151

FUEL SYSTEM

FUEL COMPONENT SERVICING

7

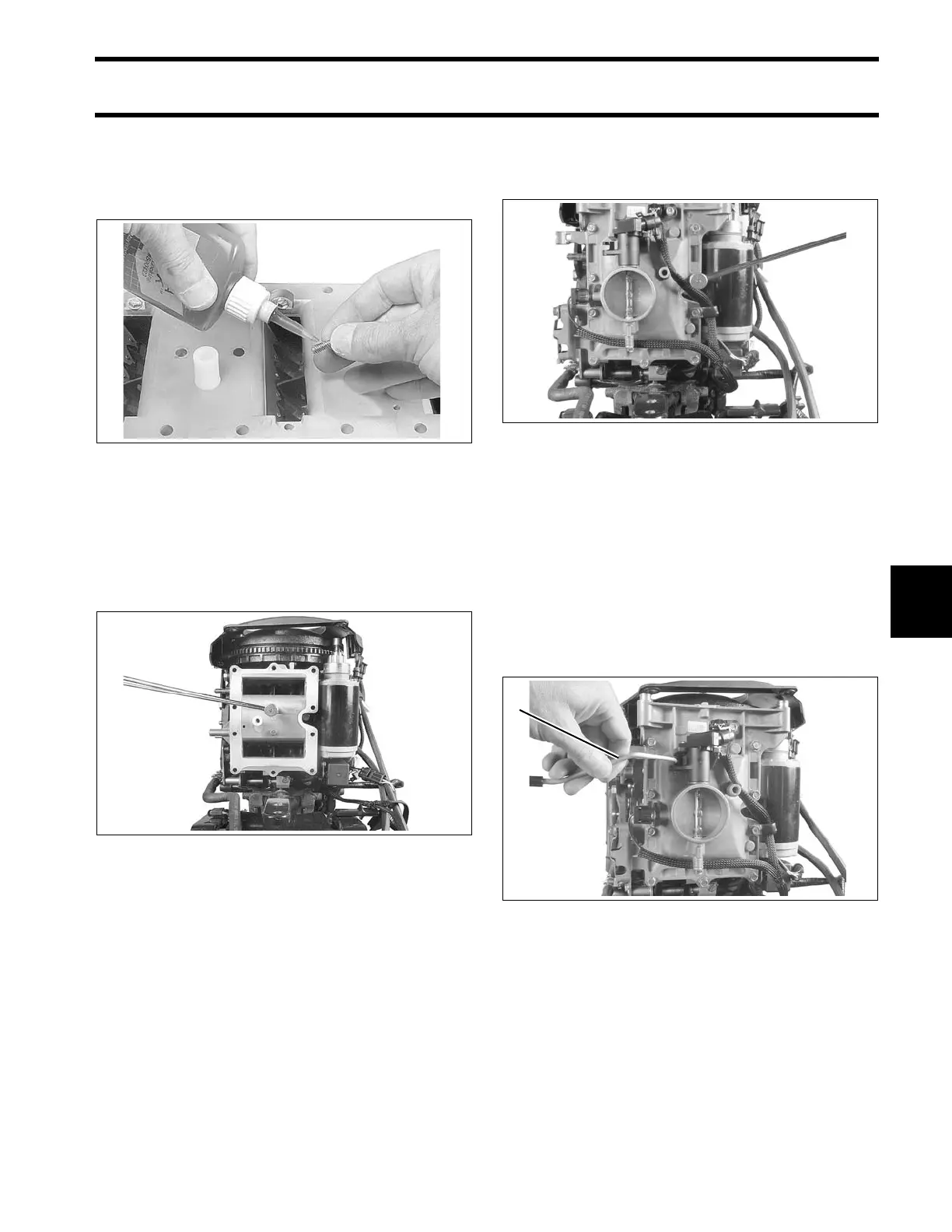

Prime screw th reads with Locquic Primer and let

dry. Apply Nut Lock to threads. Position reed valve

on reed plate an d install screws. T ighten screws

to a torque of 25 to 35 in. lbs. (2.8 to 4.0 N·m).

Installation

Place reed plate assembly on cylinder/crankcase.

Apply Nut Lock to two re ed plate screws. Inst all

and tighten screws to a torque of 60 to 120 in. lbs.

(7 to 13.5 N·m).

