Training Guide Course No. 196514

Level 2 Maintenance, X-1000 Series Dispensing Systems 4-93 P/N 196515 (Revision A)

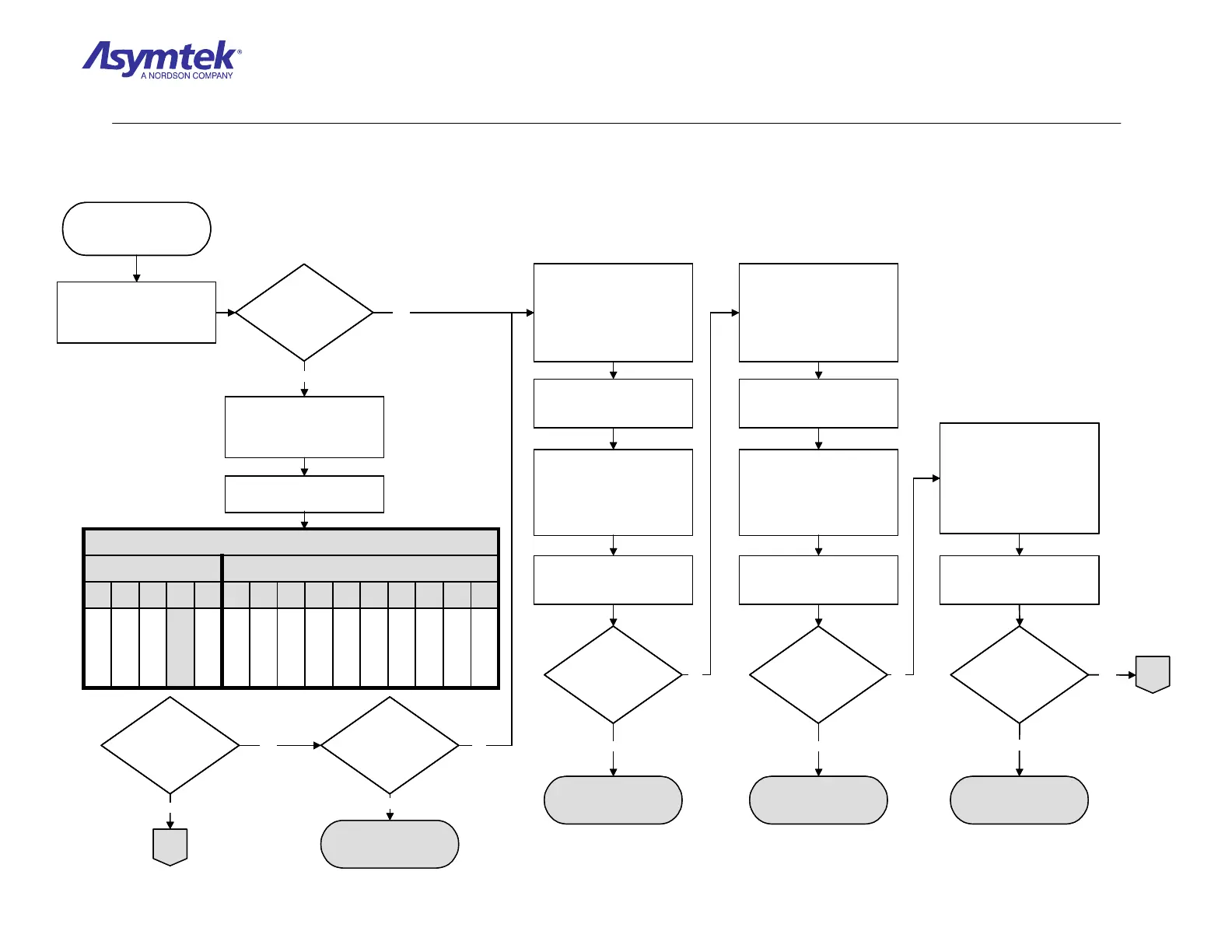

Are all

pneumatic system

devices inoperative

and yellow Beacon

light flashing?

Connect the Power Cable to

the facility outlet,

Main Air Solenoid (P/N 40-

2125) has failed.

Switch Main Circuit Breaker

to ON (I), press the green ON

(I) button on the Operator’s

Console and open FmNT.

From FmNT Main Window:

a. Select Tools.

b. Select I/O Test.

c. Select Conveyor.

Toggle the failed pneumatic

device. Refer to table below:

TABLE 1

Purge Cup

!A

Center Vacuum

1B

Left Vacuum

2A

Right Vacuum

2B

Left Stop Pin

3

Center Stop Pin

4

Center Lift Table

5

Right Stop Pin

6

Left Lift Table

7

Right Lift Table

8

X-1020

Purge Cup

Left Stop Pin

Center Stop Pin

Center Lift

1A2345

X-1010

Did the LED illuminate

on the Solenoid Valve?

