56

Receiver power supply

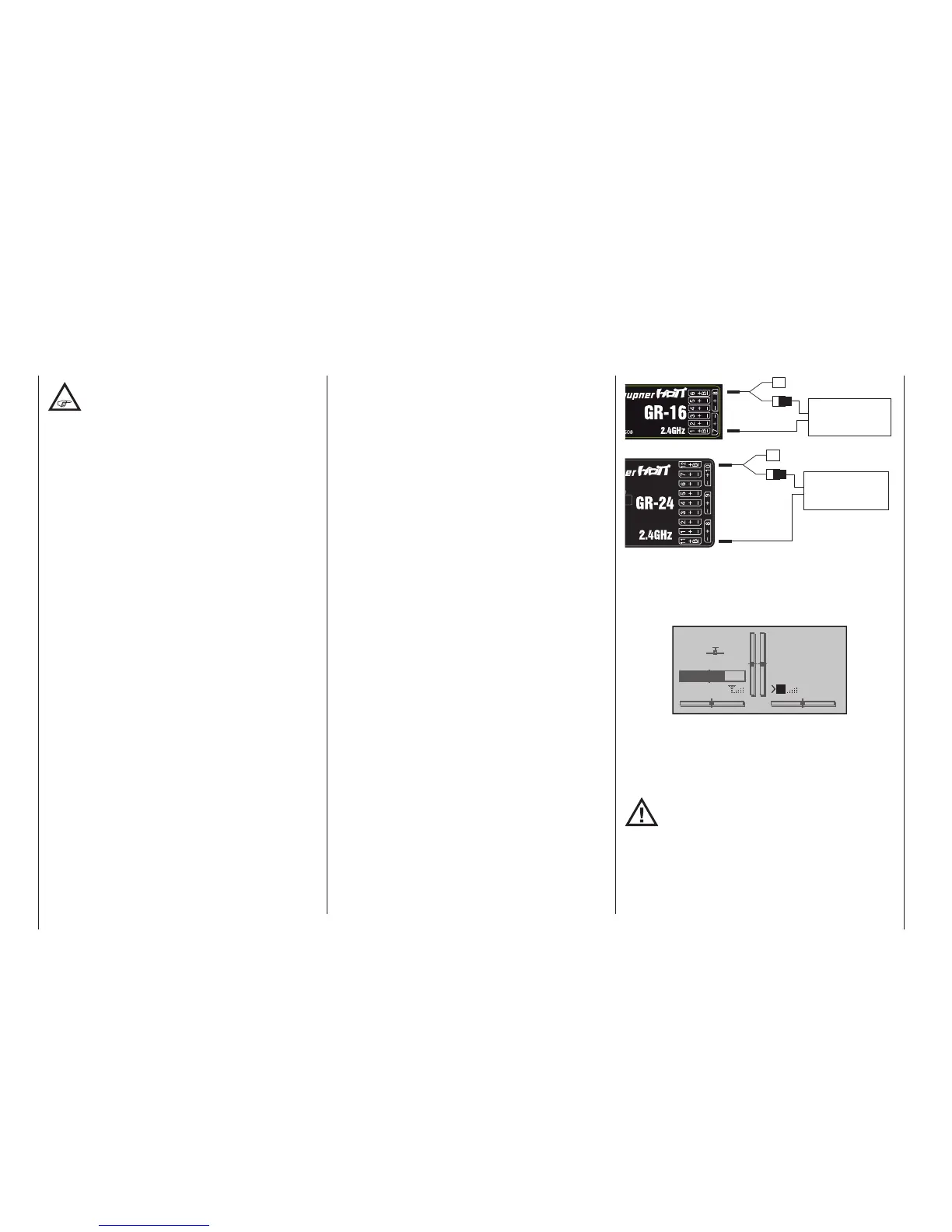

Auxiliary function

Y-lead,

Order No. 3936.11

PRX stabilised

receiver power supply,

Order No. 4136

Auxiliary function

Y-lead,

Order No. 3936.11

PRX stabilised

receiver power supply,

Order No. 4136

For reasons of safety, do not use battery boxes or dry

cell batteries.

