15)

0.45 (4) 1.58 -- 2 (14 -- 18)

0.57 (5) 1.9 -- 2.4 (17 -- 21)

0.68 (6) 2.26 -- 2.7 (20 -- 24)

NOTE: Rolling torques shown are without shaft seals

installed. Do not install shaft seals until after rolling

torques are adjusted.

11. After obtaining the correct rolling torque on the

input shaft, remove the front bearing cap and

apply a thin bead of silicone sealant to the

shoulder to seal the cap to the housing. Apply a

small amount of silicone sealant to the end of

each retaining bolt to seal it to the housing also.

1411/6-10

22

Loading...

Loading...