31

Capacity and selection data

3.3.2 Correction factor owing to use of glycol (only for Hi-Therma Monobloc)

Application at low ambient temperature

When the ambient temperature is low in winter, the water in the pipes and circulating pump may freeze and damage the pipes

and water pumps during shutdown periods.

To prevent this, it is useful to drain the water from the installation or not to cut o the power supply of the installation,

anti-freezing function will be triggered to prevent freezing.

In addition, in cases where it is dicult to drain the water, it is advisable to use a mixture with antifreeze glycol (ethylene or

propylene at a concentration between 10% and 35%).

When glycol is added to the system, the performance of the unit will be aected. The correction factor of the unit capacity,

ow rate and pressure drop of the system is listed in the tables below.

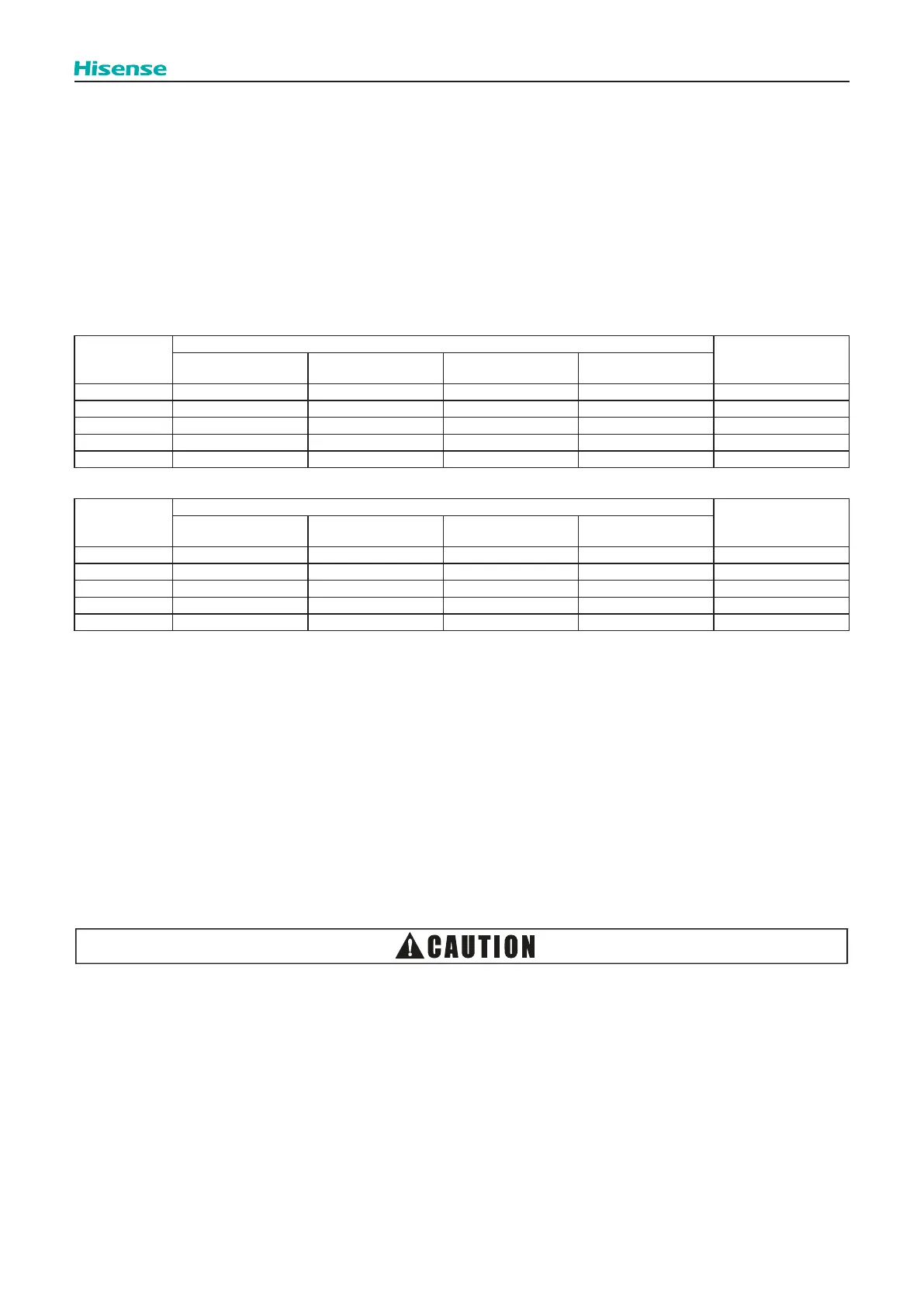

-Ethylene glycol

Concentration of

ethylene glycol

(%)

Modication coecient

Freezing point (°C)

