FARO Edge

September 2012

81

Chapter 6: Maintenance and Troubleshooting

and can be measured. The deformations must not exceed the deformation

reported at calibration.

In general, the excessive translation deformations are added directly to the

certified accuracy, while the excessive angular deformations of the base affect

accuracy as a more complicated trigonometric function of the length of the reach.

Temperature Considerations

FARO was awarded the U.S. patent #5,402,582, and worldwide patents are

pending, on the concept and the methods for temperature compensation of

portable CMM devices. This brief overview is meant only as the most general of

descriptions.

To maintain certified accuracy in a multitude of environments, the monitoring of

temperature and the rate of temperature change is required. Only the Edge

employs a software/hardware solution where a semiconductor temperature sensor

is built into each joint.

The temperature is continuously monitored and the difference over time is then

applied to the mathematical formulas or kinematics, which define the position of

the Edge in three-dimensional space. Link length corrections are made constantly

by the inboard processor, which adjusts the kinematics and constantly adapts the

output to changing environmental temperature.

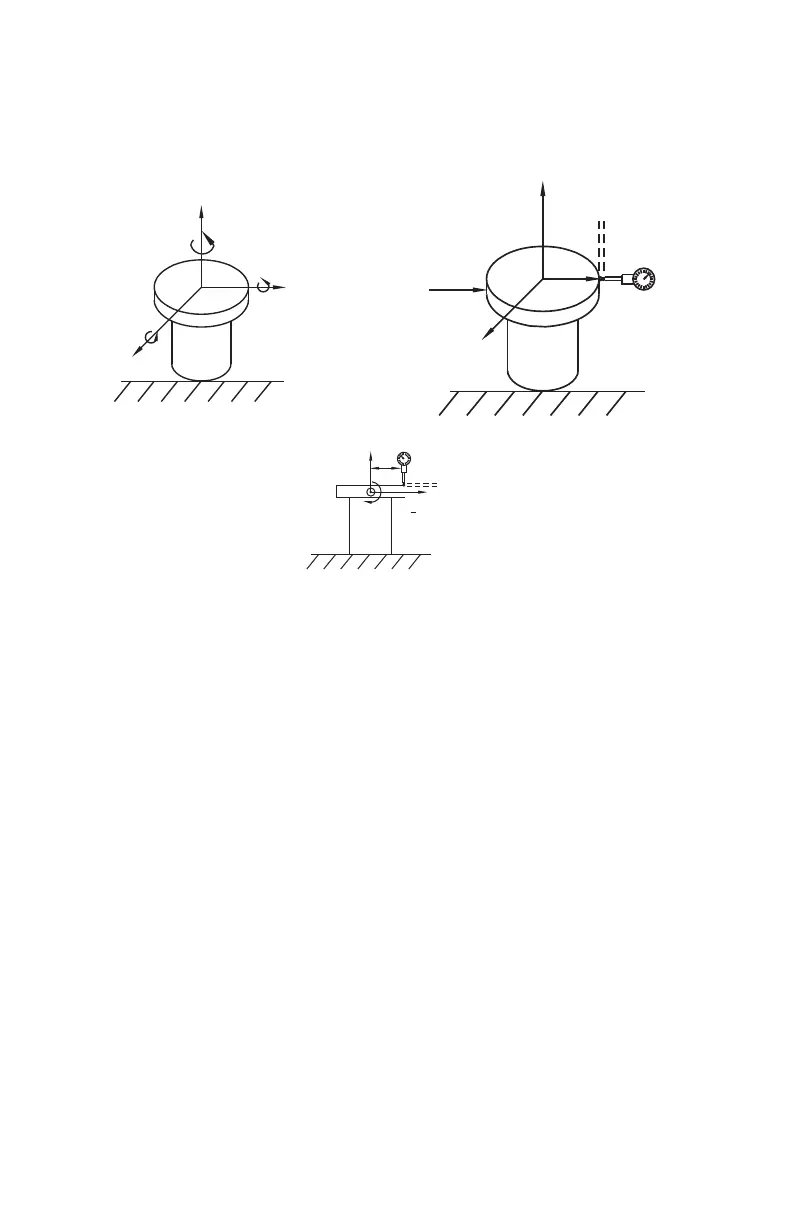

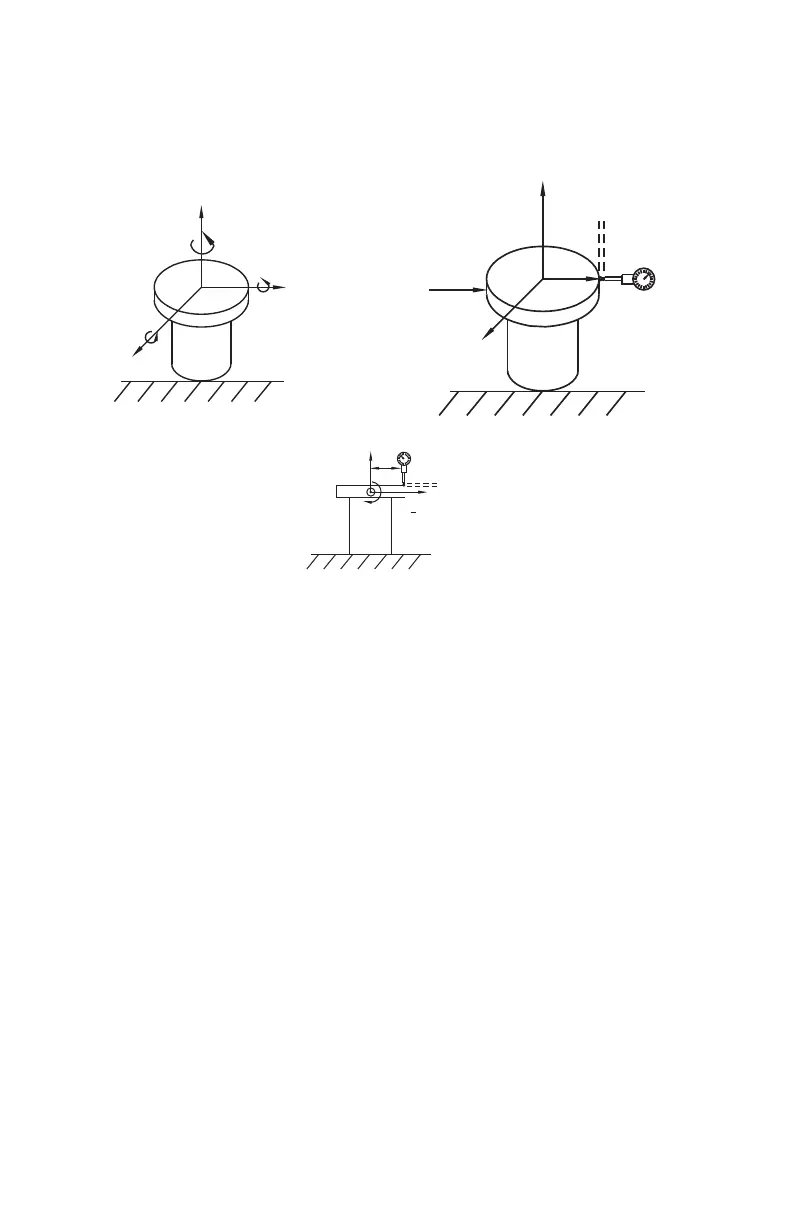

Forces Encountered due to

Counterbalancing

Displacement due to Force

Rotation due to Torque

FY

Y

M

Y

Mx

Moments (about X)

XF

X Forces (along X)

M

Z

Z

F

Z

Force

Displacement

due to Force

D

L

D

D

Rotation due to Torque

L

T

08M52E00_FaroArm_Edge.book Page 81 Thursday, October 4, 2012 9:31 AM

Loading...

Loading...