45 of 165

M-SV-VT-001-EN Rev. A

Compressor Components

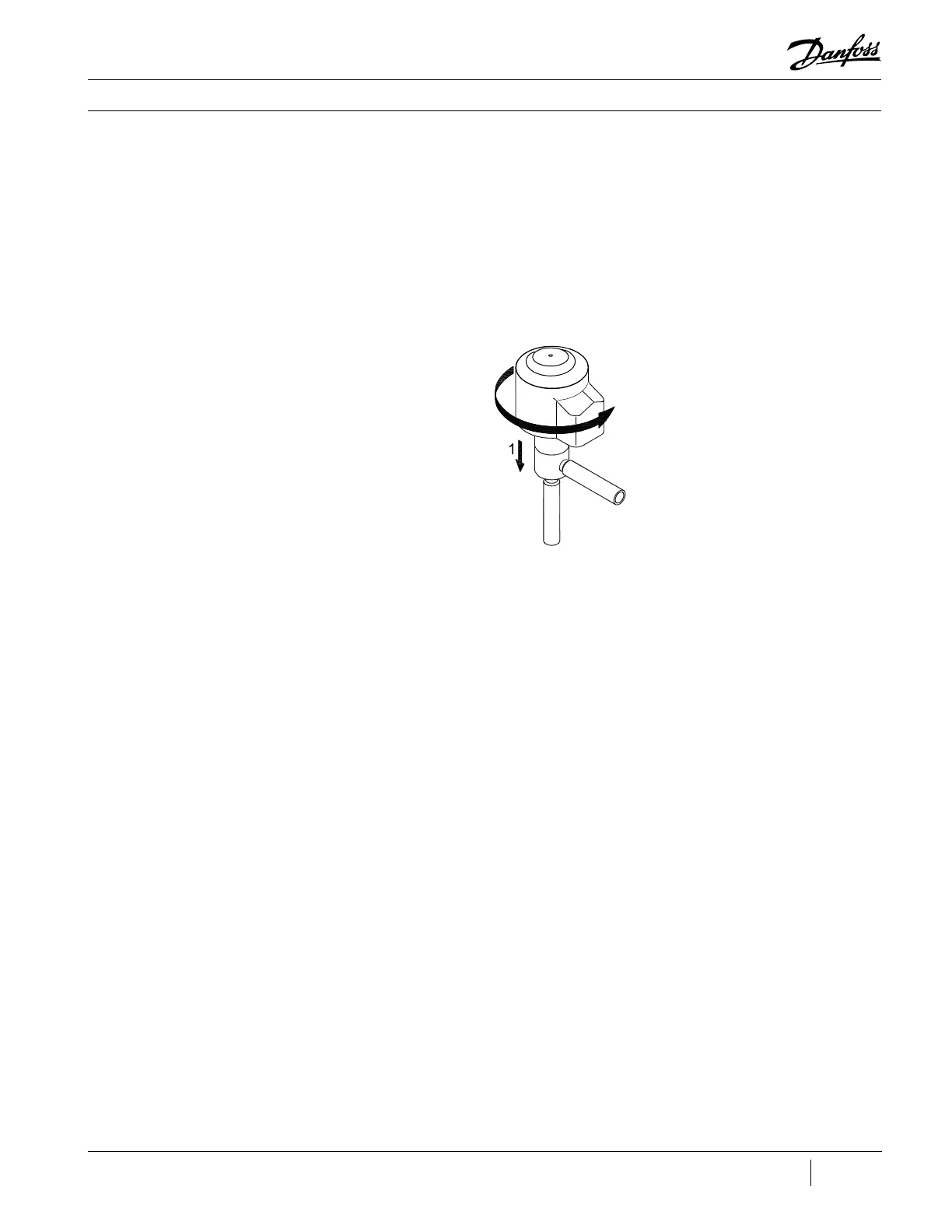

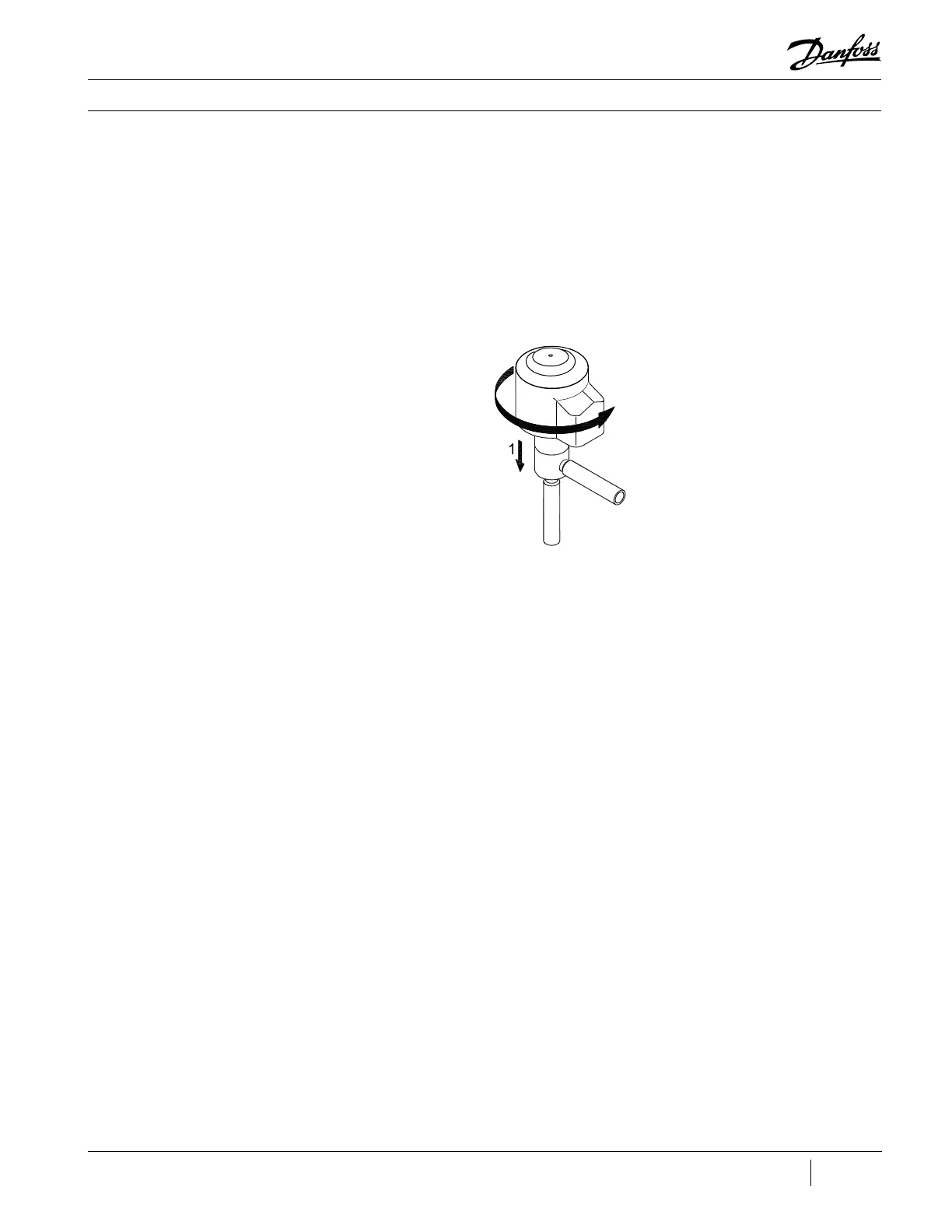

Figure 37 - Opening Valve

Manually

2

3.2.7.3 EXV Protection The following steps, when performed properly, will help ensure that the EXV is not damaged when

brazing the copper line to the valve.

1. Ensure the actuator coil has been removed from the EXV.

2. The new valve should be shipped in the open position but to ensure that the valve is completely

open, use ETS 6 manual coil part number 034G5119 (purchase through local Danfoss supplier)

and manually open the valve by turning the manual coil 20 times in the counter-clockwise

rotation. (If an ETS 6 manual coil is not available, the actuator coil can be used if the retaining

clip is removed so that it can spin freely on the valve stem. If using the power head, take special

care to protect the electrical wires extending from the actuator coil.)

3. Remove the ETS6 manual coil or actuator coil.

4. Wrap the valve in cool wet towels to help prevent excessive heat from damaging the valve.

5. Using a MAPP and AIR mixture torch, NOT MAPP gas and oxygen, nor an Oxy Acetylene torch,

heat the shipping cap on the stub end of the valve until the solder becomes liqueed. While the

solder is still liqueed, carefully remove the cap with pliers.

6. Clean the now open copper tube with a sanding cloth and then apply soldering ux to the

exterior of the clean copper tube. Do the same to the mating copper pipe that will connect from

the system to the motor cooling valve.

7. Slide the system-side pipe over the stub of the EXV ensuring a minimum of a 9.5 mm (3/8”)

connecting joint.

8. Make sure the towels around the motor cooling valve are still cool and wet, re-wet and re-wrap

if needed.

9. Using a MAPP and AIR mixture torch, heat the two (2) sections of pipe and apply a (6% silver

94% tin) type solder ensuring the two (2) pipe connections are properly sealed.

10. Leak test the cooled joint to ensure leak tightness.

Loading...

Loading...