SECTION 58 - ATTACHMENTS / HEADERS - CHAPTER 3

58-17

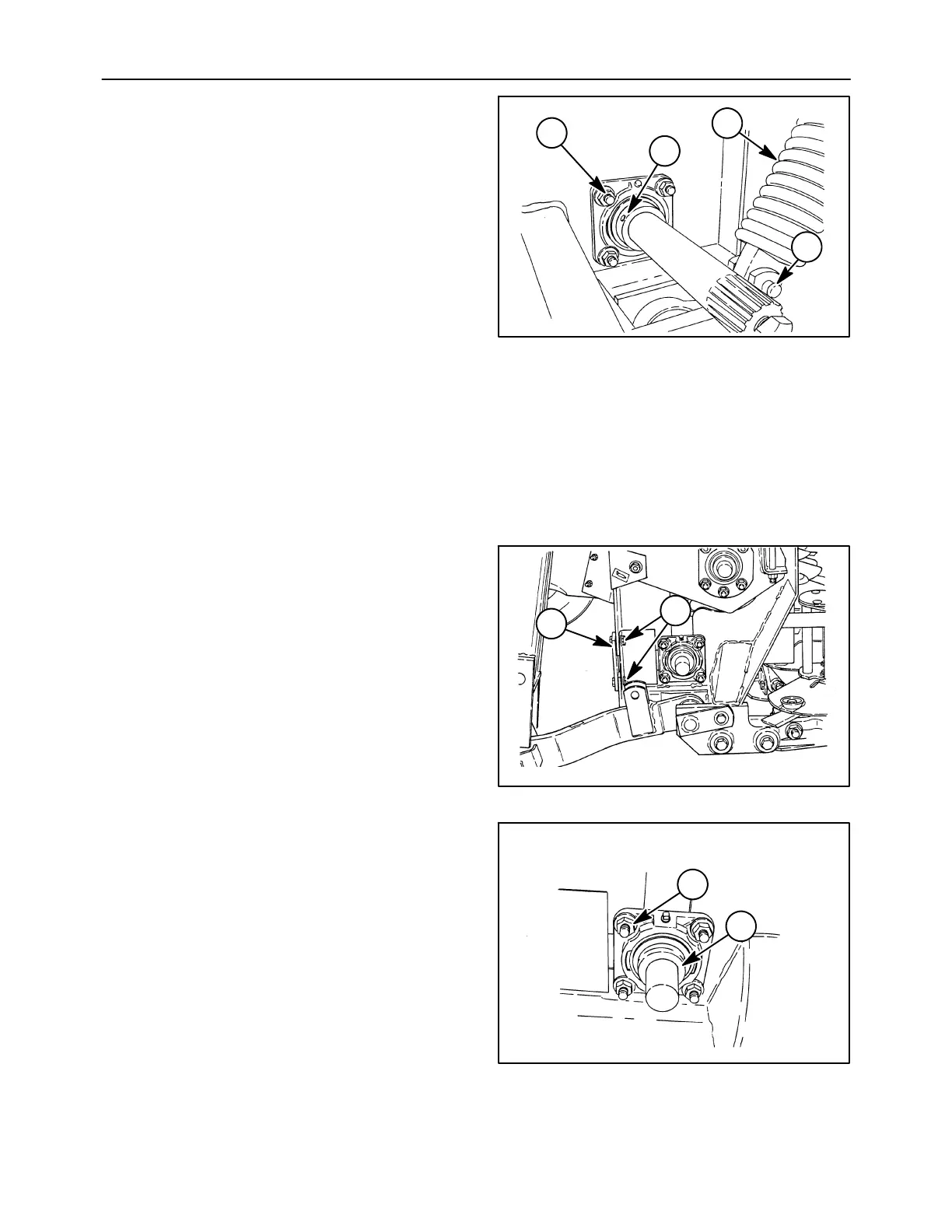

9. Clean the shaft thoroughly using emery cloth.

Loosen the setscrew, 1, and remove the lock

collar by driving it in the opposite direction of

rotation using a hammer and punch. Use a file to

remove any marks on the shaft from the lock

collar setscrew.

Support the left end of the conditioner roll using

a suitable lift, floor jack or blocking. Remove the

four flange nuts, 2, and slide the bearing and

housing off the lower conditioner roll shaft.

NOTE: Shaft preparation is very important when

removing the locking collar and bearing. Clean it

thoroughly with emery cloth and lubricate it to ease

bearing removal.

10. Loosen the adjusting bolt to relieve all tension on

the right side flotation spring. Remove the cotter

pin and slide the clevis pin, 3, out of the brackets

on the lift arm. Allow the flotation spring, 4, to lay

back against the right side tire.

