Design Guidelines

Transport System Options

132 MagneMotion

Rockwell Automation Publication MMI-UM002F-EN-P - October 2022

Precision Rail Lubrication

The rails and bearings are an open system that requires continuous lubrication. To avoid

breakdown of the lubrication, the precision rails must always have a thin film of oil across the

entire rail system and the bearings in the vehicles. This coating provides both lubrication and

environmental protection. The interval to resupply the lubrication depends on the distance

traveled, load on the vehicles, and environmental factors. There are several different methods

for lubricating the rails as described here. Use 68 viscosity mineral oil, such as Kluber 4

UH1-68N, to lubricate the bearing rails.

Manually Lubricate the Rails

Lubricate the rails manually when needed (see Manually Lubricate the Precision Rails on

page 362).

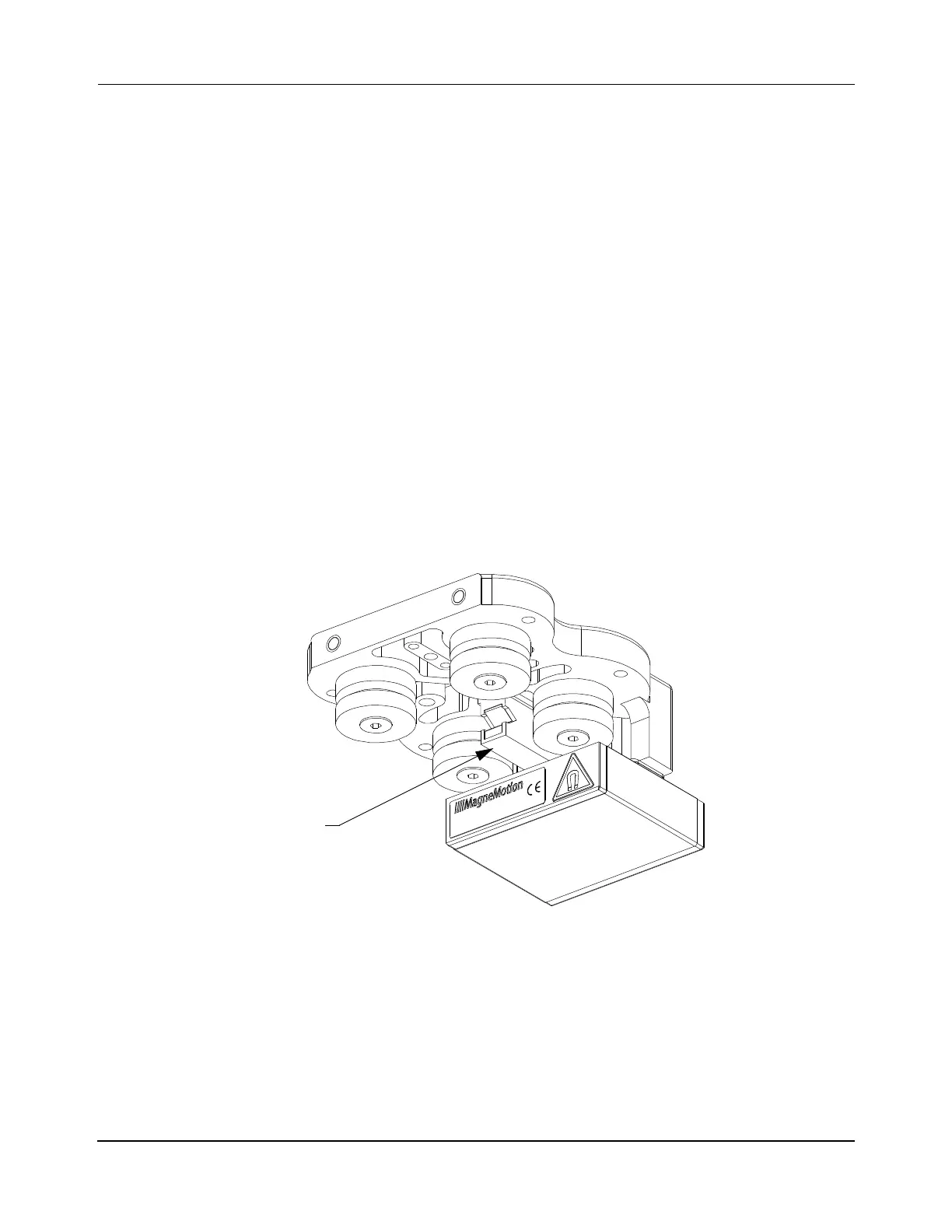

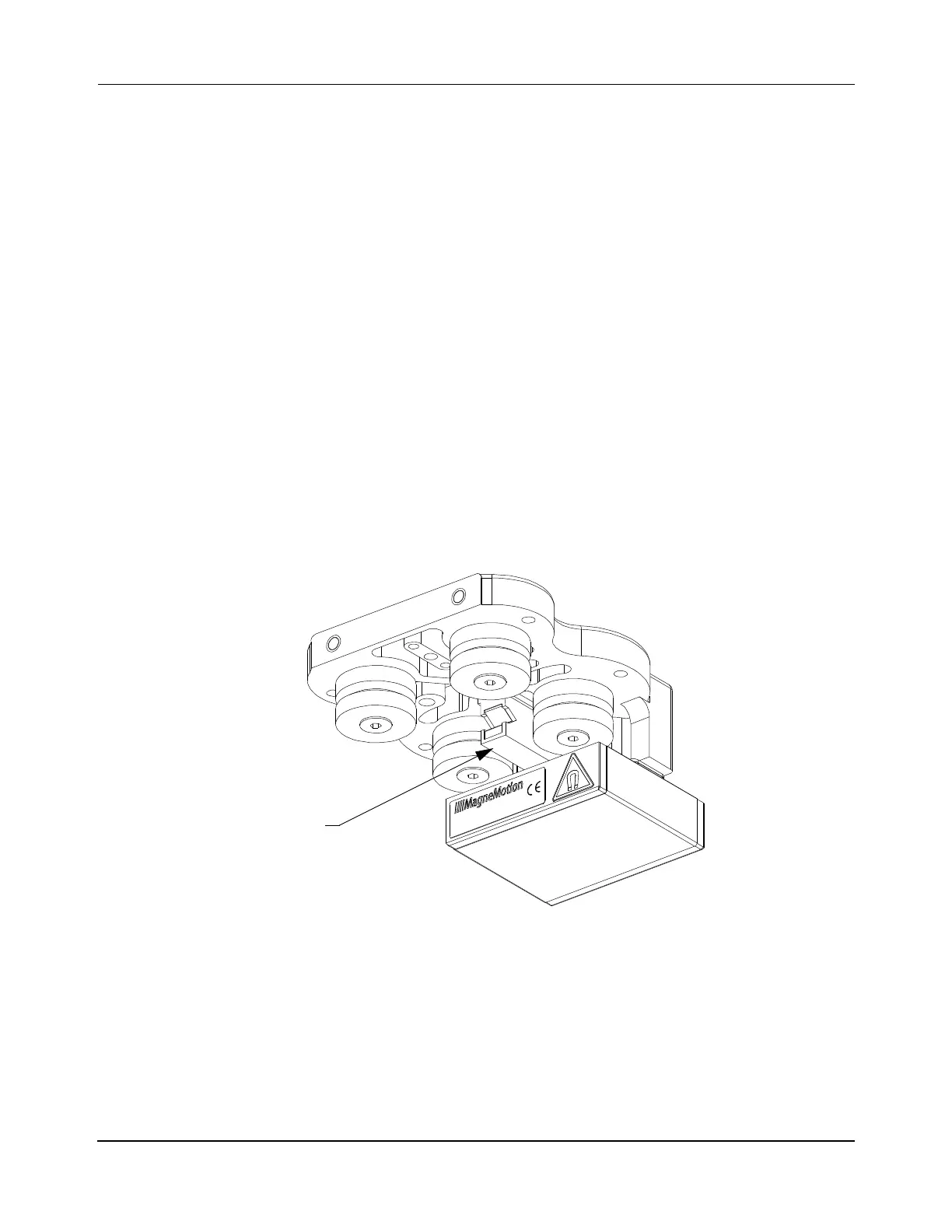

Use Vehicle Mounted Lubricators

Install lubricators on the vehicles to provide continuous lubrication (see Install/Replace the

Lubricators on Precision Rail Vehicles on page 433). Lubricators are required for each side of

the rail. Figure 3-58 shows the single array vehicle with one lubricator. This configuration

requires a second vehicle with a lubricator for the other side of the rail.

Figure 3-58: Lubricator on Single Array Vehicle

Loading...

Loading...