Maintenance

Preventive Maintenance

358 MagneMotion

Rockwell Automation Publication MMI-UM002F-EN-P - October 2022

Tandem Wheeled Pucks Procedure

The bogie attachment points and the wheels on the bogies that are used on the tandem

wheeled puck must be inspected regularly to help maintain proper operation.

1. Remove the tandem wheeled puck from the MagneMover LITE transport system (see

Replace Pucks on page 399).

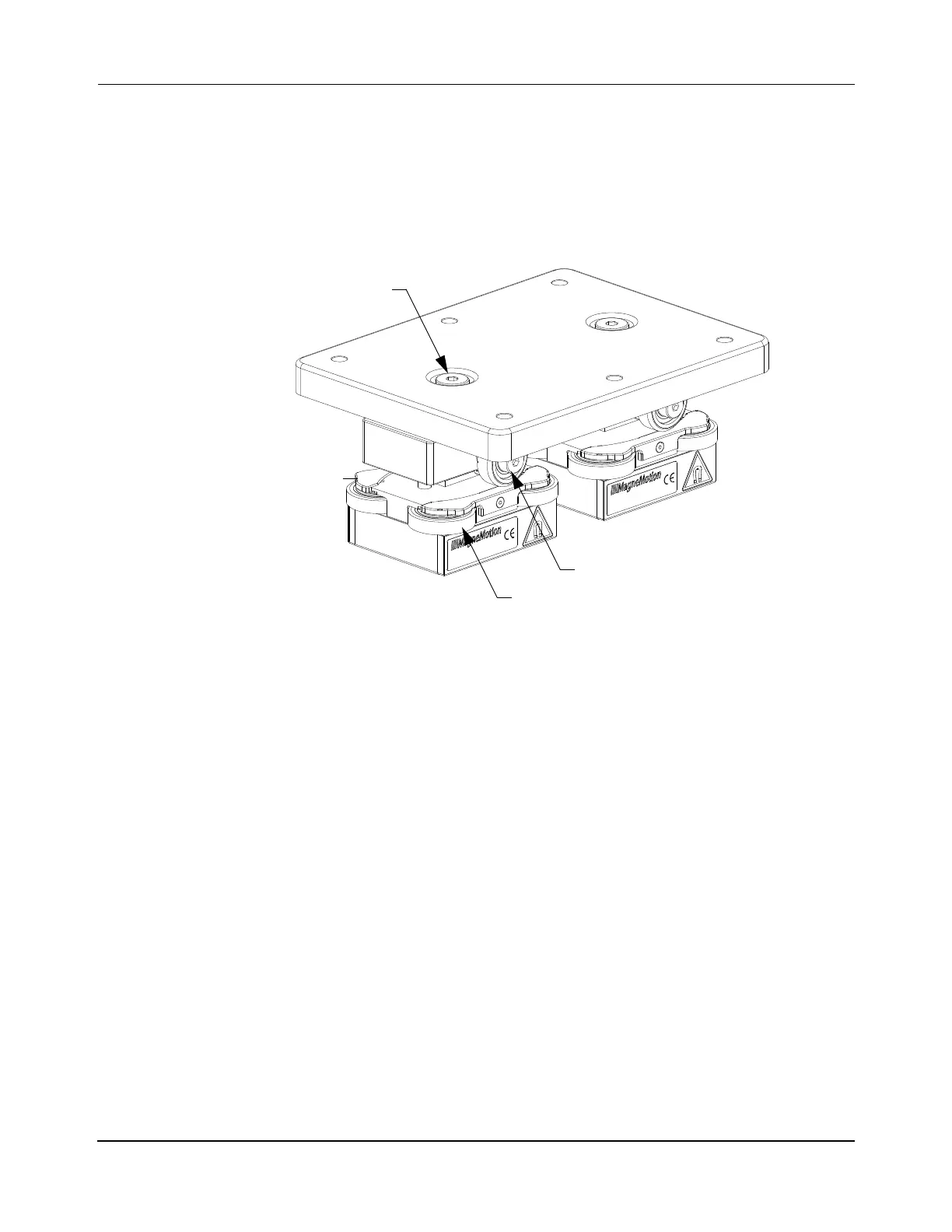

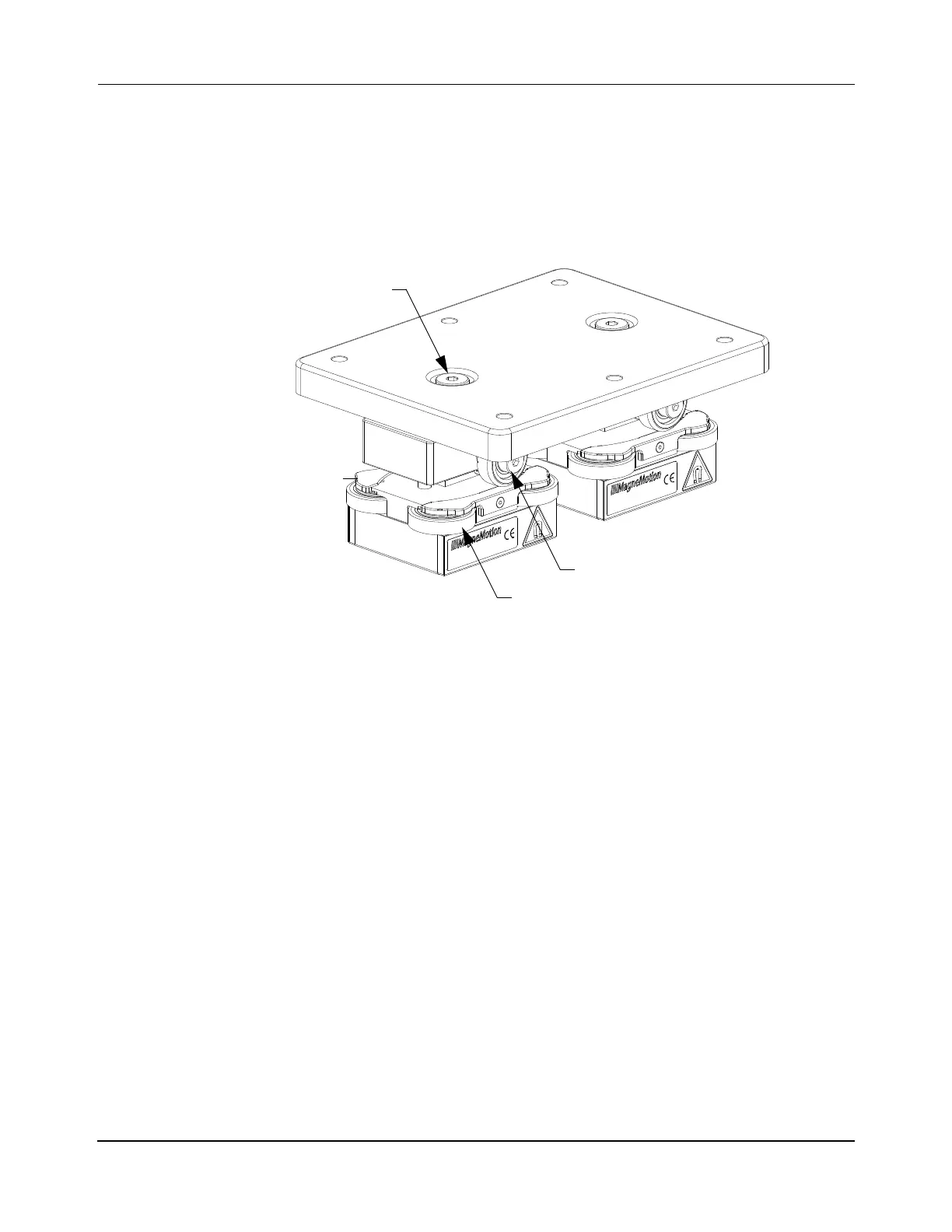

Figure 7-5: Tandem Wheeled Puck Wear Point Inspection

2. Inspect the bogie pivot points for high rotating friction (see Figure 7-5).

• If either of the pivot points are showing excessive friction, clean or replace the

pivot point bearings, see Replace Tandem Wheeled Puck Wear Surfaces on

page 419.

3. Inspect the wheels for high rotating friction and tread damage (see Figure 7-5).

• If any wheels are showing excessive accumulation of particles, clean the wheel

set, see Wheeled Puck Cleaning on page 354.

• If any wheels are showing excessive friction or tread damage, replace the

wheel set, see Replace Tandem Wheeled Puck Wear Surfaces on page 419.

4. Replace the puck on the transport system (see Replace Pucks on page 399).

Lateral Guide Wheels

Pivot Points

Suspension Wheels

Loading...

Loading...