24 Rockwell Automation Publication KNX-SG001H-EN-P - December 2020

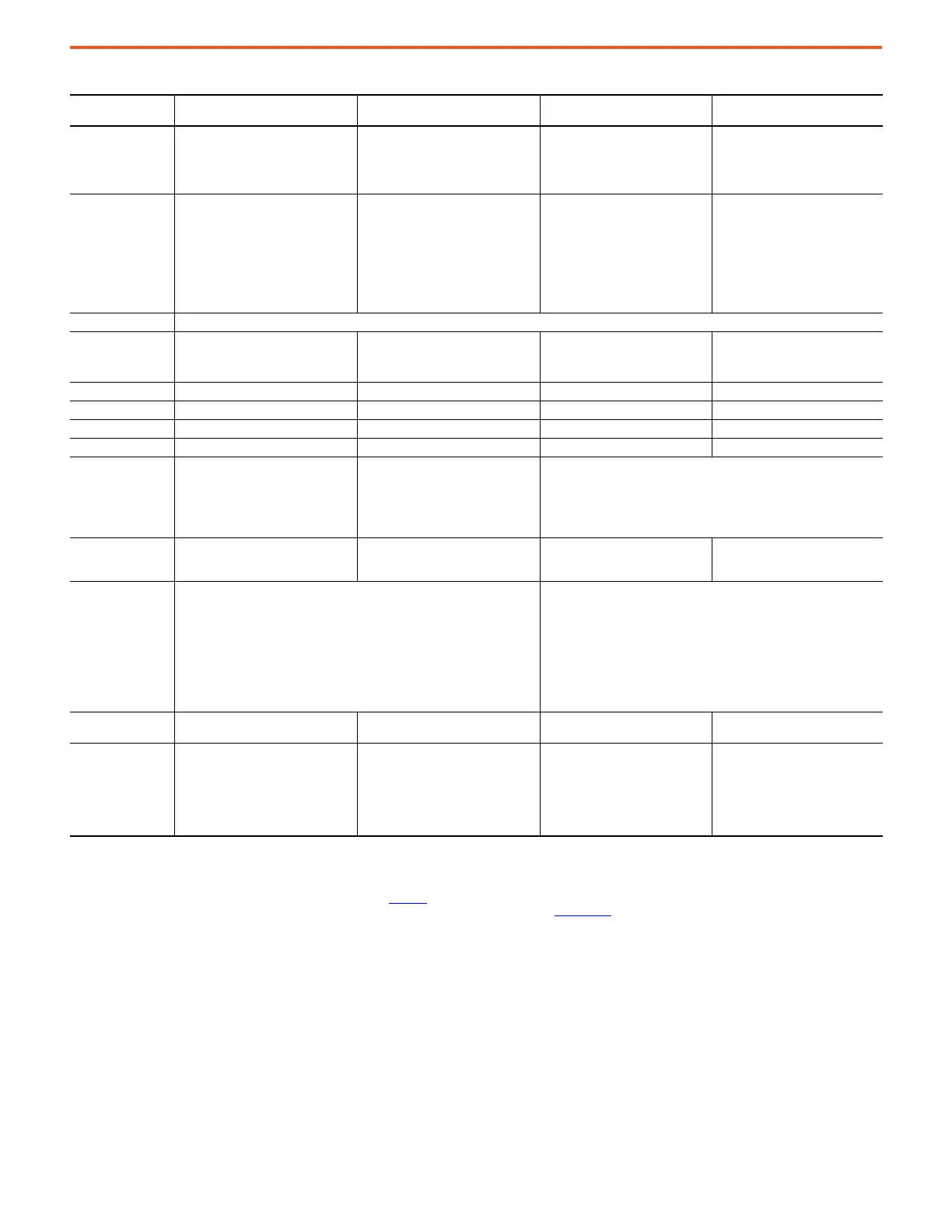

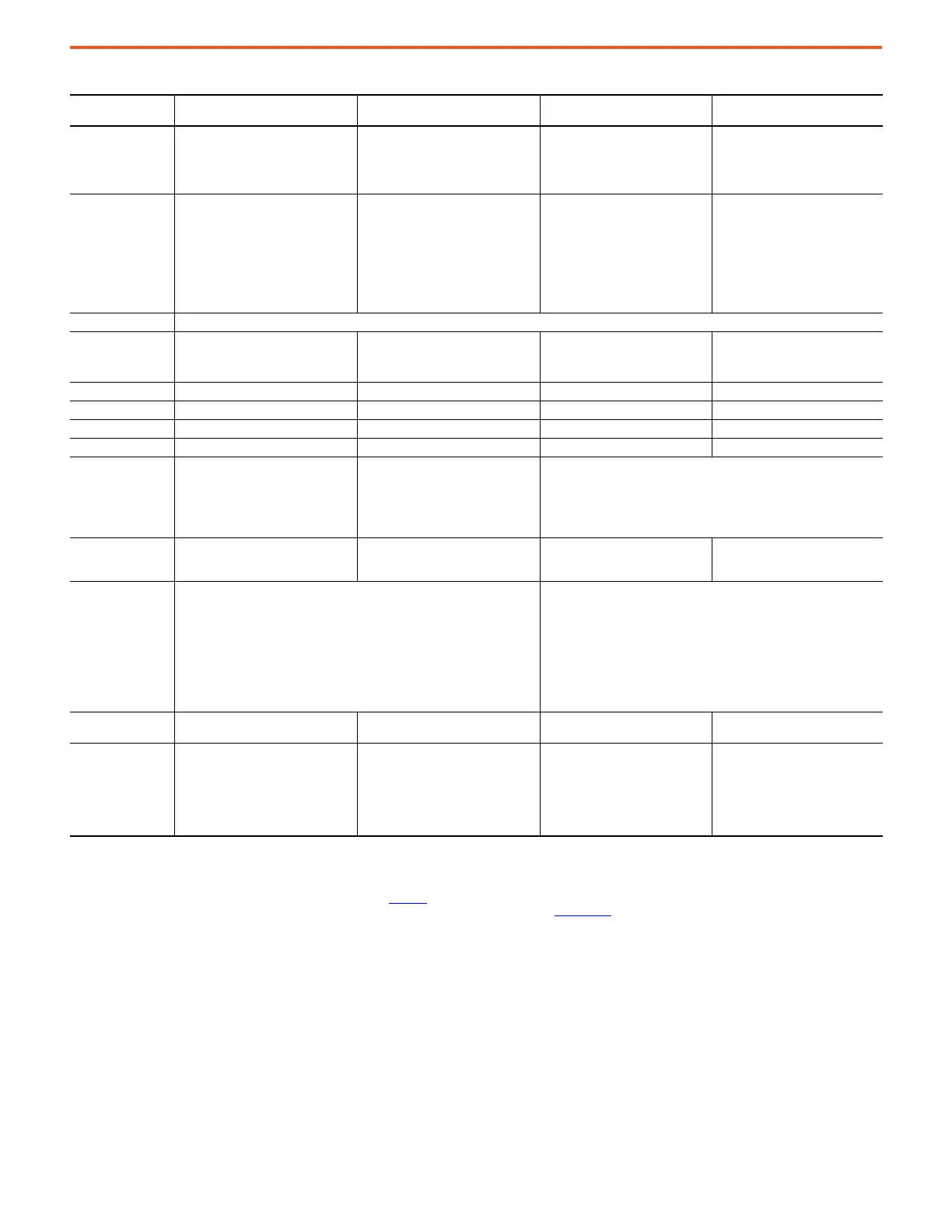

Product Features Comparison

Kinetix MP Servo Motors

Motor Features

Kinetix MPL

Low-inertia Motors

Kinetix MPM

Medium-inertia Motors

Kinetix MPF

Food-grade Motors

Kinetix MPS

Stainless-steel Motors

Main characteristics

• High torque to size ratio

•Smart Motor Technology

• Low rotor inertia

• High torque to size ratio

• Smart Motor Technology

• Medium rotor inertia

• Easy migration from 1326AB motors

• Configurable winding options,

brakes, and encoder feedback

• Low rotor inertia

• Specifically designed for sanitary

environments for use with high

pressure, highly caustic washdown

applications

• Low rotor inertia

Features

• 230V and 460V windings

• High-energy rare-earth magnets

• Shaft end threaded hole

• DIN connectors, rotates 180°

• Standard IEC 72-1 mounting

dimensions

• 230V and 460V windings

• Multiple winding speed options

• High-energy rare-earth magnets

• Shaft end threaded hole

• SpeedTec-ready DIN connectors,

rotates 180°

• Standard IEC 72-1 mounting

dimensions

• Food-grade epoxy coating

• 230V and 460V windings

• Shaft end threaded hole

• SpeedTec-ready DIN connectors,

rotates 180°

• Standard IEC 72-1 mounting

dimensions

• Smooth, passivated 300 series

stainless-steel cylindrical exterior

• Certified and listed to NSF/ANSI

Standard 169

• 230V and 460V windings

•Shaft end threaded hole

• Cable extensions, 3 m (9.8 ft)

