456

Hi-Therma Monobloc System (AHZ-044/080HCDS1)

2.4.6.6

Removing the Compressor

pipe connections. Otherwise, oil existing pipe inside may ignite.

Do not expose the refrigerant cycle to the atmosphere for a long period to avoid moisture or dust into the cycle. Be sure to replace

the compressor immediately after removing. Seal to the suction and discharge pipes when the refrigerant cycle is left unattached for a

prolonged time.

Remove the cap of new compressor right before the replacement. Before assembling the compressor, seal the suction and discharge

pipes with a tape to protect the compressor from foreign particles. Remove the tape at pipe connection.

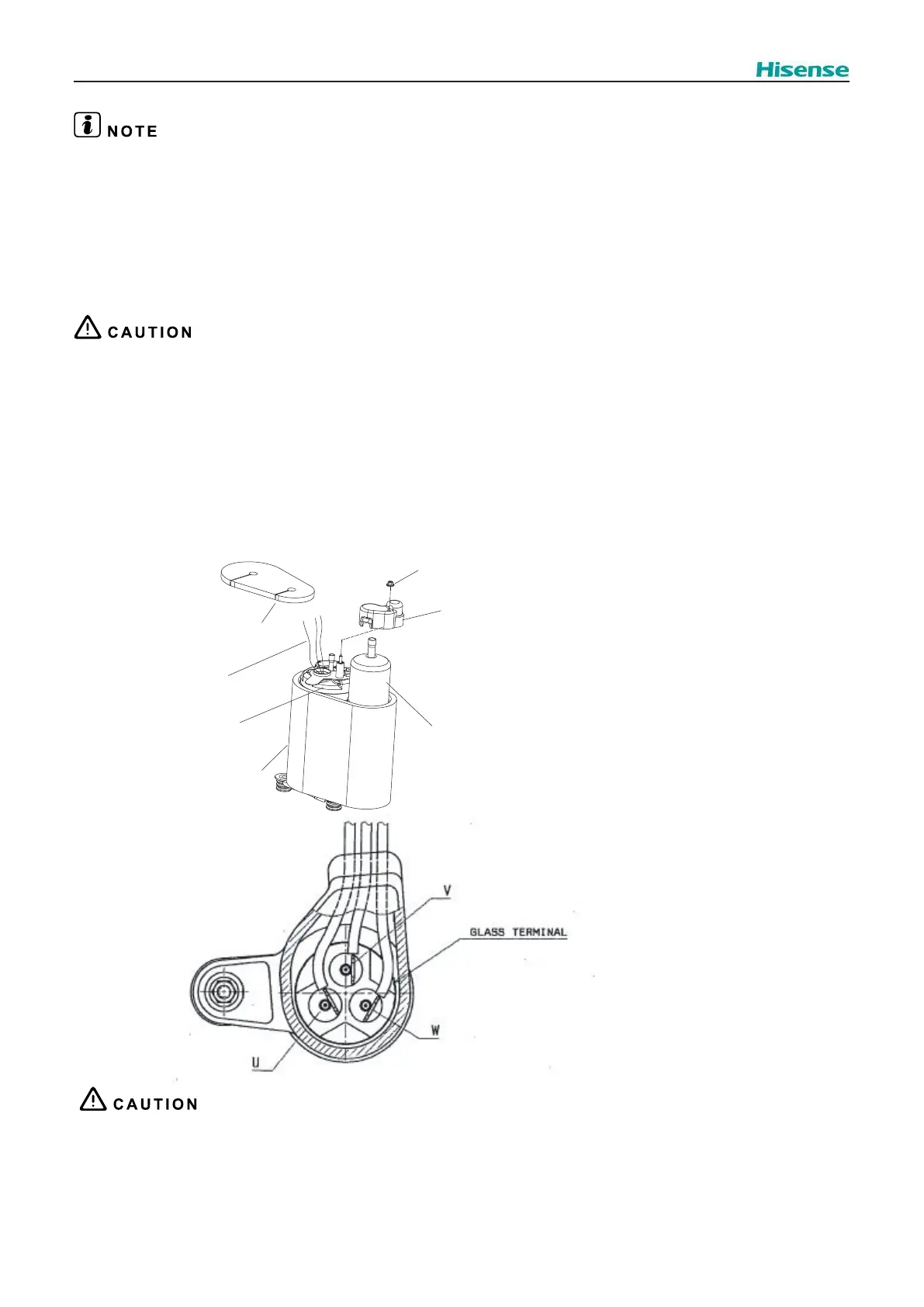

To connect wiring at reassembling ensure that the compressor terminal numbers and wiring mark band codes are matched. Incorrect

wiring numbers may result in reverse rotation and damage the compressor.

Flammable objects. Fire risk. All compressor pipes must be brazed to be connected to the refrigerant circuit.

