306

GEARCASE SERVICE, 40 – 65 HP MODELS

SHIFTER, BEARING AND SEAL SERVICE

Place the bearing on the installer tool with the let-

tered side of the bearing facing the top of the

gearcase. Use Needle Bearing grease to hold the

bearing on the tool.

Insert the to ol with the be aring into the gea rcase.

Drive the bearing into the gearcase until the

washer on the tool contacts the spacer.

Place a new O-ring on the pinion bearing retaining

screw. Apply Gasket Sealing Compound to O-ring

and Nut Lock to screw threads. I nstall th e screw

and tighten to a torque of 48 to 80 in. lbs. (5.5 to

9.0 N·m).

Shift Housing Disassembly

IMPORTANT: The shif t h ousing and forward

gear bea ring are serviced as an asse mbly. If

either are worn or damaged, replace the complete

assembly.

Insert a suitable tool under one end o f the clutch

dog spring and remo ve it from its groove by

unwrapping it from aro und the clut ch dog. Dis-

card the spring.

Push the p in o ut of th e clutch dog. Remove all

parts.

Remove the ge ar, thrust bearing, and thrust

washer from the shift housing.

1. Bearing retaining screw 001997

A WARNING

Wear safety glasses to avoid injury.

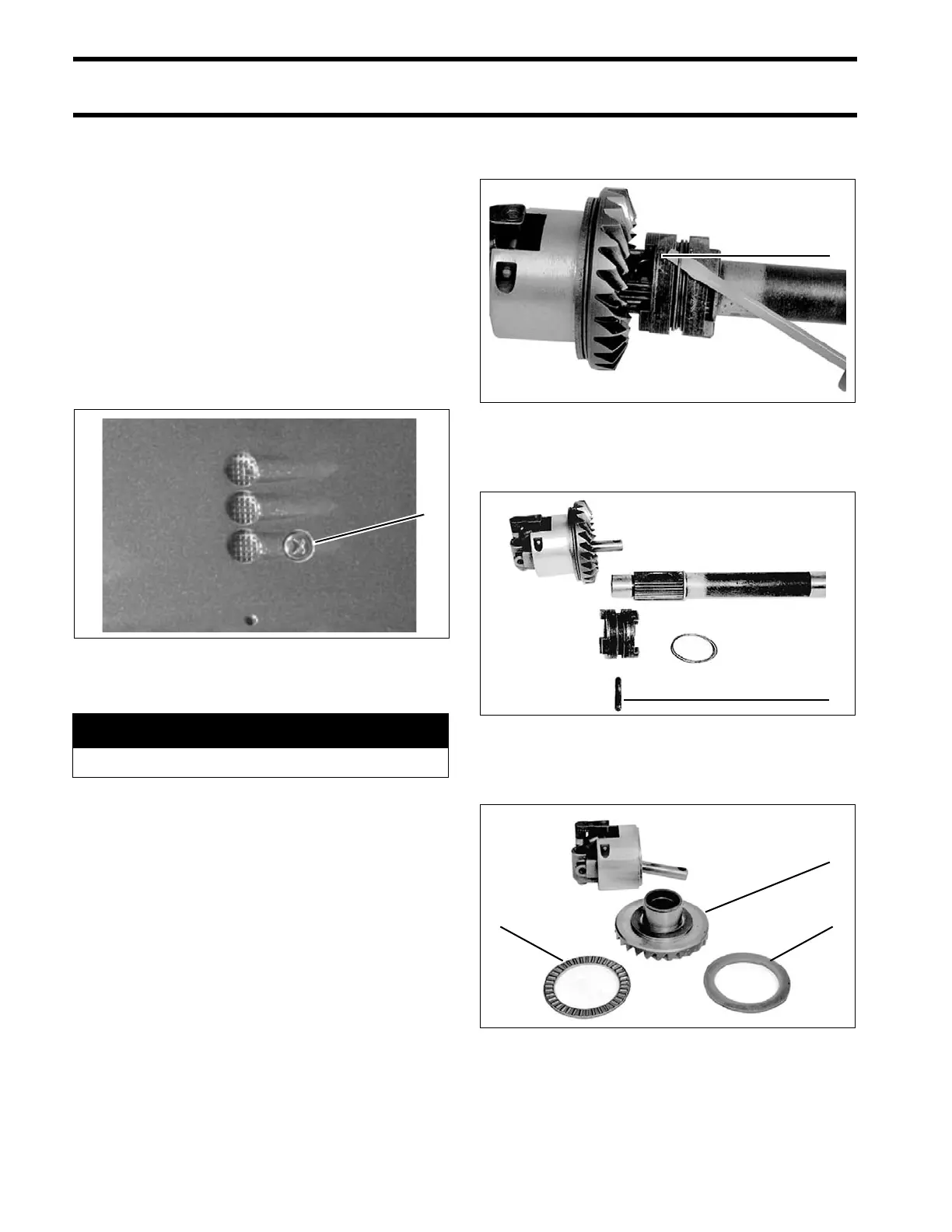

1. Clutch dog spring COA3560

1. Pin COA3561

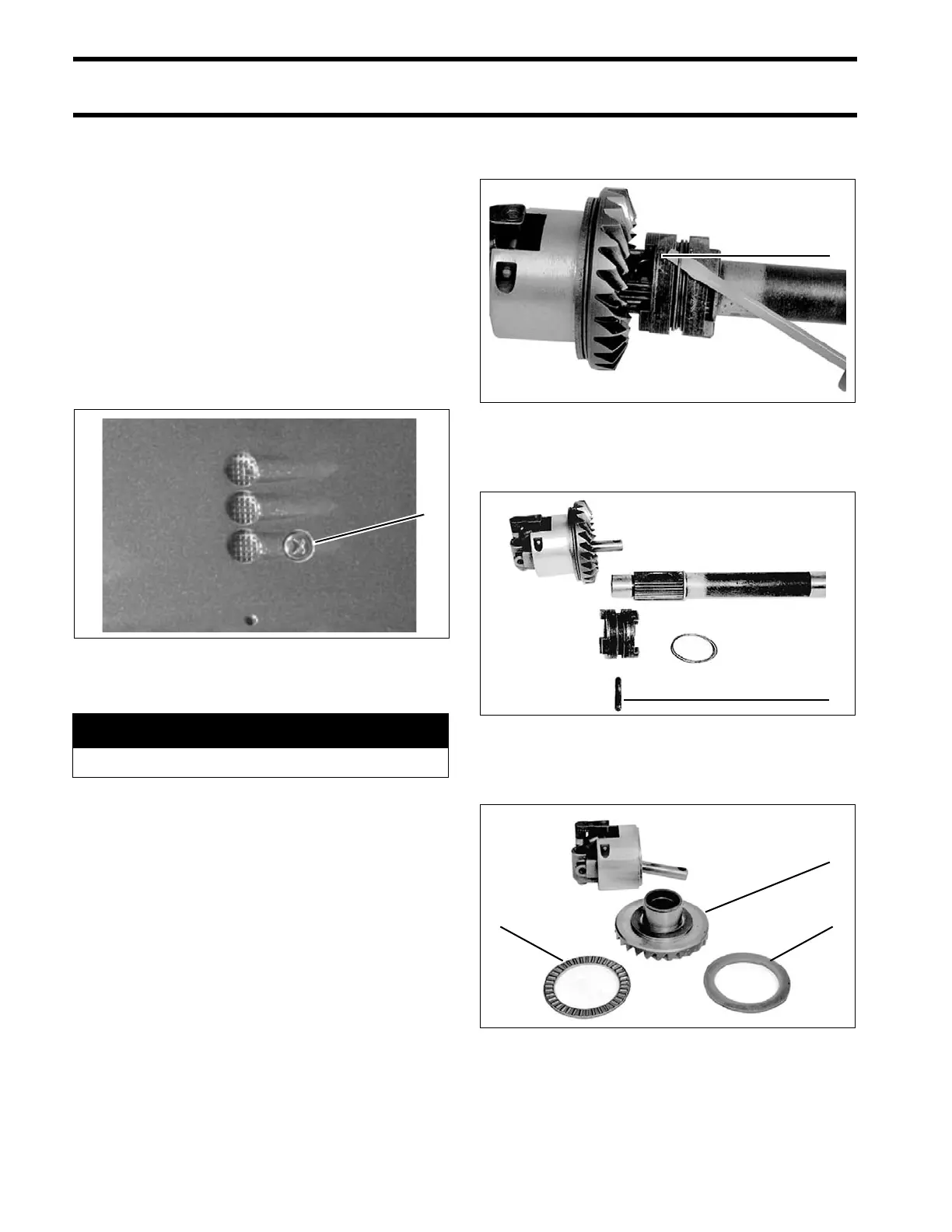

1. Gear

2. Thrust bearing

3. Thrust washer

COA3562

Loading...

Loading...