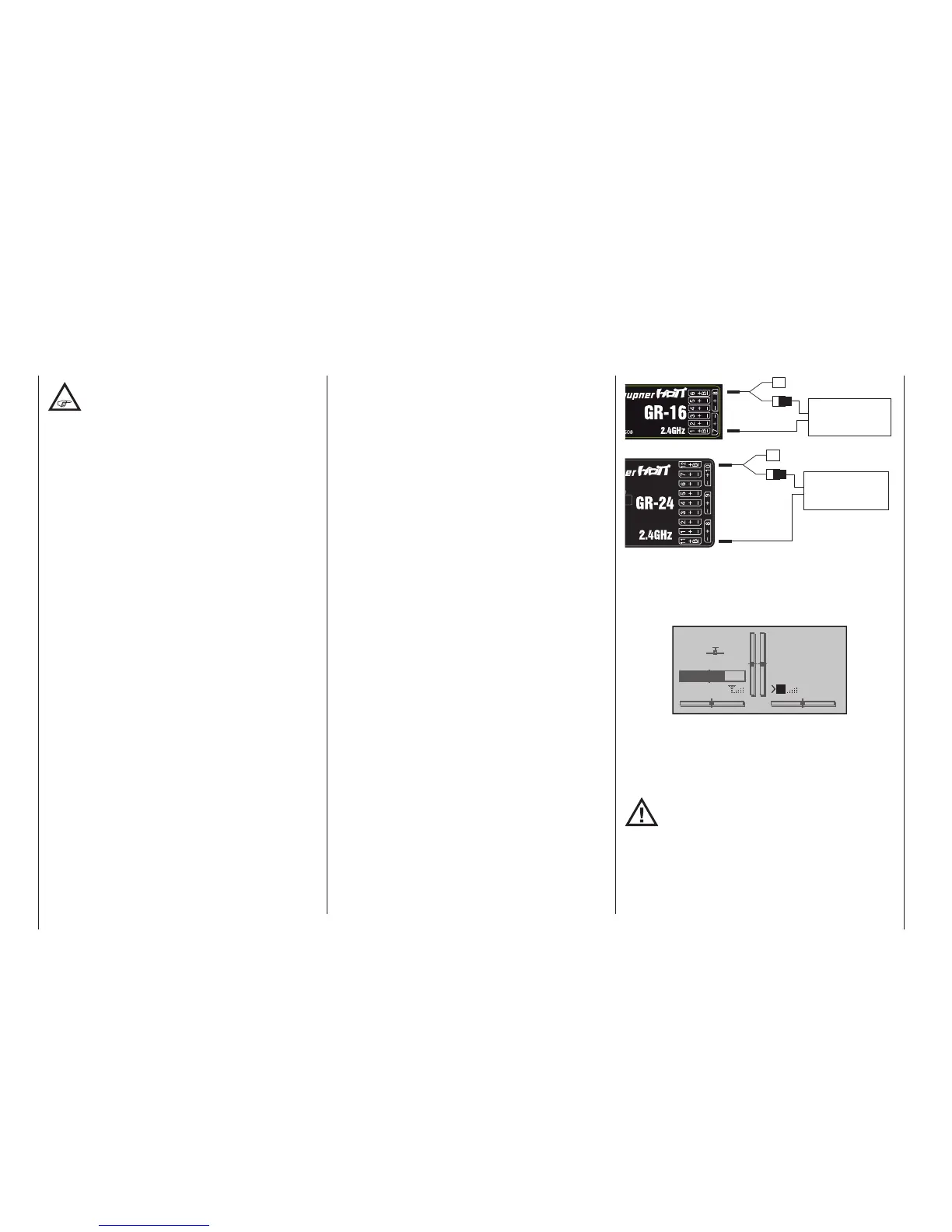

The voltage of the on-board power supply will be

displayed at the bottom right of the transmitter’s screen

while the model is in operation:

GRAUBELE

#01

2:22h

Stp

Flt

«normal »

K78

0:00

0:00

5.5V

3.9V

M

HoTT

If the voltage falls below the warning threshold – 3.80 V

as standard – set in the “RX SERVO TEST” display of

the “SETUP, DISPLAYS” sub-menu of the »Telemetry«

menu, page 250, then the system generates a visual

and audible low voltage warning.

Despite this feature, be sure to check the

condition of the battery at regular inter-

vals. Do not wait for the warning to be

issued before recharging the battery.

For example, from this point of view a battery with

1400 mAh would be the absolute minimum to power a

receiver system with a total of 4 analog servos. But be

sure to also consider the receiver itself into the calcu-

lation because its bidirectional functionality will draw

about 70 mA of current too.

Regardless, it is generally recommended that you con-

nect the receiver via two cables to the power supply:

cable “1” is to be as usual, plugged into the “12 + B”

port of the receiver and cable “2” at the opposite, with

“11 + B - “label, the end of the edge connector of the

receiver.

For example, by using a switch or voltage regulator

with two leading to the receiver power supply cable. If

necessary, use to connect them to the receiver a V or Y

cable No. 3936.11, see figure, if you need one or both

terminals of the receiver and to connect a servo, speed

controller etc.. They reduce by the double connection

to the switch or voltage regulator not only the risk of a

cable break, but also ensure more power to the con-

nected servos.

If a separate battery is connected to each receiver bat-

tery connection, be absolutely sure the batteries have

the same voltage and power rating. Never connect dif-

ferent battery types or batteries charged to significantly

different levels to the receiver. This can lead to effects

similar to short circuit conditions. In such cases, insert

voltage stabilizers, such as the PRX-5A receiver power

supply, between the batteries and the receiver.

Among other aspects, the safe operation of a

model depends on a reliable power supply. In

the event that, despite smooth operating rods,

fully charged battery, battery leads with adequate

cross-section, minimum contact resistances at con-

nectors, etc., the transmitter indicates repeated receiv-

er voltage collapses or is receiver voltage is generally

too low; please give attention to the following notices:

Give primary attention to fully charged batteries when

model operation is to be started. Be sure that the

contact surfaces of connectors and switches really

are low resistance. If necessary, measure the voltage

drop across installed switch cables when they are

under load because even new heavy-duty switches

can cause a voltage drop of up to 0.2 V. This value can

increase in contacts by factors as a consequence of

aging and oxidation. The constant vibrations and jarring

also takes its toll on contacts to produce a creeping

increase of contact resistance.

Servos present another possible problem source. Even

rather small servos like a Graupner/JR DS-281 can

draw up to 0.75 A of current when it is blocks under

load. Just four of these servos in a “foam” model can

therefore load down the on-board power supply by as

much as 3 A …

A further factor is that 2.4 GHz receivers generally pass

control signals to servos at a higher rate than with

comparable receivers used in earlier frequency ranges.

This equates to shorter “off” periods, which also has an

effect on the power consumption of the receiving sys-

tem. The current drain of many of today’s digital servos

is also higher, reflected by their greatly improved ability

to hold the prescribed position between control signals.

Therefore you should choose a power supply which will

not break down under greater loads but rather always

deliver sufficient voltage. To “calculate” necessary

battery capacity you should always figure on at least

350 mAh for every analog servo and at least 500 mAh

for every digital servo.

Receiver power supply

Loading...

Loading...