Remove the upper cover, as explained in “2.3.1.1 Removing the Upper cover”

Remove the service cover, as explained in “2.3.1.2 Removing the Service cover”

Remove the electrical box cover, as explained in “2.3.1.3 Removing the Electrical box cover”

Remove the front cover, as explained in “2.3.1.4 Removing the Front cover”

Remove the rear cover, as explained in “2.3.1.5 Removing the Rear cover”

1. Collect the refrigerant from the check joint at the piping.

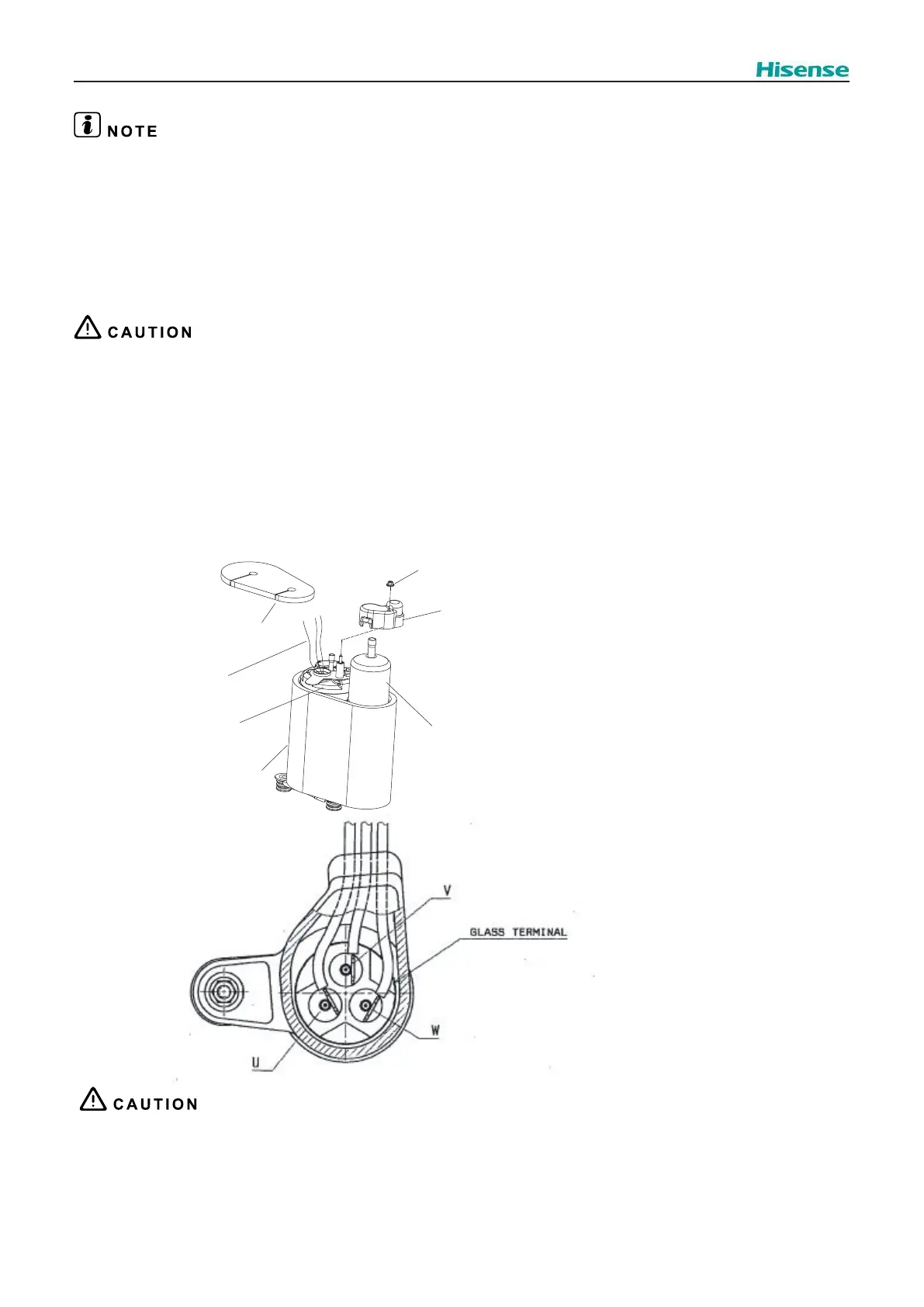

2. Open the soundproof cover wrapped around the compressor and remove the terminal box cover of the compressor

body. Disconnect the compressor wires in the terminal box.

top soundproof cover

Compressor

Side soundproof cover

nut

Terminal box cover

Accumulator

Compressor-top

thermistor and wiring

Check the wiring color and layout when disconnecting. Connecting wires in wrong order at reassembling may result in compressor damage.

3. Remove the suction and discharge pipes from the compressor.

part in order to avoid burning.

Loading...

Loading...