150

FUEL SYSTEM

FUEL COMPONENT SERVICING

Disassembly

All reed pla te assemb ly an d reed va lve assem-

blies must be clea ned prior to rea ssembly. DO

NOT use strong ca rburetor cleane r or the hot

soaking tank method for cleaning.

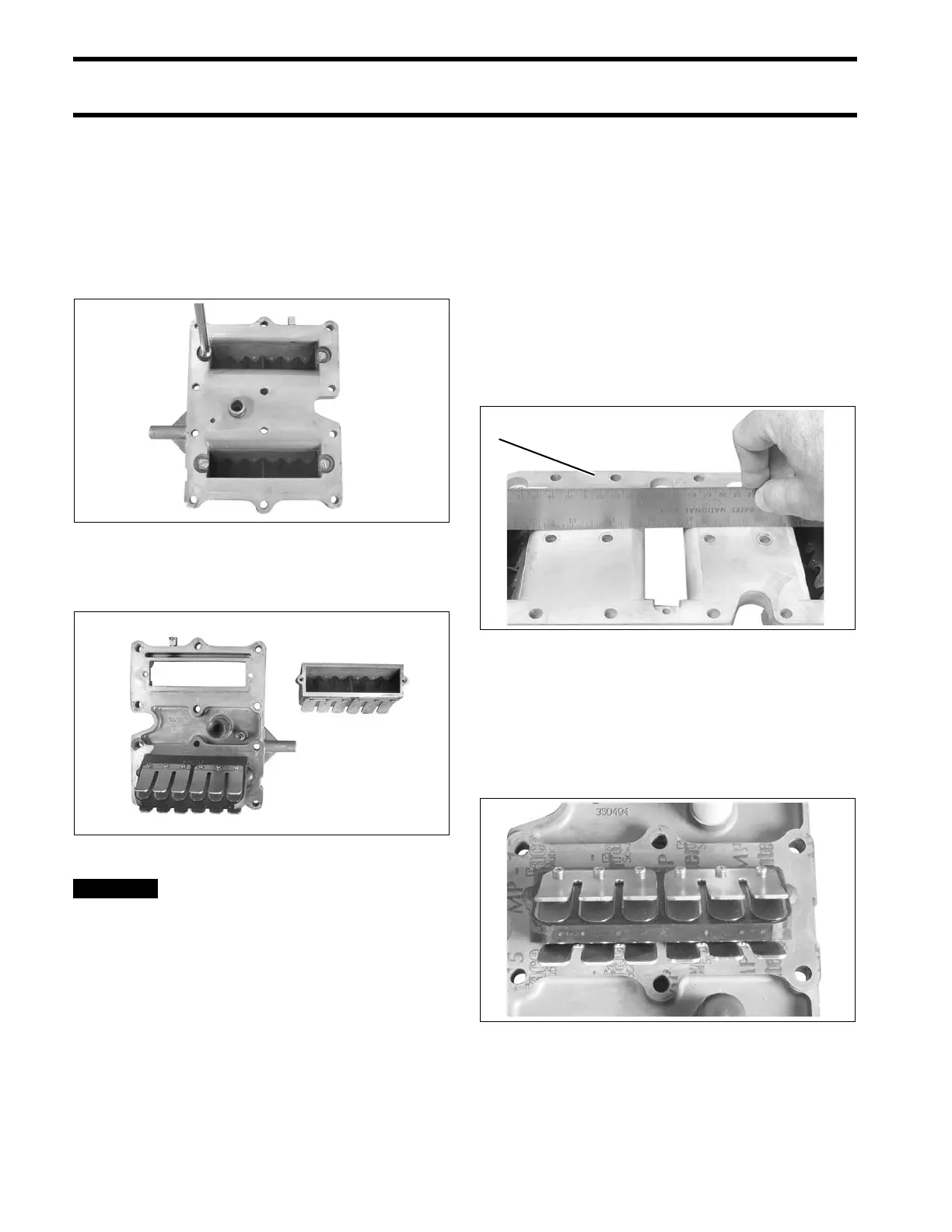

Remove the re ed valve ret ainer screws a nd

remove the assembly.

Use cau tion to prevent damaging reed valve

assemblies.

DO NOT disassemble reed valve

assemblies. Damaged reed plates are not ser-

viceable and are replaced as an assembly.

Inspection

Inspect the leaf plate a ssemblies for da mage or

contamination:

• Leaf plates must not be distorted.