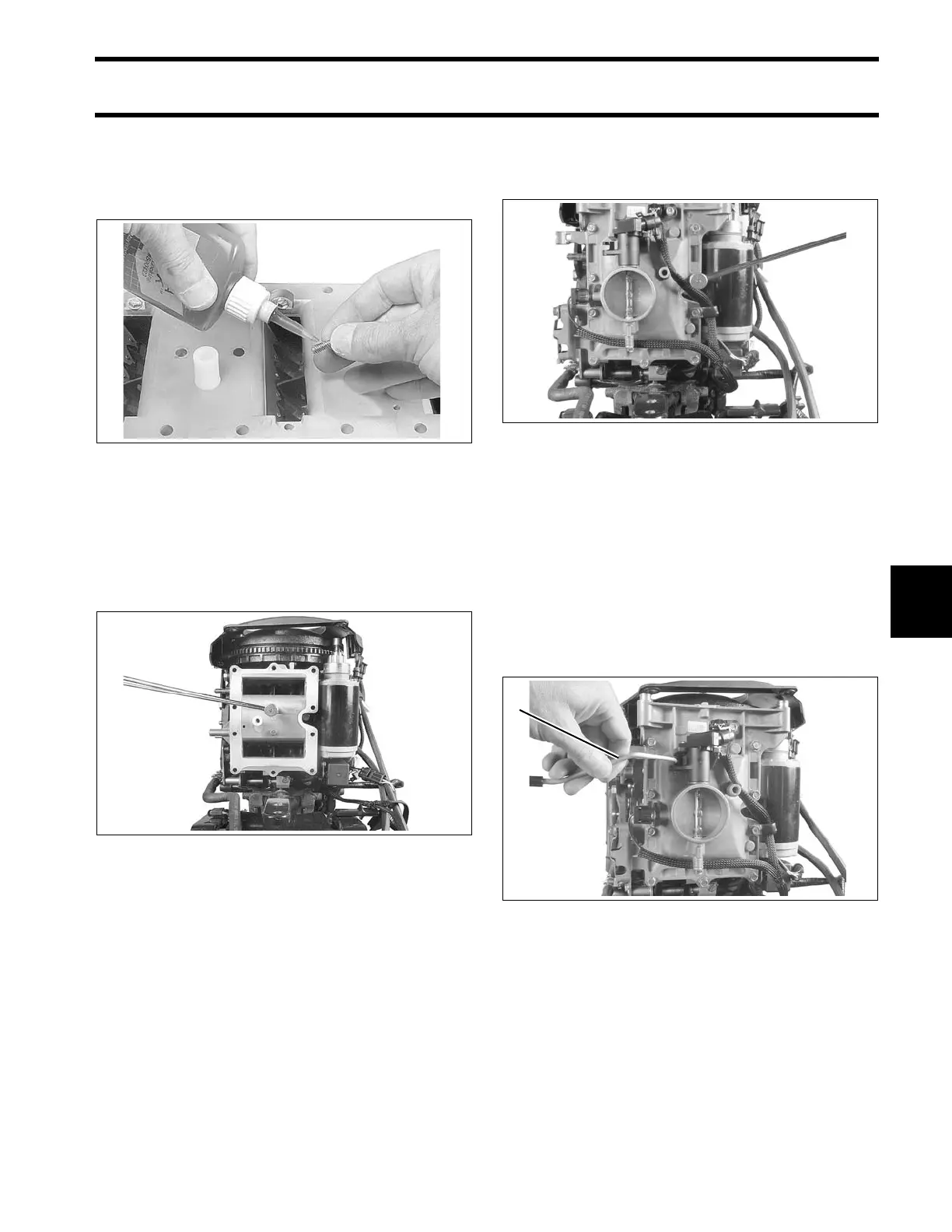

Place gasket on thro ttle body. Install throttle body

on reed plate and install new screws.

IMPORTANT: If old screws mu st be re-used,

make sure all previous thread locking mate rial is

removed and apply Nut Lock to threads.

Tighten the center screws first and exp and o ut-

ward. Tighten in st ages to a final to rque of 60 to

120 in. lbs. (7 to 13.5 N·m).

Install vapor separator vent hose and main bear-

ing vent hose. Secure with tie straps.

Install air temp erature sensor, crankshaft position

sensor, and throttle position sensor electrical con-

nectors.

Connect throttle linkage.

IMPORTANT: DO NOT lubricate th rottle link-

ages.

Refer to TPS Calibration on p. 114.

002326

002505

002501

1. Throttle linkage 002500

Loading...

Loading...