122

Installation

8.2.10.5

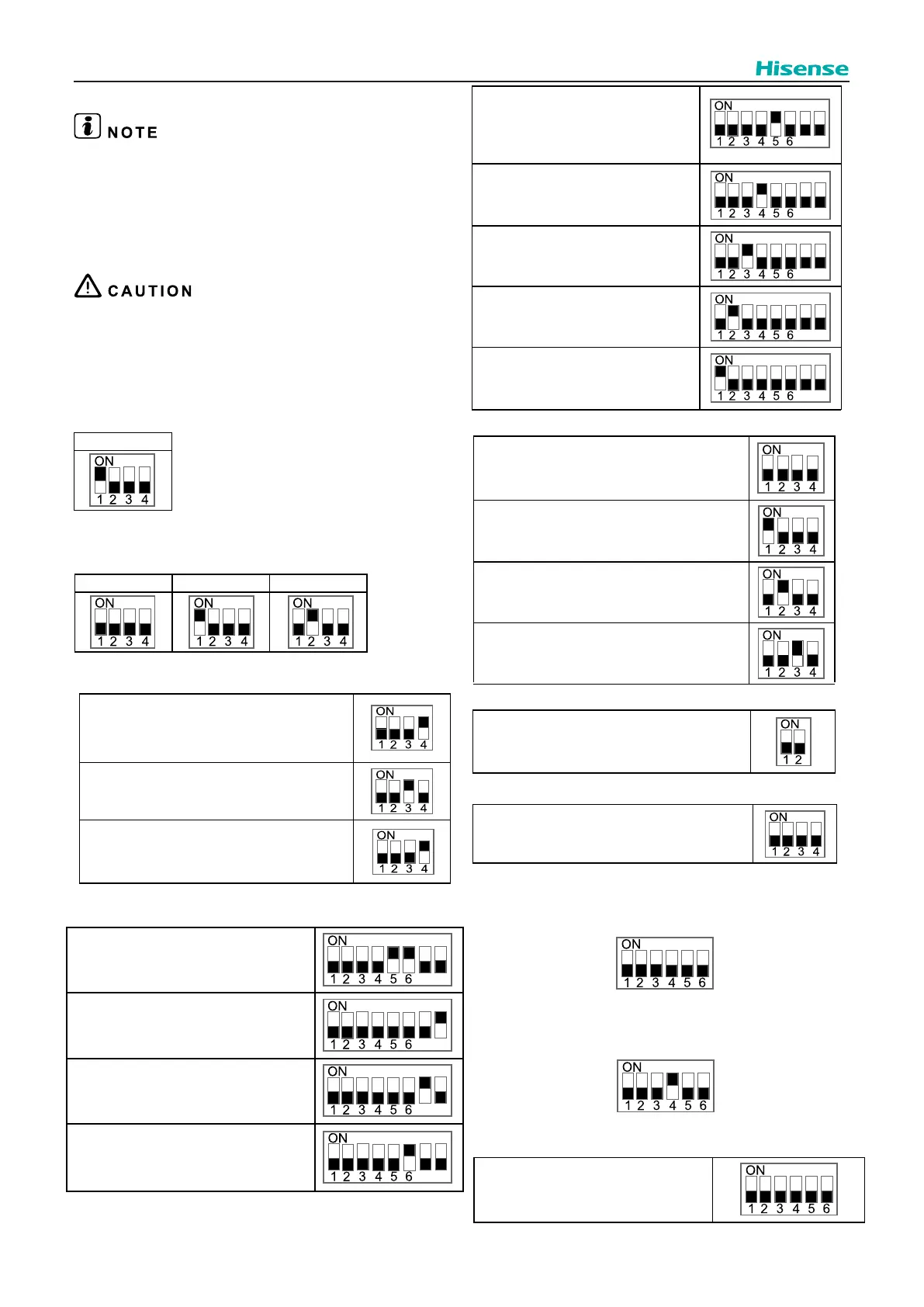

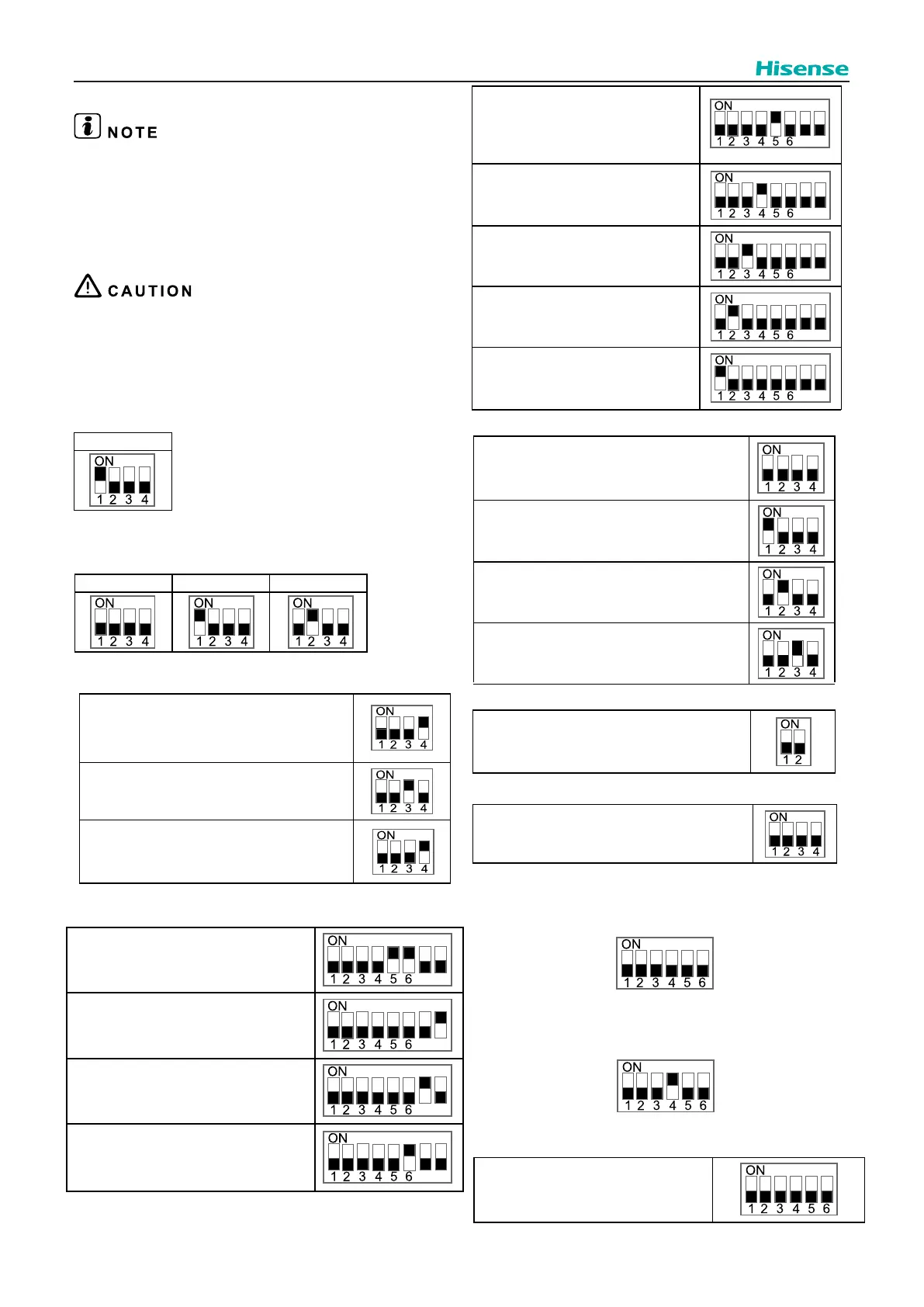

SETTING OF DIP SWITCHES ON PCB1

selection.

malfunction might occur if changed.

then set the position of dip switches. If the switches are set without

(1) DSW1: Unit model setting

No setting is required.

(2) DSW2: Unit capacity setting

No setting is required.

Combi

044(2.0 HP) 060(2.5 HP) 080(3.0 HP)

(3) DSW3: Additional setting

(4) DSW4: Additional setting

6HWWLQJEHIRUHVKLSPHQW

$QWLIUHH]LQJVHWWLQJV

21:KROHZDWHUF\FOHGRHVDQWLIUHH]LQJ

2))2QO\SULPDU\F\FOHGRHVDQWLIUHH]LQJ

21&DQFHODODUP:DWHUSUHVVXUHDEQRUPDOLW\

Setting before shipment

7 8

Water pump forced ON

7 8

Auxiliary electric heater

forced OFF

7 8

ON: Anti-freezing enabled

OFF: Anti-freezing disabled

7

8

Manual emergency setting

ON: Manual emergency enabled

OFF: Manual emergency disabled

7 8

DHW electric heater allowance setting

ON: DHW electric heater cancel forced OFF

OFF: DHW electric heater forced OFF

7

8

DHW 3-way valve forced ON

7 8

Start air purge

7 8

Water pump mode when

Thermo OFF

OFF: Operate constantly

ON: Operate periodically

7

8

(5) DSW5: Additional setting

(6) DSW6: Fuse reset

(7) DSW7: Not used

(8) DSW8: Refrigeration system No. setting

Setting is required.

Use binary encoding method. Before shipment are all OFF.

(9) DSW9: Indoor unit No. setting.

No setting is required.

Max No.63 are available to set when all the equipment are

connected to corresponding Central Control System.

Ex: Set refrigeration system No. as 8.

Setting before shipment

Setting before shipment

ON: WP3 operates in space cooling mode.

ON: Cancel 75/78 alarm (Water pump abnormalities)

ON: &DQFHO$ODUPRI7KHUPLVWRU7RZ.

Loading...

Loading...