Capacity Power input Water ow Water resistance

0 1.000 1.000 1.000 1.000 0

10 1.000 0.998 1.010 1.030 -4

20 1.000 0.995 1.010 1.090 -9

30 0.990 0.992 1.020 1.160 -16

35 0.990 0.991 1.030 1.210 -20

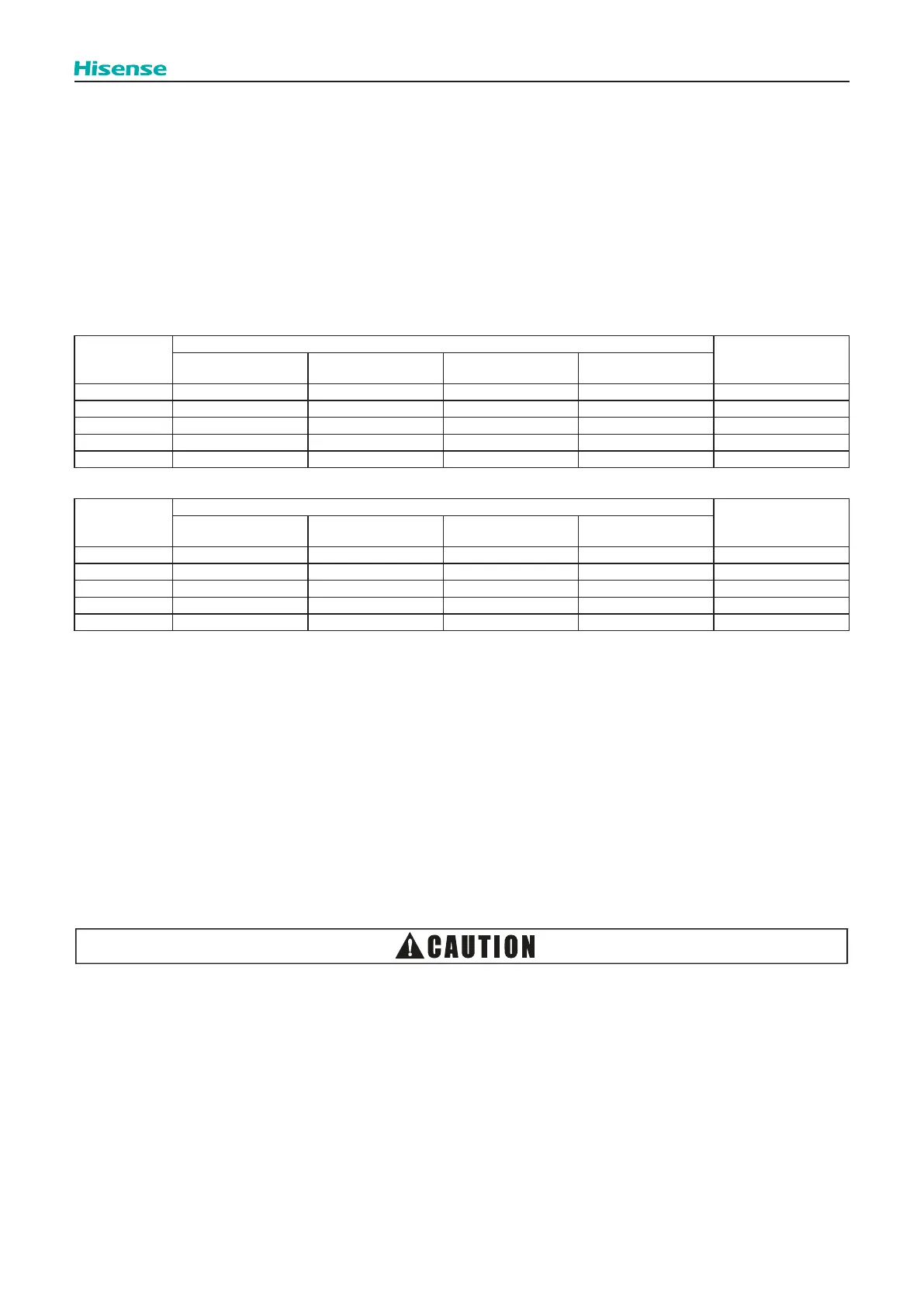

-Propylene glycol

Concentration of

propylene glycol

(%)

Modication coecient

Freezing point (°C)

Capacity Power input Water ow Water resistance

0 1.000 1.000 1.000 1.000 0

10 1.000 0.996 1.020 1.240 -3

20 1.000 0.992 1.020 1.310 -7

30 0.990 0.988 1.040 1.390 -13

35 0.990 0.986 1.050 1.450 -18

Uninhibited glycol will turn acidic under the inuence of oxygen. This process is accelerated by presence of copper and

at higher temperatures. The acidic uninhibited glycol attacks metal surfaces and forms galvanic corrosion cells that cause

severe damage to the system. It is of extreme importance:

- That the water treatment is correctly executed by a qualied water specialist.

- That a glycol with corrosion inhibitors is selected to counteract acids formed by the oxidation of glycols.

- That in case of an installation with a domestic hot water tank, only the use of propylene glycol is allowed. In other

installations the use of ethylene glycol is ne.

- That no automotive glycol is used because their corrosion inhibitors have a limited lifetime and contain silicates that can

foul or plug the system;

- That galvanized piping is not used in glycol systems since it may lead to the precipitation of certain elements in the

glycol’s corrosion inhibitor;

- To ensure that the glycol is compatible with the materials used in the system.

The use of glycol aects to the reading of some parameters like “water ow level” and “capacity” shown through the unit

controller menu. When glycol is used, these data are not correct and must be not used.

Loading...

Loading...