MASSO

MASSO Documentation

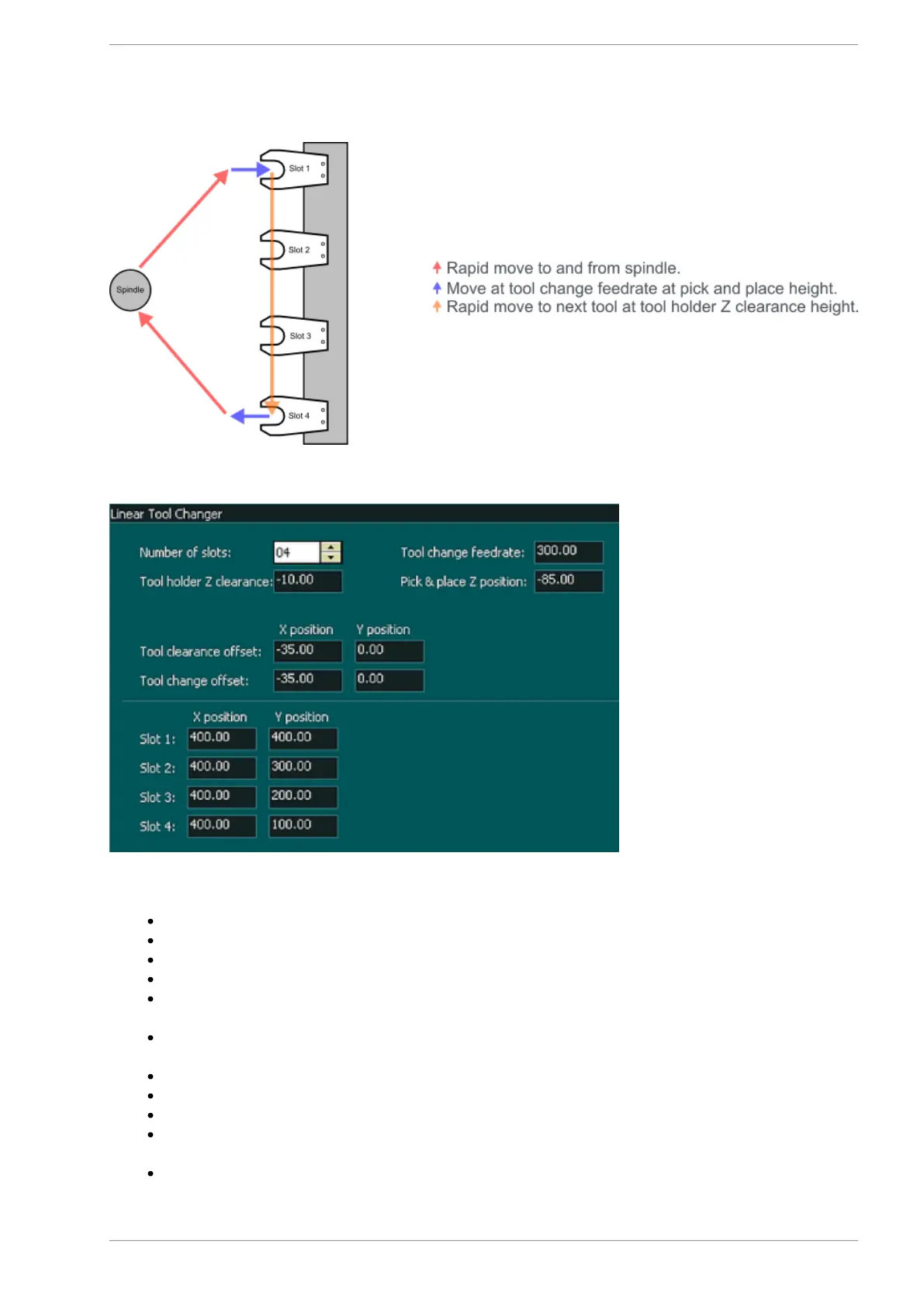

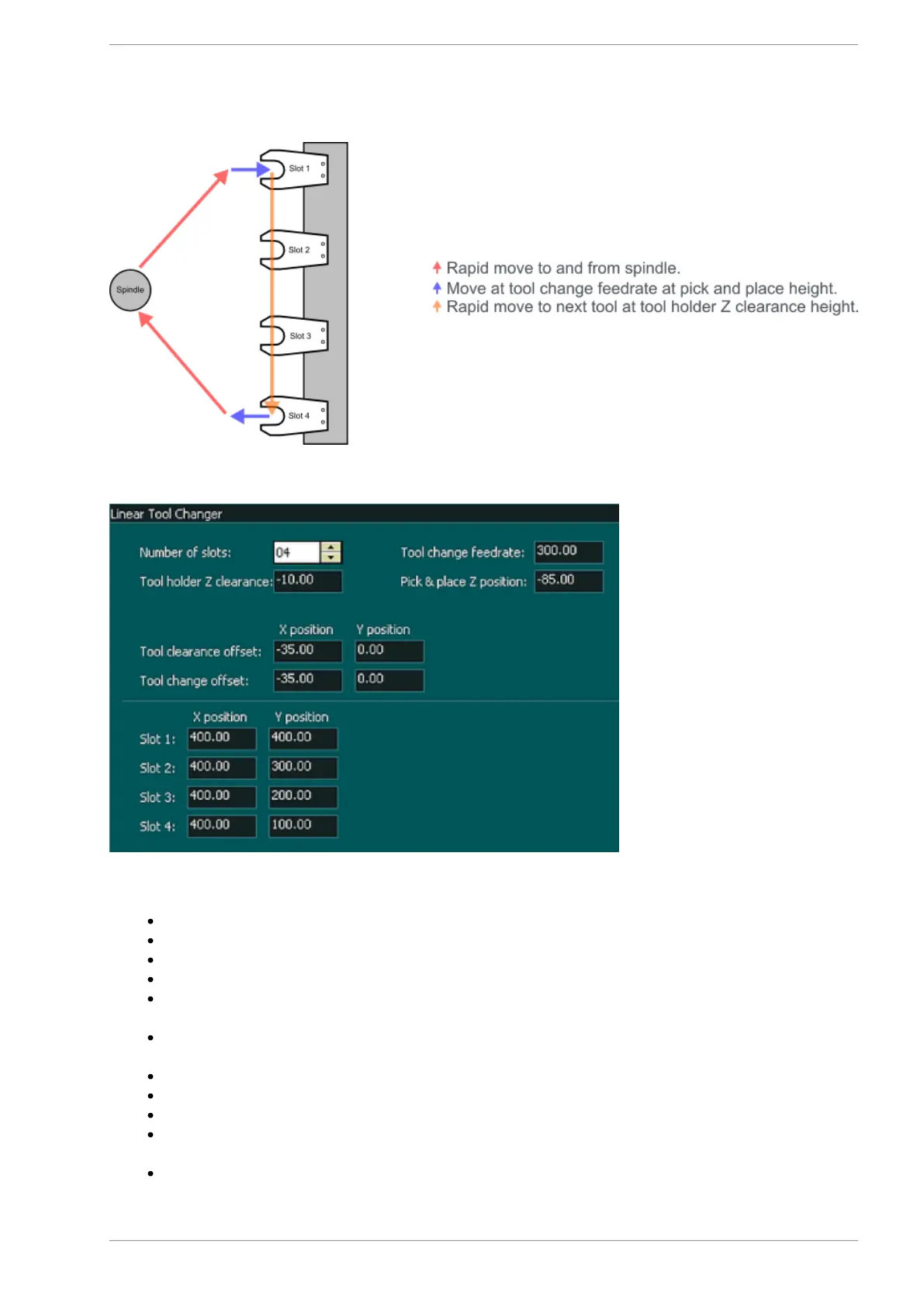

In the following example Tool 1 is in Slot 1 and Tool 2 is in Slot 4

Current tool loaded Tool 1

Gcode T2 M06

Spindle rapids to Machine coordinate X365 Y400 (Tool clearance / Tool change offset coordinate)

Because the Tool clearance offset and the Tool change offset are in the same position the next move

is the Tool change

Move at feed rate 300mm/m at a Machine coordinate Z height of Z-85 to X400 Y400 (Slot 1

Coordinate)

Chuck clamp released and Z rises to Machine coordinate Z-10

Rapid move to X400 Y200 (Slot 4 Coordinate)

Z descends to Z-85 and chuck clamp locks

Move at feed rate 300mm/m at a Machine coordinate Z height of Z-85 to X365 Y200 (Tool Change

offset coordinate)

Z-axis ascends maximum height and rapids to original spindle position

v5.18 - 08 Apr,2021

www.masso.com.au Page 419 of 477

Loading...

Loading...