NOTE: Removing the flotation spring will provide

improved access to the right side of the lower

conditioner roll to ease removal.

19992642

1

2

3

4

42

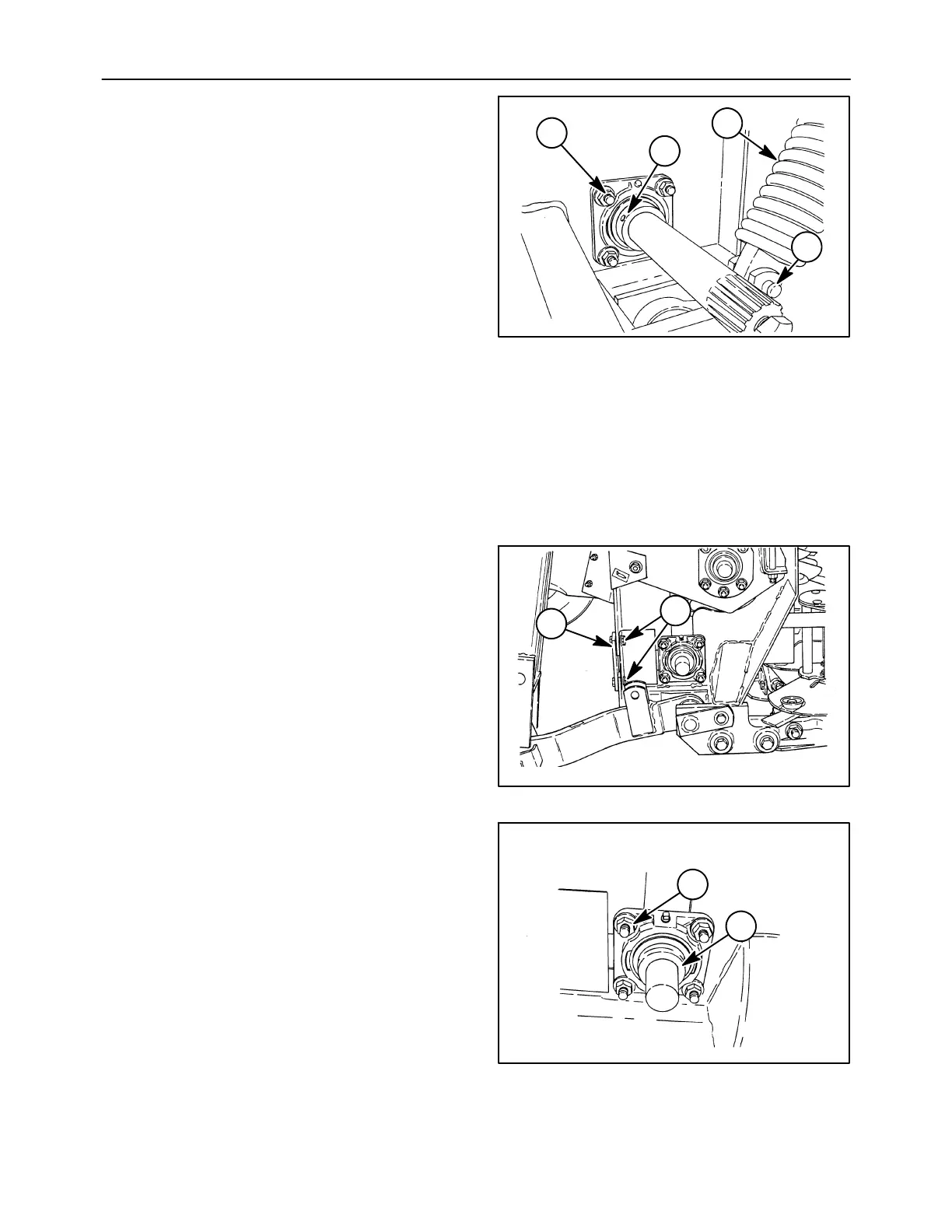

11. Remove the plates, 1, on the removal slot at the

right side of header by removing the two cap

screws, 2.

A5049-4

1

2

43

12. Loosen the setscrew and remove the lock collar,

1, by driving it in the opposite direction of rotation

using a hammer and punch.

13. Clean any rust, dirt or corrosion off the shaft

using emery cloth, and file down any marks from

the locking collar setscrew. Support the lower

conditioner roll using a suitable lift, floor jack, or

appropriate blocking. Remove the four flange

nuts, 2, and slide the bearing and housing off the

shaft. Note that the top rear bolt on the right side

of the header is loose (not welded to header) and

should also be removed.

NOTE: Removing the top rear bolt on the right side

of the header eases removal of the upper roll pivot

arm.

19992643

1

2

44

Loading...

Loading...