• Standard IEC 72-1 mounting

dimensions

Motor type Brushless AC synchronous servo motors

Environmental ratings

• IP50 minimum, without shaft seal

(standard)

• IP66 with optional shaft seal

(1)

(1) IP66 with optional shaft seal and the use of Rockwell Automation factory-delivered 2090-Series cable connectors.

• IP50 minimum, without shaft seal

(standard)

• IP66 with optional shaft seal

(1)

• IP66/IP67 with shaft seal

(2)

(standard)

• Food grade grease on shaft seal

(2) IP66/IP67 with shaft seal (standard) and the use of Rockwell Automation factory-delivered 2090-Series cable connectors.

• IP66/IP67 with shaft seal

(2)

(standard)

•IP69K

(3)

(3) IP69K for 1200 psi motor washdown with shaft seal (standard), not including on-motor cable connector.

Continuous torque 0.26…163 N•m (2.3…1440 lb•in) 2.18…62.8 N•m (19.3…556 lb•in) 1.6…19.4 N•m (14…172 lb•in) 3.6…21.5 N•m (32…190 lb•in)

Peak torque 0.74…278 N•m (6.6…2460 lb•in) 6.6…154.2 N•m (58…1365 lb•in) 3.61…48.6 N•m (32…430 lb•in) 11.1…98 N•m (67.8…600 lb•in)

Speed Up to 8000 rpm Up to 7000 rpm Up to 5000 rpm 3000 and 5000 rpm

Motor rated output 0.16…18.6 kW 0.75…7.50 kW 0.73…4.1 kW 1.3…3.5 kW

Feedback options

(4)

(4) Not all drive families accept incremental and resolver feedback options.

• Multi-turn, high-resolution

absolute position

• Single-turn, high-resolution

absolute position

•Incremental encoders

•Resolver

• Multi-turn, high-resolution

absolute position

• Single-turn, high-resolution

absolute position

•Resolver

• Multi-turn, high-resolution absolute position

• Single-turn, high-resolution absolute position

Motor options

•24V DC brake

•Shaft seal kit

• Keyless shaft (limited frame sizes)

•24V DC brake

•Shaft seal kit

• Positive air pressure kit

•24V DC brake

•Shaft seal kit

• Positive air pressure kit

•24V DC brake

• Shaft seal kit with slinger

• Positive air pressure kit

Compatible

(5)

(6)

drives

(5) For Kinetix 2000 drive specifications, refer to Additional Resources on page 233

for links to the applicable technical data and design guide publications.

(6) For PowerFlex 755 drive specifications, refer to the PowerFlex Low Voltage Drives Selection Guide, publication PFLEX-SG002

.

• Kinetix 5700

• Kinetix 5500

• Kinetix 5300

• Kinetix 5100

• Kinetix 6200/6500

• Kinetix 6000

• Kinetix 7000

• Kinetix 300/350

• Kinetix 2000

• PowerFlex® 755

• Kinetix 5700

• Kinetix 5500

• Kinetix 5300

• Kinetix 5100

• Kinetix 6200/6500

• Kinetix 6000

• Kinetix 300/350

• Kinetix 2000

Servo cable

compatibility

2090-CxxM7xx cables 2090-CxxM7xx cables 2090-CxxM7xx cables 2090-CxxM7xx cables

Typical applications

• Packaging

•Converting

• Material handling

• Electronic assembly

• Automotive

•Printing

• Web handling

•Converting

• Automotive

• Food packaging

• Volumetric filling

• Form, fill, seal

• Food handling

• For meat and poultry applications,

the Kinetix MPS stainless steel

motors are recommended

•Meat and poultry

• Food slicing and filling

• Raw food handling

•Processing

• Life science

•Consumer products

Loading...

Loading...