• Leaf valve must not be cracked or chipped.

• Leaf plate stops must not be distorted or loose.

• Leaf plate assemblies must be clean.

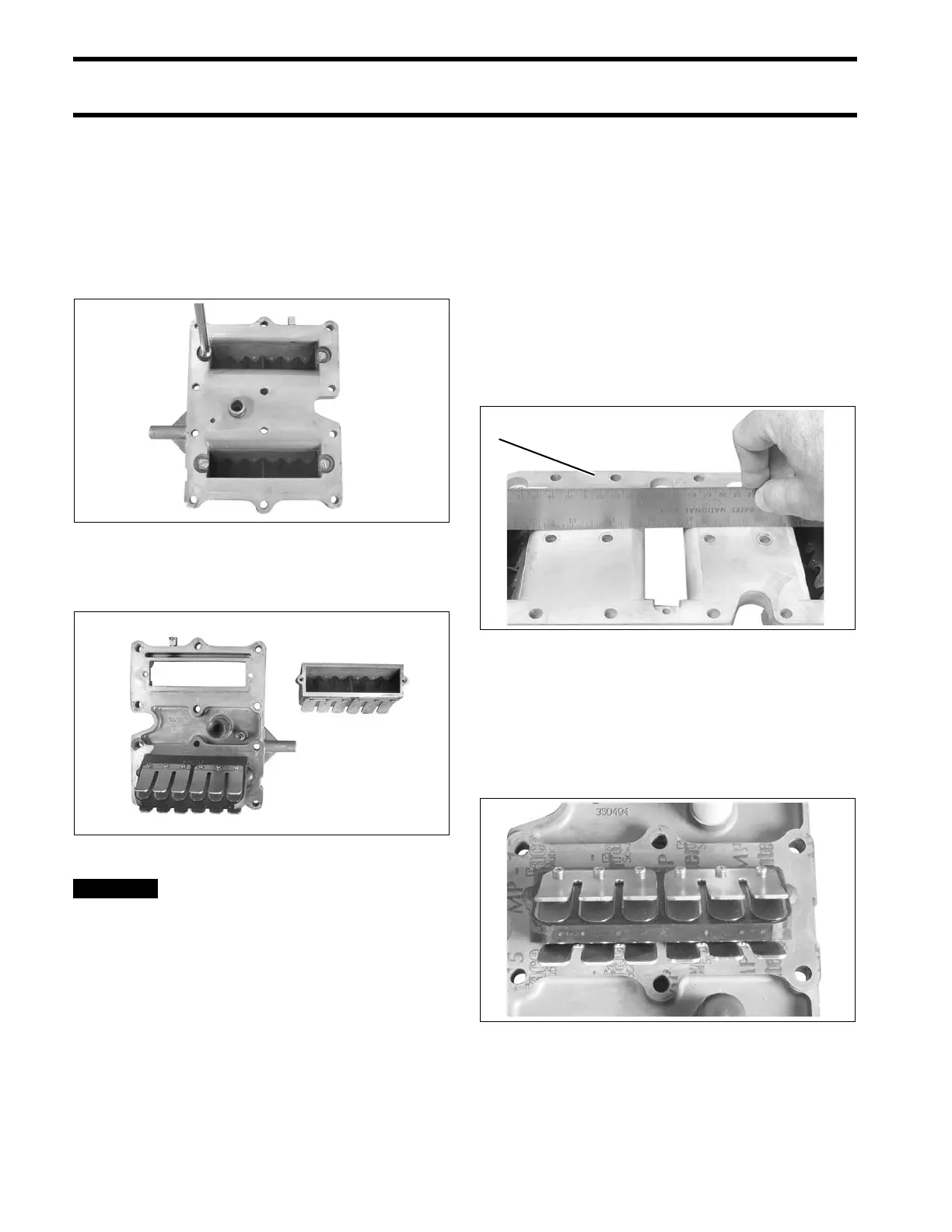

Inspect t he intake manifold. All gasket surfaces

must be cleaned, smooth, and free of nicks. Use a

machinist’s stra ight-edge and a feeler gauge to

check flatness in all directions. Surface must be

flat, ± 0.004 in. (0.10 mm).

Assembly

Remove old adhe sive from reed valve ret aining

screws.

Install ga sket on reed plate assembly . DO NOT

use sealer on the gasket.

002496

002504

1. Straight-edge 002324

002333

Loading...

Loading...