272

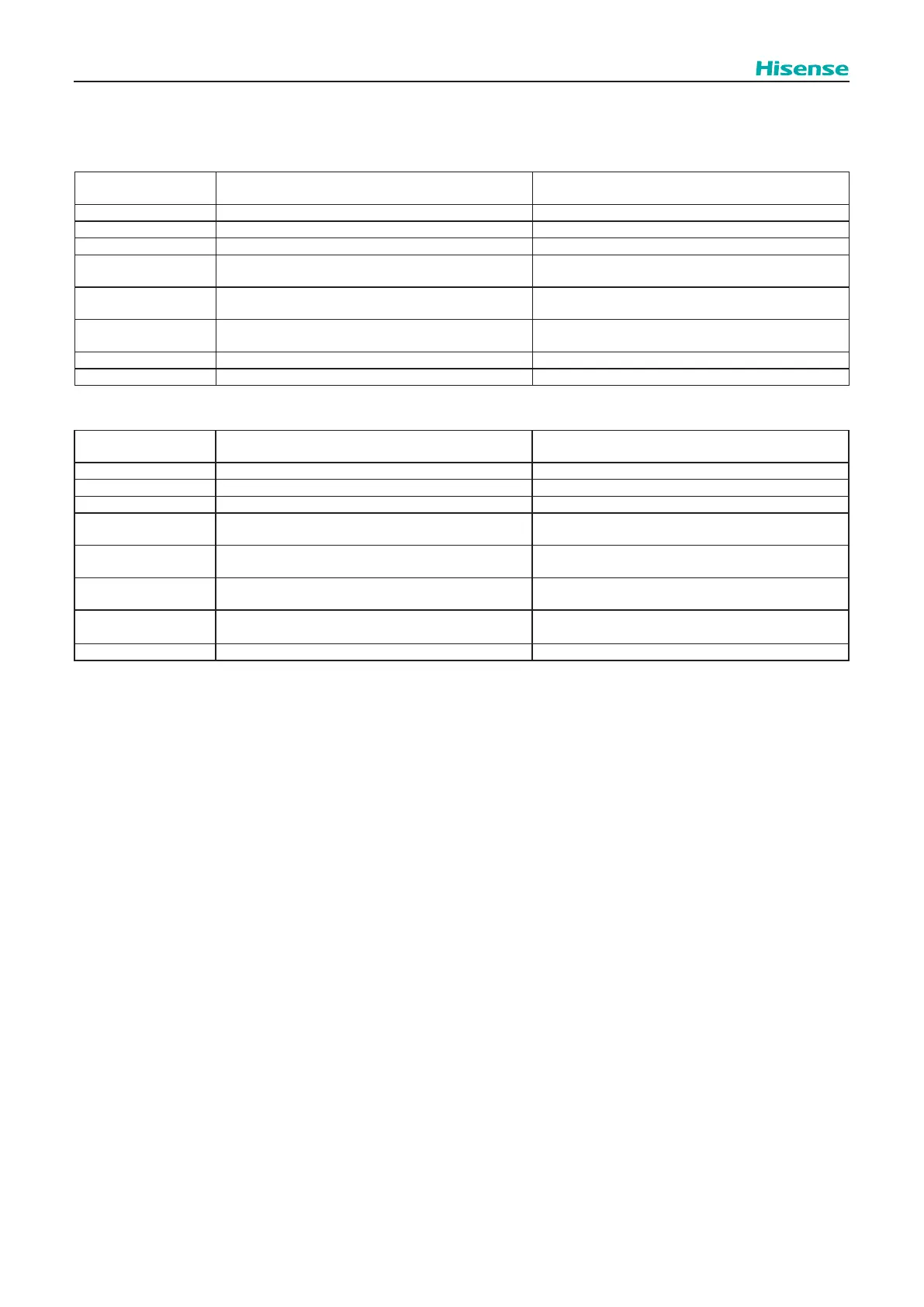

Control function

10.8.4 EC WP1 Water ow feedback

Water ow can be feedbacked by PWM output signal of Inside EC WP1 to monitor and estimate capacity.

PWM output signal (%)

[o-P] in 7-segments

Pump Status Potential causes

0 Pump PWM interface damaged iPWM interface in short circuit

2 Standby, pump is ready to run

5-75 Pump is running normally, ow information is supplied

80

Abnormal running mode: Pump is running but not at

optimal performance

Undervoltage 160/170-194 V Self-thermal protection

mode

85 Abnormal function mode Pump has stopped

Undervoltage <160/170 V Overvoltage >250 V

Unexpected external ow

90

Abnormal function mode Pump has stopped but still

functional Check the installation setup and the pump

Failure on another component than pump Debris in the

installation Bad temperature setup

95 The pump has stopped due to permanent failure Pump blocked Electric module out of order

100 Problem of PWM connection PWM interface in open circuit

10.8.5 Anti Freezing

If water temperature is 5ºC or lower in winter, and unit remains OFF, operate the water pump to protect the unit and pipes

installation from freezing. This control is released when the water outlet temperature becomes 7ºC or higher.

Set DSW4-6 ON to activate Anti Freezing. Anti Freezing is activated factory setting. Set DSW4-6: OFF to cancel Anti

Freezing through the Dip switch on PCB1.

NOTE:

1. Do not cancel Anti Freezing if ambient temperature around water circulation may be low to cause freezing damage.

There are 3 ways to do Anti Freezing.

①

Run WP1/WP2/WP3 and Room actuator to circulate warm water to do Anti Freezing when ambient temperature and

water temperature is low to cause frozen damage possibly.