Can tooling pressure

be adjusted to 40 psi?

Exit FmNT, shut down

Windows NT, press the black

OFF (0) button on the

Operator’s Console, switch

Main Circuit Breaker to OFF

(0), and disconnect Power

Cable from the facility outlet.

Remove Main Air Solenoid

Connector from J33 on XY

Servo Interface PWA.

Connect the Power Cable to

the facility outlet, switch Main

Circuit Breaker to ON (I)

position, press the green ON

(I) button on the Operator’s

Console, and enter FmNT.

Measure VDC on XY Servo

Interface PWA J33, Pin 1 and

Pin 2.

Is the reading 24

VDC?

Exit FmNT, shut down

Windows NT, press the black

OFF (0) button on the

Operator’s Console, switch

Main Circuit Breaker to OFF

(0), and disconnect Power

Cable from the facility outlet.

Remove Servo Interconnect

B Cable from J20 on XY

Servo Interface PWA.

Connect the Power Cable to

the facility outlet, switch Main

Circuit Breaker to ON (I)

position, press the green ON

(I) button on the Operator’s

Console, and enter FmNT.

Measure VDC on Servo

Interconnect B Cable P20,

Pin 22, and Pin 37.

Is the reading 5VDC?

Exit FmNT, shut down

Windows NT, press the black

OFF (0) button on the

Operator’s Console, switch

Main Circuit Breaker to OFF

(0) position, and disconnect

Power Cable from the facility

outlet.

Is there continuity?

Check continuity of Servo

Interconnect B Cable (Pinout

is 1 to 1).

XY Servo Interface PWA

(P/N 194036) has failed

Servo Interconnect B

Cable (P/N 06-4525-00)

has failed.

