394

Hi-Therma Split system - Outdoor unit (AHW-044/060/080HCDS1)

2. Servicing

2.1 Hi-Therma Split system - Outdoor unit (AHW-044/060/080HCDS1)

Safety Introduction

? NOTE

! DANGER

! DANGER

DO NOT TOUCH THE ELECTRICAL COMPONENTS WHILE LEDS on O.U. MAIN PCB or LED1 on O.U. DISPLAY PCB

ARE ON, TO AVOID ELECTRICAL SHOCK.

WAIT UNTIL ALL LEDS TURN OFF.

security lockers or convenient warning indicators in order to prevent them from turning on accidentally.

In case of blocked or stucked parts use appropiated tools and eventually lubricants to release them.

In case of sharped edged parts as covers use security gloves to avoid getting injured.

When performing brazing work besides security gloves it is must to wear convenient eye protection.

Check and be sure that all LEDS on the O.U. main PCB or display PCB are OFF for all electrical maintenance.

pipe connections if not oil existing pipe inside may ignite.

Do not expose the refrigerant cycle to the atmosphere for a long period in order to avoid mixing the water and foreign particles into the

refrigerant cycle. After removing compressor replace it quickly. If exposed for a long period seal the suction pipe and discharge pipe.

Remove the cap for the compressor just before replacing the compressor. Before mounting the compressor seal the suction pipe and

discharge pipe with a tape to protect the compressor from foreign particles. Remove the tape at pipe connection.

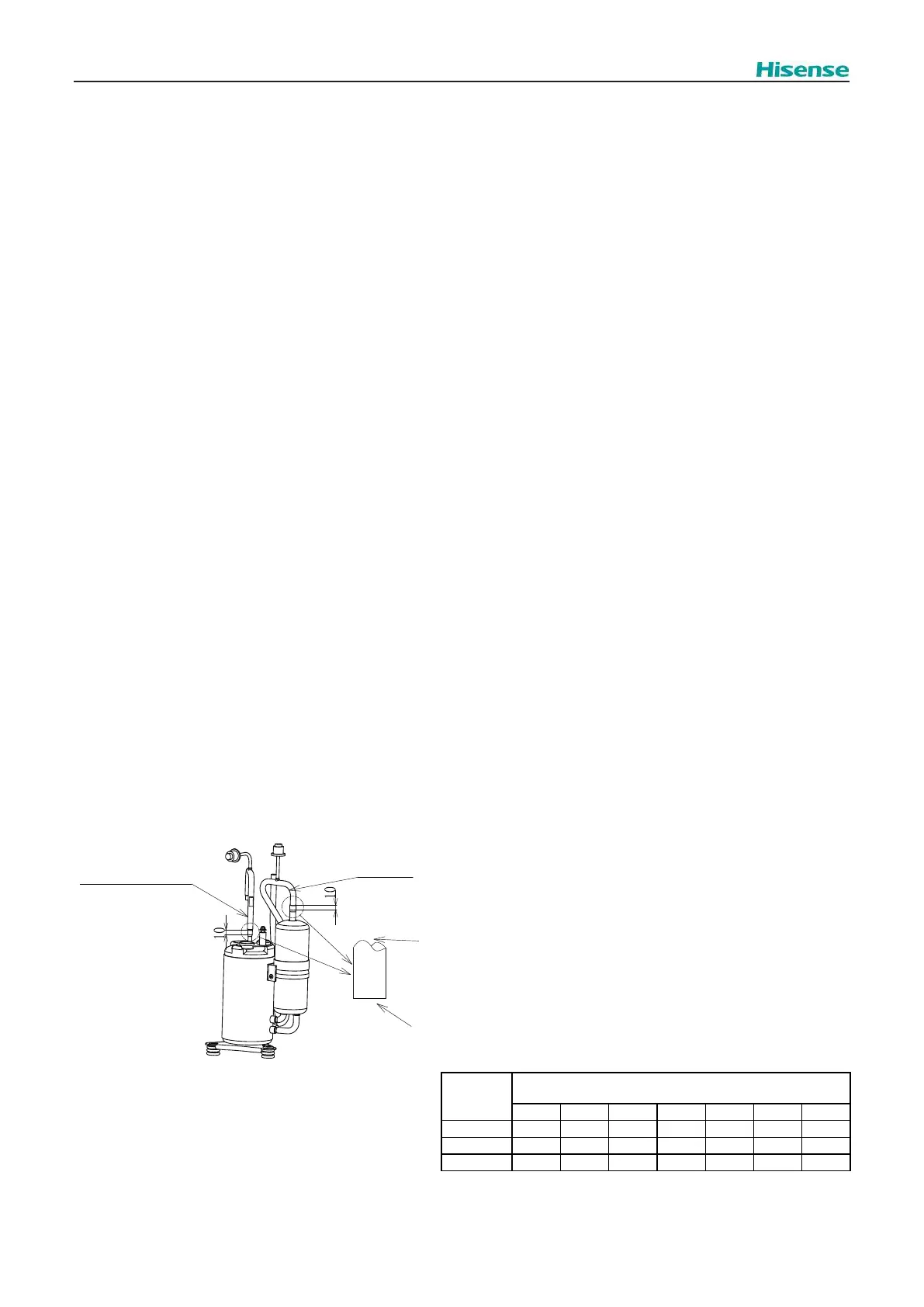

Caution for Replacement of Compressor

Remove the suction pipe and the discharge pipe from the compressor. Isolate the wires and electrical components to protect

When replacing the compressor, the brazed material used for connecting the compressor and refrigerant pipes can drop

into the pipes and get sucked into the compressor, causing a compressor failure. To avoid this, take the following points into

account when replacing the compressor:

a . File away brazing material remaining on the end of the refrigerant pipes.

b . Insert the pipes fully in to prevent brazing material from entering them.

c . Refer to the table for the recommended amount of brazing material. If using more brazing material than the

recommended amount, it may drop into the pipes.

! CAUTION

When brazing the pipes, prevent oxidized scale formation

by nitrogen substitution.

Thickness

of brazing

material

Piping diameter (refrigerant cycle side) (mm)

Ø6.35 Ø9.53 Ø6.35 Ø12.7 Ø15.88 Ø19.05 Ø22.2

Ø1.6mm 25 30 35 35 75 100 110

Ø2.0mm 15 15 10 20 45 55 70

Ø2.4mm 10 10 15 15 30 35 45

Dis

charg

e

pipe

Suct

ion

pip

e

Suction and discharge pipe removed from

compressor

File away the brazing material remaining on the end of the suction

and discharge pipes

Loading...

Loading...