②

Run water pump and Auxiliary electric heater to do Anti Freezing when ambient temperature and water temperature is

low continually after pump operation.

③

Run water pump and heat pump to do Anti Freezing when ambient temperature and water temperature is low continually

after Auxiliary electric heater operation.

NOTE:

1. Water temperature may drop to 3ºC before the unit begins to heat up water intentionally by Auxiliary electric heater or

heat pump.

There 2 ways to do water circulation when Auxiliary electric heater or heat pump is operated to do Anti Freezing.

● Circulate whole Water Cycle to keep all system warm when DSW3-4 is ON.

Run WP1/WP2/WP3 , Room actuator and mixing valve to circulate whole Water Cycle.

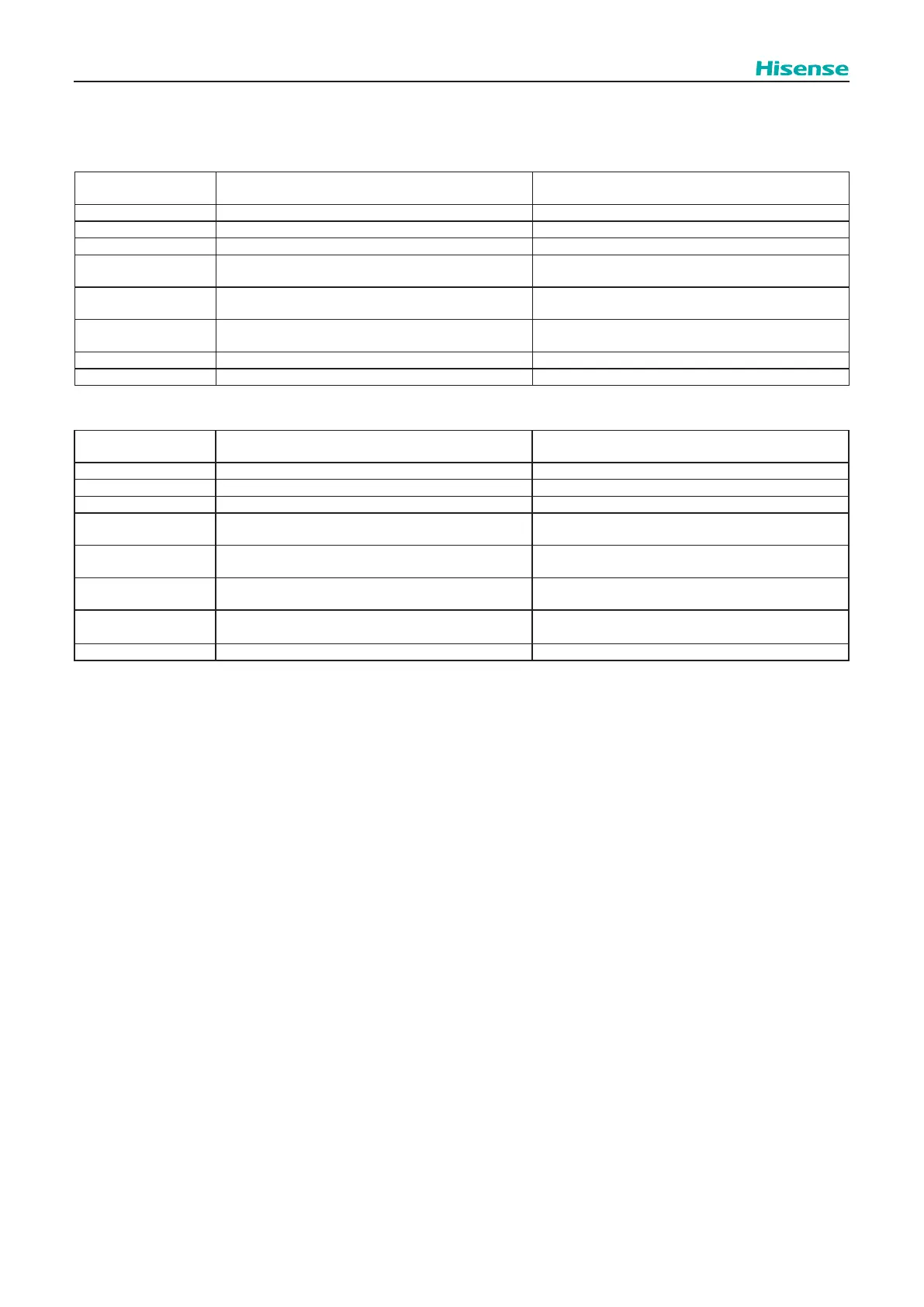

PWM output signal for Wilo and SHIMGE:

PWM output signal for GRUNDFOS:

PWM output signal (%)

[o-P] in 7-segments

Pump Status Potential causes

0 Pump PWM interface damaged iPWM interface in short circuit

95 Standby, pump is ready to run

0-70 Pump is running normally, ow information is supplied

75

Abnormal running mode: Pump is running but not at

optimal performance

Undervoltage 160/170-194 V

Self-thermal protection mode

80 Abnormal function mode Pump has stopped

Undervoltage <160/170 V Overvoltage >250 V

Unexpected external ow

85 Abnormal function mode Pump has stopped

Phase failure protection or overload short-circuit

protection.

90 Abnormal function mode Pump has stopped

Failure on another component than pump Debris in the

installation Bad temperature setup

100 Problem of iPWM connection PWM interface in open circuit

Loading...

Loading...