A

A

Solenoid Valve (P/N

197396 4-way or P/N

197397 Dual 3-way) has

failed

No

Yes

No

YesNo

Yes

No

Yes

No

Yes

No

Yes

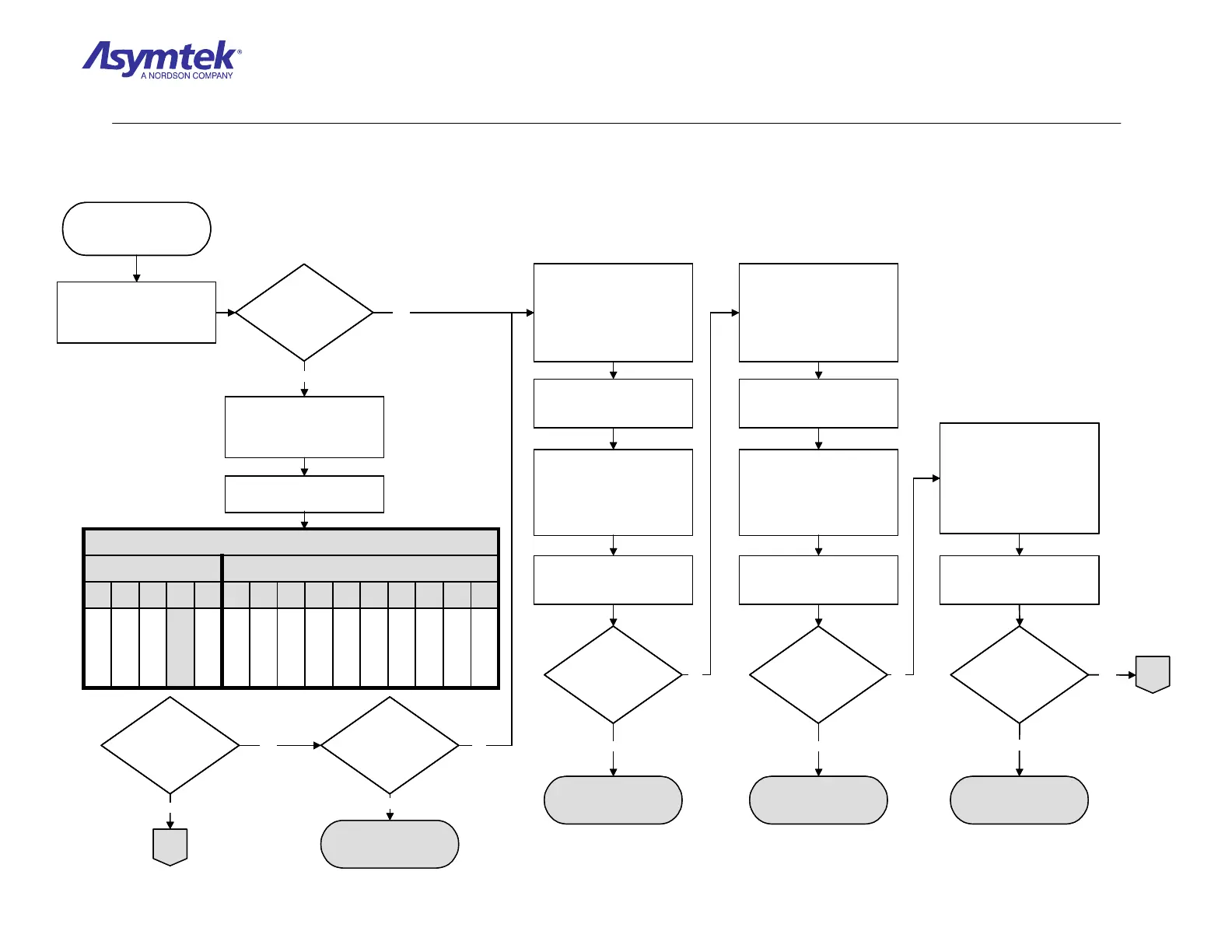

Are all

pneumatic system

devices inoperative

and yellow Beacon

light flashing?

Are all

pneumatic system

devices inoperative

and yellow Beacon

light flashing?

Connect the Power Cable to

the facility outlet,

Main Air Solenoid (P/N 40-

2125) has failed.

Switch Main Circuit Breaker

to ON (I), press the green ON

(I) button on the Operator’s

Console and open FmNT.

From FmNT Main Window:

a. Select Tools.

b. Select I/O Test.

c. Select Conveyor.

Toggle the failed pneumatic

device. Refer to table below:

TABLE 1

Purge Cup

!A

Center Vacuum

1B

Left Vacuum

2A

Right Vacuum

2B

Left Stop Pin

3

Center Stop Pin

4

Center Lift Table

5

Right Stop Pin

6

Left Lift Table

7

Right Lift Table

8

X-1020

Purge Cup

Left Stop Pin

Center Stop Pin

Center Lift

1A2345

X-1010

TABLE 1

Purge Cup

!A

Center Vacuum

1B

Left Vacuum

2A

Right Vacuum

2B

Left Stop Pin

3

Center Stop Pin

4

Center Lift Table

5

Right Stop Pin

6

Left Lift Table

7

Right Lift Table

8

X-1020

Purge Cup

Left Stop Pin

Center Stop Pin

Center Lift

1A2345

X-1010

Did the LED illuminate

on the Solenoid Valve?

Did the LED illuminate

on the Solenoid Valve?

Can tooling pressure

be adjusted to 40 psi?

Can tooling pressure

be adjusted to 40 psi?

Exit FmNT, shut down

Windows NT, press the black

OFF (0) button on the

Operator’s Console, switch

Main Circuit Breaker to OFF

(0), and disconnect Power

Cable from the facility outlet.

Remove Main Air Solenoid

Connector from J33 on XY

Servo Interface PWA.

Connect the Power Cable to

the facility outlet, switch Main

Circuit Breaker to ON (I)

position, press the green ON

(I) button on the Operator’s

Console, and enter FmNT.

Measure VDC on XY Servo

Interface PWA J33, Pin 1 and

Pin 2.

Is the reading 24

VDC?

Is the reading 24

VDC?

Exit FmNT, shut down

Windows NT, press the black

OFF (0) button on the

Operator’s Console, switch

Main Circuit Breaker to OFF

(0), and disconnect Power

Cable from the facility outlet.

Remove Servo Interconnect

B Cable from J20 on XY

Servo Interface PWA.

Connect the Power Cable to

the facility outlet, switch Main

Circuit Breaker to ON (I)

position, press the green ON

(I) button on the Operator’s

Console, and enter FmNT.

Measure VDC on Servo

Interconnect B Cable P20,

Pin 22, and Pin 37.

Is the reading 5VDC?Is the reading 5VDC?

Exit FmNT, shut down

Windows NT, press the black

OFF (0) button on the

Operator’s Console, switch

Main Circuit Breaker to OFF

(0) position, and disconnect

Power Cable from the facility

outlet.

Is there continuity?Is there continuity?

Check continuity of Servo

Interconnect B Cable (Pinout

is 1 to 1).

XY Servo Interface PWA

(P/N 194036) has failed

Servo Interconnect B

Cable (P/N 06-4525-00)

has failed.

A

A

Solenoid Valve (P/N

197396 4-way or P/N

197397 Dual 3-way) has

failed

No

Yes

No

YesNo

Yes

No

Yes

No

Yes

No

Yes

Diagram Sheet 4-7-3

Pneumatics Fault Isolation Procedure - Pneumatics Verification

Loading...

Loading...